Automatic Stand Up Pouches Bags Nuts Packing Machine With 8 Heads

- Type:

-

Multi-Function Packaging Machine

- Packaging Material:

-

plastic, Paper

- Packaging Type:

-

Stand-up Pouch, Bags, Film, Pouch

- Function:

-

FILLING, Sealing

- Application:

-

Food, Beverage, MEDICAL, Chemical

- Automatic Grade:

-

Automatic

- Driven Type:

-

Electric

- Voltage:

-

220V 50-60Hz

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Dimension(L*W*H):

-

1630*1100*1550mm

- Certification:

-

ISO

- After-sales Service Provided:

-

Field installation, commissioning and training

- Warranty:

-

1 Year

- Product name:

-

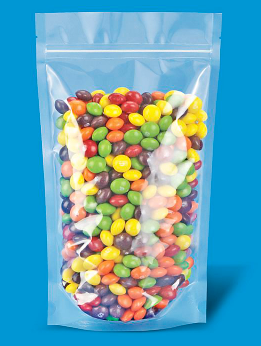

stand-up pouch nuts / snack packing machine

- Usage:

-

nuts, snacks, grain, granule,powder packing

- Main Function:

-

Pouch Filling Sealing Packing

- Machine type:

-

Multi-function Packing Machine

- Packing speed:

-

25- 50 Bags/minute

- Bag material:

-

OPP/CPP,PET/CPP,PET/AL/PE,PE/Paper Bag type Any bag type you want

- Bag size:

-

L)15-250(W)20-150mm

- Measuring range:

-

100-1000g

- G.W:

-

900kg

- Control system:

-

PLC+English Screen

- Supply Ability:

- 5 Set/Sets per Month Stand up pouch packing machine

- Packaging Details

- Fumigation wooden cases, which are well sealed and strong enough for long term trip, and suitable for multi-times loading & unloading by forklift.

- Port

- Shanghai

- Picture Example:

-

- Lead Time :

-

Quantity(Sets) 1 – 1 >1 Est. Time(days) 30 To be negotiated

Automatic Stand Up Pouches Bags Nuts Packing Machine with 8 heads

The equipment is mainly used in automatic particle counting packages. Through the material delivered to the automatic measurement device of hoist, after the accurate measurement based on the specified parameters, to the level to the Rotary packing machines for automatic bagging and sealing, output. The whole automatic control of equipment saved resources, increased productivity.

Function and Characteristics:

1.Easy to operate, adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system,

the man-machine interface is friendly.

2.Automatic checking function: no pouch or pouch open error, no fill, no seal. The bag can be used again, avoid wasting packing materials and raw materials.

3.Safety device: machine stop at abnormal air pressure, heater disconnection alarm.

4.The machine is easy to clean, easy maintenance.

5.The part where touch to the material is made of stainless steel

Working Process:

Pouch picking unit→ coding date → pouch opening → air flushing → filling → auxiliary pouch stretching → heat seal → finishing shape → outlet

Parameters:

*Put the machine onto bottom iron support

*Bind foot stool with iron bar on the bottom support by iron wire tightly.

*Use PE film to Shrink the machine well

*Wrapped the wooden case with metal frame

*Pack the complete machine into container by forklift truck.

*Deliver them by sea or by air

*30sets/20 feet Container

Tomato paste production line

100% Response Rate

Filling machine

100% Response Rate

Milk processing line

100% Response Rate