Labeling Machine For Composite Can

- Type:

-

LABELING MACHINE

- Packaging Material:

-

Glass, Paper, plastic, tinplate can labeling machine

- Packaging Type:

-

Bags

- Application:

-

Beverage, Food, MEDICAL, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles, tinplate can labeling machine

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, tinplate can labeling machine

- After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location:

-

None

- Showroom Location:

-

None

- Condition:

-

New

- Automatic Grade:

-

Automatic

- Driven Type:

-

Electric

- Voltage:

-

220V/50HZ

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Dimension(L*W*H):

-

2000(L)*950(W)*1260(H) (mm)

- Weight:

-

200kg

- Certification:

-

ISO

- After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Overseas service center available

- Warranty:

-

5 years

- Key Selling Points:

-

Easy to Operate

- Marketing Type:

-

New Product 2020

- Machinery Test Report:

-

Provided

- Video outgoing-inspection:

-

Provided

- Warranty of core components:

-

3 months

- Core Components:

-

PLC, Pressure vessel, Gear, Motor, Engine, Bearing, Gearbox, Pump, tinplate can labeling machine

- Product name:

-

tinplate can labeling machine labelling machine for composite can

- Bottle type:

-

Round Square Flat Pet Bottle

- Other name:

-

automatic labeling machine

- Function:

-

Auto Sticker Labeling Equipment

- Model:

-

JPF-TB4586

- Labeling speed:

-

20-200pcs/min

- Advantage:

-

Economy Labeling Machine

- Material:

-

Stainless Steel

- Usage:

-

Lable

- Supply Ability:

- 100 Set/Sets per Month

- Packaging Details

- package in cartonstinplate can labeling machine

- Port

- Shanghai

1, Performance features:

1. The machine is suitable for labeling cans. After the can is rolled into the machine, it is driven to roll by the belt pressed on the can. When the can passes through the heat

At the glue melting station, the cans are coated with hot-melt glue. As the cans move forward, the glue on the cans is pressed to the front of the label,

The label was glued up and began to roll on the can. At the same time, the gluing mechanism at the end of the label also applies glue to the end of the label.

As the can moved on, the label was rolled onto the can. Then the belt is rolled and driven out of the machine.

2. The machine has an alternate supply mechanism, so it does not need to stop when adding the standard.

3. The glue supply at the end is controlled by the can, with glue supplied by can, but not without can.

4. The machine adopts frequency conversion speed regulation, which can be adjusted at any time according to the production needs.

5. The machine is simple to replace the tank type, less replacement parts, only glue at both ends of the label, the amount of glue used is small, and the cost of labeling is low.

2, Suitable range:

1. This machine is a tin can labeling machine, which is suitable for tin can labeling;

2. It can quickly change the size of tinplate can, and the operation is simple, neat, beautiful and clean.

3, Technical parameters:

Labeling capacity: 200-500 cans / min (varies with can size)

Suitable can size: diameter: Φ 40-120mm, height: 250mm

Label size: width: 23-254mm; length: 117-380mm

Label adhesive: hot melt adhesive + quick drying adhesive

Power supply: three phase; 380V (or customized as required)

Electric power: 3kw

Compressed air: 2-4kg / m2; 10 L / min

Overall dimension: length 1856mm × width 750mm × height 1250mm

Weight: 750KG

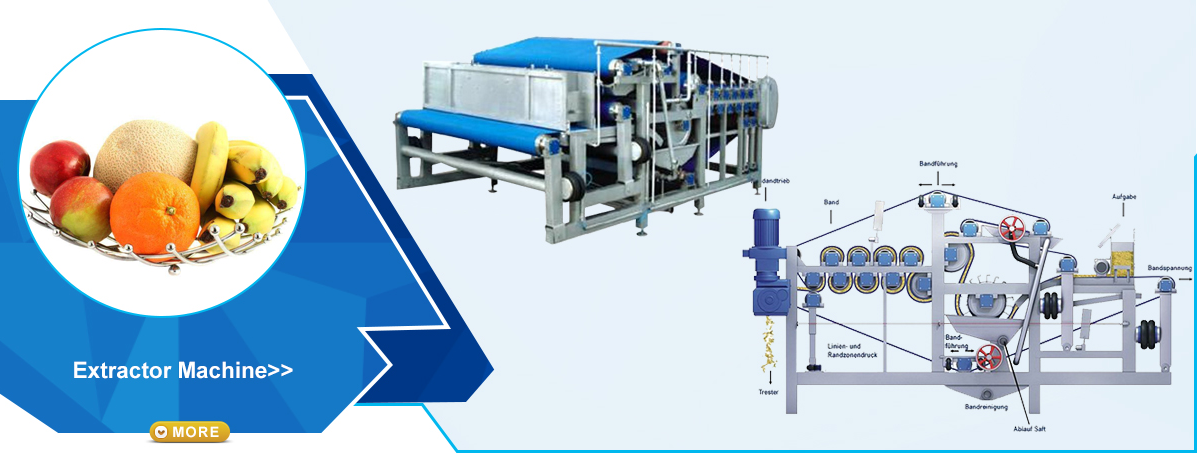

Our main production line

1 Tomato paste / puree / jam / concentrate, ketchup, chilli sauce , other fruit & vegetables sauce / jam processing line

2 Fruit & vegetables ( orange , guava, cirtrus, grape, pinapple, cherry, mango, apricot.etc. ) juice and pulp processing line

3 Pure, mineral water, Mixed beverage, drink (soda, Cola, Sprite, carbonated beverage, no gas fruit drink, herbal blend drink, beer,cider, fruit wine .etc. ) production line

4 Canned fruit & vegetables ( tomato, cherry, beans, mushuroom, yellow peach, olives, cucumber, pineapple, mango, chili, pickles and so on. ) production line

5 Dried fruit & vegetables ( dried mango, apricot, pineapple, raisin, blueberry .etc. ) production line

6 Dairy (UHT milk, pasteurized milk, cheese, butter, yogurt, milk powder, margarine, ice cream)production line

7 Fruit and vegetable powder (Tomato, pumpkin, cassava powder, strawberry powder, blueberry powder, bean powder, etc. ) production line

8 Leisure snack (Dried freeze-dried fruit, puffed food, french fried potato chips, etc. ) production line

Pre-sales service

We can suggest customer the most suitable machine according to their formula and Raw material. “Design and development”, “manufacturing”, “installation and commissioning”, “technical training” and “after sales service”. We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

After-sale service

1.Installation and commissioning: We will send experienced engineering and technical personnel to be responsible for the installation and commissioning of the equipment until the equipment is qualified to ensure that the equipment is in time and put into production;

2.Regular visits:To ensure the long-term stable operation of the equipment, we will be based on customer needs, provide one to three times a year to come to technical support and other integrated services;

3.Detailed inspection report: Whether the inspection regular service, or the annual maintenance, our engineers will provide a detailed inspection report for the customer and the company reference archive, in order to learn the equipment operation at any time;

4.Fully complete parts inventory: In order to reduce the cost of parts in your inventory, provide better and faster service, we prepared a complete inventory of parts of equipment, to meet customers possible period of want or need;

5.Professional and technical training:In order to ensure the performance of the customer’s technical personnel to become familiar with the equipment, correctly grasp the equipment operation and maintenance procedures, in addition to install on-site technical training. Besides, you also can hold all kinds of professionals to the factory workshops, to help you faster and more comprehensive grasp of technology;

6.Software and consulting services:In order to allow your technical staff to have a greater understanding of the equipment related counseling, I will arrange to send the equipment regularly sent to the advisory and latest information magazine.No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-l