Automatic Agricultural Chemicals / Pesticide Filling Production Line

- Packaging Material:

-

wood

- Type:

-

Filling Machine

- Condition:

-

New

- Application:

-

Beverage, Food, Machinery & Hardware, MEDICAL

- Packaging Type:

-

case

- Automatic Grade:

-

Automatic

- Driven Type:

-

Electric

- Voltage:

-

220V/380V

- Power:

-

4.5kw

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

jumpfruits

- Model Number:

-

JPMC-1008

- Dimension(L*W*H):

-

2300(L)x1500(W)x1900(H)MM

- Weight:

-

850KG

- Certification:

-

ISO,CE

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product Name:

-

pesticide manufacturing machine

- Function:

-

Filling Machine

- Material:

-

SUS304

- Capacity:

-

1000-6000b/h

- Warranty:

-

12 Months

- Usage:

-

pesticide filling production line

- Processing Types:

-

Normal Pressure Filling

- Filling material:

-

Flowing Liquid

- Bottle type:

-

Round Bottle

- Name:

-

liquid Filling Packing Machine

- Supply Ability:

- 10 Set/Sets per Week pickles production line

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- Shanghai port

- Lead Time :

- 3-7 days when machine in stock,30 days for customize machine

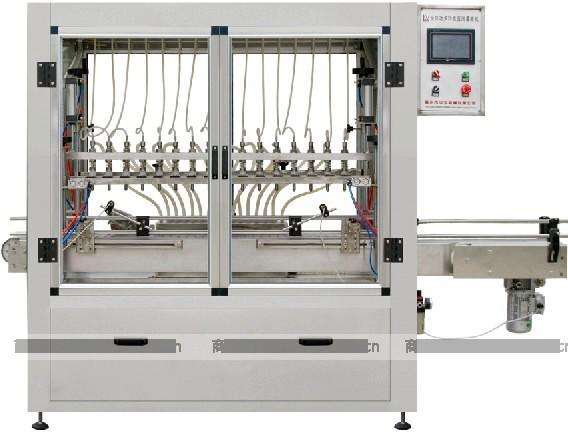

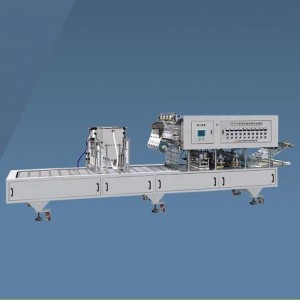

Pesticide filling production line Product Description:The pesticide filling production line is a filling production line consisting of 8 filling machines and a capping machine. This machine is designed for the filling of pesticides. Similar products are also applicable.

Product Features of Pesticide Filling Line

1. High degree of automation, simple operation, stable operation, can effectively save enterprise costs and increase production efficiency.

2. Each stand-alone machine can independently complete its work, have an independent operating system, and numerical control display and other electrical components to control the adjustment of various parameters and display settings. Can help companies achieve standardized production

3, each single machine linkage, separation and fast, and adjust quickly and simply, so that each process of production to ensure coordination.

4, each single machine can adapt to a variety of specifications of the material bottle packaging, and fewer adjustments.

5. The packaging production line adopts international new process design and meets GMP standards.

6. The production line of pesticide filling production line runs smoothly, with convenient combination of various functions and convenient maintenance. Various production combinations can be carried out according to the technical requirements of users’ respective products.

Pesticide filling production line technical parameters

Filling head number: 8

Lower cover plate number: 1

Under cover number: 1 set

Capping head number: 1 set

Air source: 5-8 kgf/cm2

Filling form: Self-flow multihead lifting filling

Filling speed: 50-80 bottles/minute

Filling error: ≤±1%

Covering speed: >80 bottles/minute

Capping speed: >80 bottles/minute

Rack Material: Stainless Steel

Delivery speed: 5-15 meters/minute

Filling conveyor width: 114 mm.

Filling conveyor belt material: POM race steel chain piece

Line height above ground: 750 mm ± 50 mm adjustable

Whole line power: 2KW/380V AC three-phase four-wire power supply

Program Control: Imported PLC with Touch Screen HMI

Production line length: 8.5 meters

Main Technical Parameters:

Own tomato planting base in Xinjiang+Machinery processing line+15 years export experience+professional customerize service=your reliable business partner

1.Planting base in Xinjiang,producing tomato products(paste/powder,etc) in world top quality,with production capability of over 1000T/day

2.Factory of machinery and engineering vegetables and fruit paste processing,juice drink processing and fruit powder process etc.,absorbing world advanced technology.

3.15 years export experience, easily transport cargo to your door

4.customerized service, revise our products or OEM for your requirements

After-sale service

1.Installation and commissioning: We will send experienced engineering and technical personnel to be responsible for the installation and commissioning of the equipment until the equipment is qualified to ensure that the equipment is in time and put into production;

2.Regular visits:To ensure the long-term stable operation of the equipment, we will be based on customer needs, provide one to three times a year to come to technical support and other integrated services;

3.Detailed inspection report: Whether the inspection regular service, or the annual maintenance, our engineers will provide a detailed inspection report for the customer and the company reference archive, in order to learn the equipment operation at any time;

4.Fully complete parts inventory: In order to reduce the cost of parts in your inventory, provide better and faster service, we prepared a complete inventory of parts of equipment, to meet customers possible period of want or need;

5.Professional and technical training:In order to ensure the performance of the customer’s technical personnel to become familiar with the equipment, correctly grasp the equipment operation and maintenance procedures, in addition to install on-site technical training. Besides, you also can hold all kinds of professionals to the factory workshops, to help you faster and more comprehensive grasp of technology;

6.Software and consulting services:In order to allow your technical staff to have a greater understanding of the equipment related counseling, I will arrange to send the equipment regularly sent to the advisory and latest information magazine.No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Why choose us?

1.”Quality is priority”. we always attach great importance to quality control from the very beginning to the very end;

2.we have a professional manufacture experience and machining equipment;

3.we are factory ,we can provide you the super quality and very competitive price;

4.company has a quality,young,innovative and strong scientific research technical team

Is your price competitive?

surely we will give you best factory price based on superior product and service.

Any warranty?

1.one year equipment warranty after successful installation & commissioning of equipment and maintenance for lifelong time;

2.free installation and test before sending and free training for operation

3.advice for the solutions best for customers requirements

How about the test running & installation?

1.Before delivery, we finish the test over 3 times.

2.If you take integral design, no need to installation at all. If parted design, we can send our technicians to your place if necessary.

How to choose your wanted type?

1.tell us your requirement of the productivity.

2.You know about our machines ,the just tell us the type.

3.Give us the detailed information about your raw material,Picture will be best