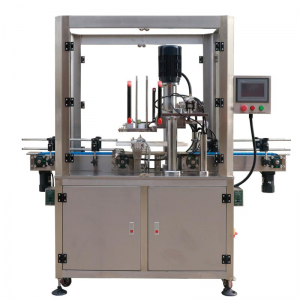

Metal Aluminum Tin Can Drink Filling And Sealing Machine 10000cans/h

- Packaging Material:

-

metal, tin can

- Type:

-

Filling Machine

- Condition:

-

New

- Application:

-

Beverage

- Packaging Type:

-

CANS, glass bottle, jars

- Automatic Grade:

-

Automatic

- Driven Type:

-

Electric

- Voltage:

-

380V 50Hz

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

Jumpfruits

- Dimension(L*W*H):

-

2500mm*1900mm*2100mm

- Weight:

-

2900kg

- Certification:

-

ISO

- After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

- Warranty:

-

1 Year, 1 Years

- Product name:

-

tin can filling line

- Name:

-

tin cans Filling sealing Machine

- Processing Types:

-

Automatic Bottle Filling Sealing Machine

- Usage:

-

tin can Beverage, beer, juice Packaging

- Filling material:

-

Flowing Liquid

- Material:

-

Stainless Steel 304

- Bottle type:

-

tin cans, pop cans,aluminum cans, metal cans

- Capacity:

-

8000-10000 cans /h

- Cans type:

-

206 with cover 202 (250ml)

- Supply Ability:

- 20 Set/Sets per Year tin can sealing machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- Shanghai

Two-in-one filling and sealing machine for tinplate / aluminum tin cans

Uses and characteristics

The filling seal adopts the same power device to ensure the synchronous operation, the equipment without box structure maintenance is very convenient. Adopting pneumatic control automatic lower cover without tank body contact, adopting equal level tank technology, the production capacity is variable frequency speed regulation, more than 90% appearance material is stainless steel, which ensures the beauty and hygienic requirement of the whole machine. In order to improve the vacuum in the tank.

This machine is suitable for filling and sealing of juice, tea drinks and other drinks. It has the characteristics of fast filling and sealing speed, consistent height between the liquid level and the opening of the tank after filling, smooth operation of the whole machine, good sealing quality, beautiful appearance, convenient use and maintenance, touch screen operation, frequency conversion speed regulation, and so on. Is the ideal beverage factory filling and sealing equipment.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

If you are interested in our production machine, pls contact Nina by

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.