Big Scale Industrial Pasta Production Line

Automatic Pasta Production Line

Equipment list:Mixer–Screw conveyor-DLG150 Extruder–Cutter–Flat conveyor–Hoister–Dyer–Hoister–Dryer–Cooling machine–Packing machine

1.Feeding System:Installed in the main machine, which feeds materials spirally, and the quantity can be adjusted. This system includes engine, screw, blender and machine shelf.

2.Extruding System:Adopts the crafts what can make the materials ripe in the low temperature by blending, cutting and extruding. Temperature control is set strictly on the roller and screw to reach criteria the materials require.

3. Cutting System:The shelf is fixed on the head of the moulds; and turns and cuts the materials motivated by the belt wheel.

4.Heating System:Divides five areas, and the heating temperature of which can be adjusted separately.

5.Transmitting System:The motive power from the main engine is transmitted to the screw through the triangle belt and decelerator.

6.Controlling System:Can control all the components of the main machine centrally.

7.Vacuum Pump.For the pasta and macaroni,the big problem is with bubbles and air inside.With the vacuum pump,which can extract air from feeding part,so there will be no any air and bubbles inside the pasta and macaroni,it will not easy broken and taste also very strong and good.

Mixer

Power:4kw

Dimension(m):1.05*0.8*1.4

Mixing time :3 minutes

Volume:40Kg/batch

Net weight:180kg

Stainless steel mixer shaft in the mixer tank to mix the raw material,water and other additives.

Screw Conveyor

Power:1.1kw

Dimension(m):3.2*0.4*2.1

Net weight:100kg

The raw material can be conveyed in the stainless steel roller without any leaking, dust pollution to the extruder.

Extruder

Power:102kw

Dimension(m):3.9*1.15*1.9

Net weight:3200kg

In the process of inflation, the materials in the sealed roller are pushed by the screw, getting the high pressure and the cutting force, While lowing the pressure of the materials next to the exit, plastic gel is extruded out and instantly cools and geometrical shapes, by means of changing the mould.Its shape can be spiral, shell, ring, pipe, square pipe and so on.

Hoister

Power: 0.75kw

Dimension(m): 2.2*0.7*2.2

Net weight:77kg

Conveying the product to the 5 layer 5 meter oven.

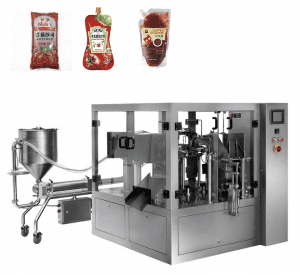

Packaging & Shipping

Our main production line

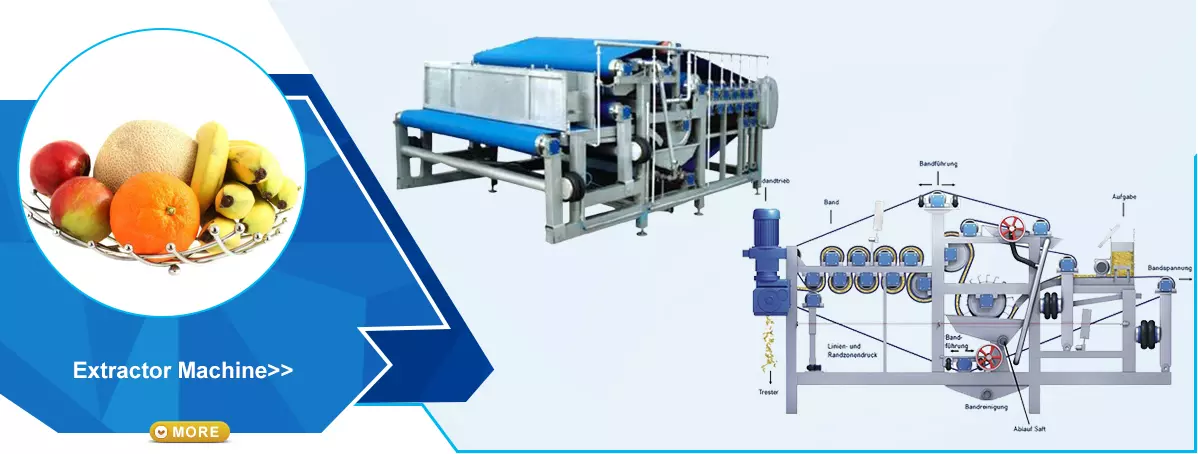

1Tomato paste / puree / jam / concentrate, ketchup, chilli sauce , other fruit & vegetables sauce / jam processing line

2Fruit & vegetables ( orange , guava, cirtrus, grape, pinapple, cherry, mango, apricot.etc. ) juice and pulp processing line

3Pure, mineral water, Mixed beverage, drink (soda, Cola, Sprite, carbonated beverage, no gas fruit drink, herbal blend drink, beer,cider, fruit wine .etc. ) production line

4Canned fruit & vegetables ( tomato, cherry, beans, mushuroom, yellow peach, olives, cucumber, pineapple, mango, chili, pickles and so on. ) production line

5Dried fruit & vegetables ( dried mango, apricot, pineapple, raisin, blueberry .etc. ) production line

6Dairy (UHT milk, pasteurized milk, cheese, butter, yogurt, milk powder, margarine, ice cream)production line

7Fruit and vegetable powder (Tomato, pumpkin, cassava powder, strawberry powder, blueberry powder, bean powder, etc. ) production line

8Leisure snack (Dried freeze-dried fruit, puffed food, french fried potato chips, etc. ) production line