Small tomato paste processing plant with factory price

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

OEM

- Type:

-

tomato paste processing line

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

80 TONS

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

ISO 9001,CE

- Warranty:

-

2 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

small tomato paste machine

- Material:

-

304 Stainless Steel

- Name:

-

tomato paste production line

- Application:

-

kinds of jams making

- Function:

-

Multifunctional

- Usage:

-

Industrial Usage

- Capacity:

-

200kg-50t/h

- Feature:

-

Easy Operation

- Item:

-

Automatic Fruits jams Machine

- Color:

-

Customers' Requirements

- 3 Set/Sets per Month small tomato paste machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- Shnaghai

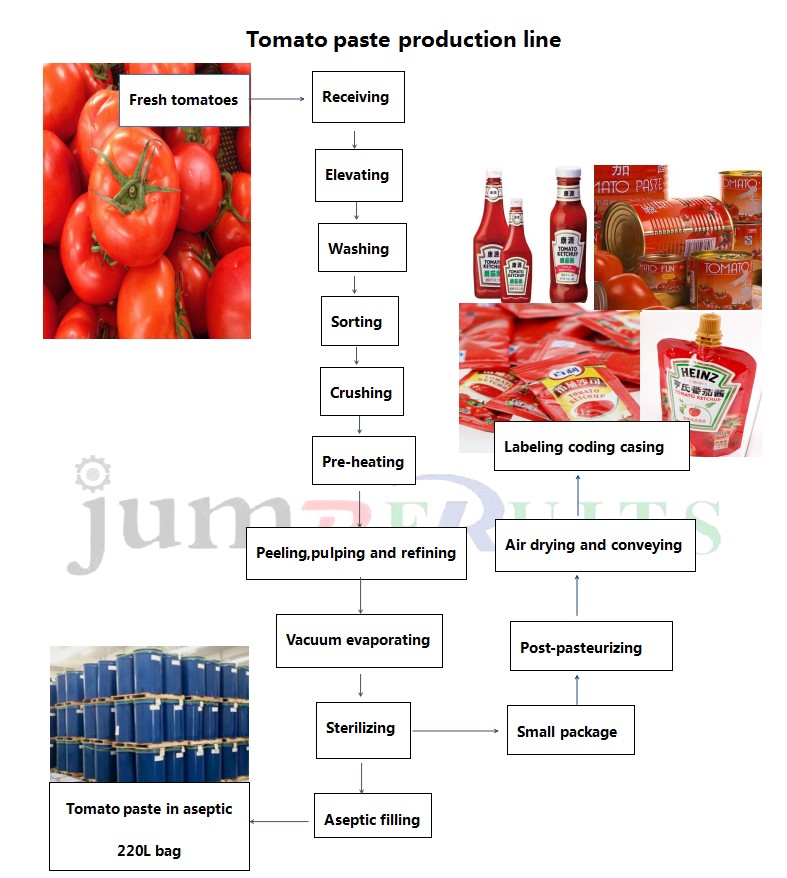

2.The whole line composition:

A: promotion system of the original fruits, cleaning system, sorting system, crushing system, pre-heating sterilization system, pulping system, vacuum concentration system, sterilization system, aseptic bag filling system

B: pump → blending drum → homogenization →deaerating → sterilization machine → washing machine → filling machine → capping machine → tunnel spray sterilizer → dryer → coding → boxing

3. The final product concentration: Brix 28-30%, 30-32% cold broken and heat broken, 36-38%

Select stainless steel bracket, food-grade and hard plastic or stainless steel scraper, smoothing blade architecture to prevent the fruit jam; Using imported anti-corrosion bearings, double-sided seal; with continuously variable transmission motor, variable frequency Speed and low operating costsTitle goes here.

Stainless steel roller conveyor, rotation and solution, a full range of check, no need ends. Manmade fruit platform, painted carbon steel bracket,stainless steel antiskid pedal,stainless steel fence.

C. Crusher

Fusing Italian technology, multiple sets of cross-blade structure, crusher size can be adjusted according to customer or specific project requirements, it will increase the juice juice rate of 2-3% relative to the traditional structure , which is suitable for production of onion sauce, carrot sauce, pepper sauce , apple sauce and other fruits and vegetables sauce and products

D. Double-stage pulping machine

It have tapered mesh structure and the gap with load can be adjusted, frequency control, so that the juice will be cleaner; Internal mesh aperture are based on customer or specific project requirements to order

E. Evaporator

Single-effect, double-effect,triple-effect and multi-effect evaporator, which will save more energy; Under vacuum, continuous low temperature cycle heating to maximize the protection of nutrients in the material as well as the originals. There are steam recovery system and double times condensate system, it can reduce the consumption of steam;

F. Sterilization machine

Having obtained nine patented technology, take full advantages of the material’s own heat exchange to save energy– about 40%

F. Filling machine

Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return; Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ; In the filling process,using turntable lifting mode to avoid secondary pollution.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Own tomato planting base in Xinjiang+Machinery processing line+15 ye

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu