1.This is a kind of spiral advancing extrusion.

2.There are whole stainless steel and inner stainless steel type.

3. It can make vegetable and fruit juice.

4.One outlet juice,one outlet fruit&vegetable pulp.

5.Processing material is vegetable&fruit which is crushed into not more than 2*2cm size.

6.We can supply you with different Filter screens according to your needs on the hole diameter.

Industrial Lemon / Orange / Citrus Squeezer Machine

- Processing:

-

Juice EXTRACTOR

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

None

- Showroom Location:

-

None

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Processing Types:

-

Fruit

- Power:

-

1.5kw

- Voltage:

-

220v/110v

- Weight:

-

100kg

- Dimension(L*W*H):

-

400*300*780mm

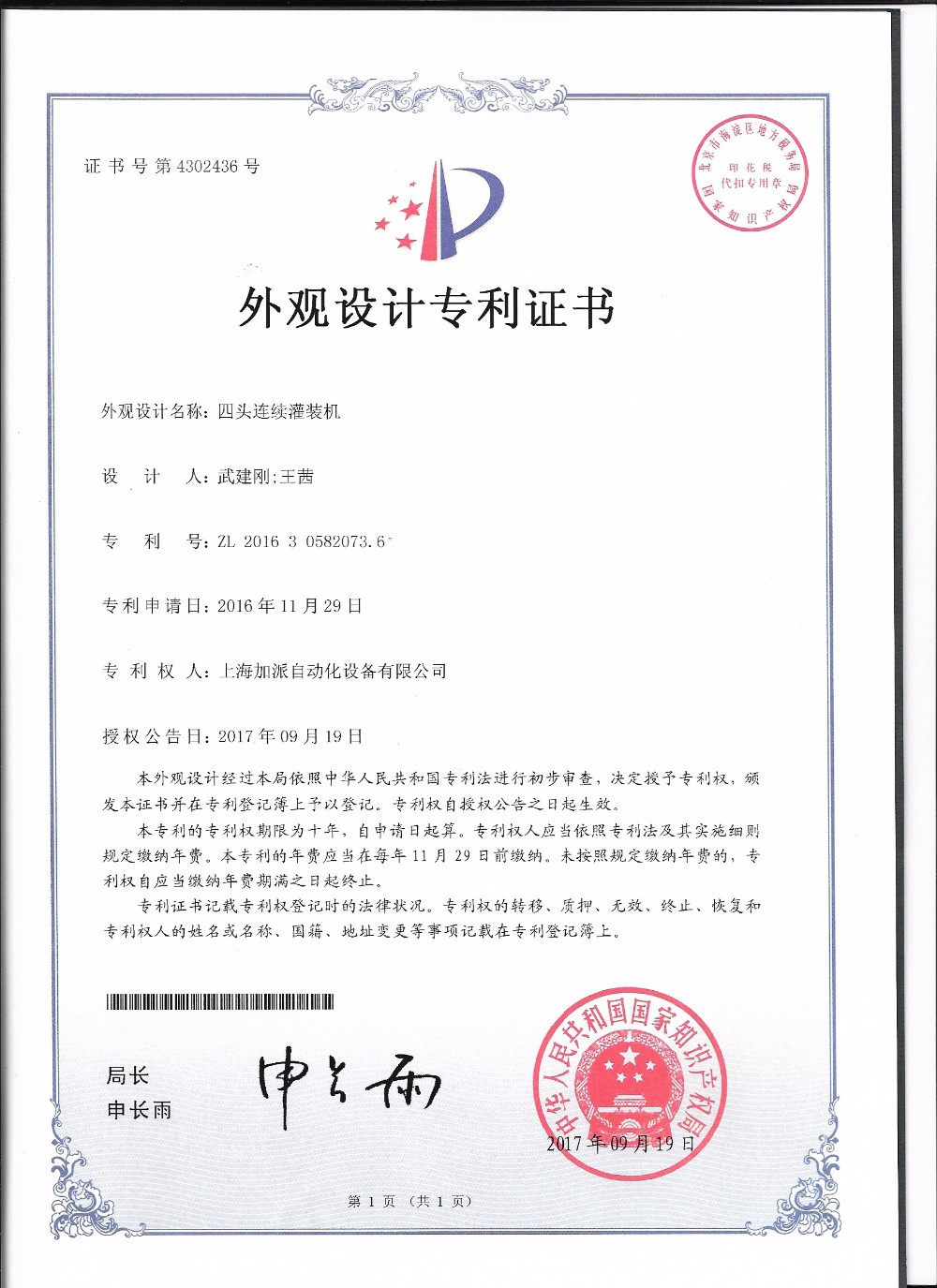

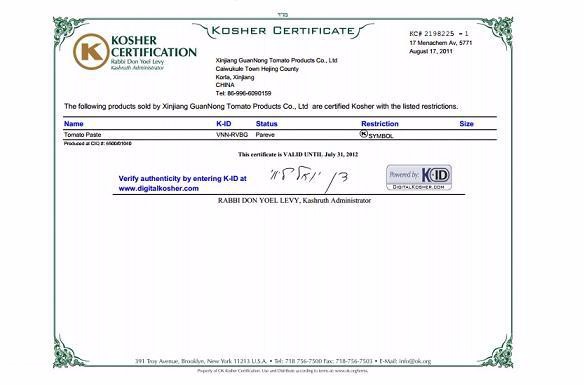

- Certification:

-

ISO

- Warranty:

-

One Year

- Marketing Type:

-

New Product 2020

- Machinery Test Report:

-

Provided

- Warranty of core components:

-

1 Year

- Core Components:

-

Motor

- Key Selling Points:

-

Sustainable

- Video outgoing-inspection:

-

Provided

- After-sales Service Provided:

-

Overseas service center available

- Product name:

-

Fruits juicer /extractor/squeezing machine

- Material:

-

Stainless Steel Body

- Name:

-

Juicer Machine

- Item:

-

Automatic Fruits Juicer Machine

- Usage:

-

Extracting Vegetables

- Application:

-

Beverage Fruit Store

- Type:

-

Screw Juicer

- Capacity:

-

300-1000kg/h

- Color:

-

Optional

- Supply Ability:

- 25 Set/Sets per Month industrial lemon squeezer

- Packaging Details

- package in wooden cartons

- Port

- shanghai

Spiral crushed juicer machine /screw juicer

Industrial commercial spiral juicer Super high-yield large-scale commercial juicer / extractor / squeezer.

It is used to squeeze fruits such as pineapple, apple, pear, etc.; it is used to crush berries such as mulberry, grapes, oranges, and oranges; it is used to crush tomatoes, ginger, garlic, celery and other vegetables.

1, juicer machine structure:

The utility model is composed of a front support, a feed hopper, a spiral, a filter net, a juicer, a rear support, a slag discharge tank and the like. The left end of the spiral main shaft is supported in the rolling bearing housing, and the right end is supported in the hand wheel bearing housing, and the electric motor passes through Work on the V-belt drive screw.

2, the working principle:

The main component of the device is a spiral. The diameter of the spiral gradually increases along the direction of the slag outlet and the pitch gradually decreases. When the material is propelled by the spiral, the volume of the spiral cavity is reduced to form a pressing of the material.

The direction of rotation of the spiral main shaft is seen from the direction of the hopper to the slag groove, which is the direction of the needle. The raw material is added to the feed hopper, pressed under the advancement of the spiral, and the pressed juice flows through the filter into the bottom of the juicer, and the waste is discharged through the gap formed between the spiral and the tapered portion of the pressure regulating head. The movement of the indenter in the axial direction adjusts the size of the gap. When the handwheel bearing seat is transported clockwise (from the slag tap of the equipment to the feed hopper), the pressure regulating head is turned to the left, and the gap is reduced, otherwise the gap becomes larger. Change the size of the gap, that is, adjust the resistance of the slag, you can change the juice rate, but if the gap is too small, under strong extrusion, some of the slag particles will be squeezed out through the filter together with the juice, although the juice increases, but The quality of the juice is relatively reduced, and the size of the void should be determined according to the specific process requirements of the user.

Fruits juicer /extractor/squeezing machine/Belt Juicer

Why choose us?

1.”Quality is priority”. we always attach great importance to quality control from the very beginning to the very end;

2.we have a professional manufacture experience and machining equipment;

3.we are factory ,we can provide you the super quality and very competitive price;

4.company has a quality,young,innovative and strong scientific research technical team

Is your price competitive?

surely we will give you best factory price based on superior product and service.

Any warranty?

1.one year equipment warranty after successful installation & commissioning of equipment and maintenance for lifelong time;

2.free installation and test before sending and free training for operation

3.advice for the solutions best for customers requirements

How about the test running & installation?

1.Before delivery, we finish the test over 3 times.

2.If you take integral design, no need to installation at all. If parted design, we can send our technicians to your place if necessary.

How to choose your wanted type?

1.tell us your requirement of the productivity.

2.You know about our machines ,the just tell us the type.

3.Give us the detailed information about your raw material,Picture will be best

Tomato paste production line

100% Response Rate

Filling machine

100% Response Rate

Milk processing line

100% Response Rate