Vegetable spray drying equipments for tomato powder,onion powder

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

N/A

- Model Number:

-

Customized

- Type:

-

vegetable powder making machine

- Voltage:

-

380V/220V

- Power:

-

4kw

- Weight:

-

80T

- Dimension(L*W*H):

-

1600*730*840mm

- Certification:

-

ISO CE

- Warranty:

-

12 Months

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

tomato powder making machine

- Production capacity:

-

3-500 T/D

- Material:

-

SUS 304 Stainless Steel

- Function:

-

complete processing line

- Usage:

-

tomato, onion, carrot, chili, garlic etc.

- Raw material:

-

fresh fruit

- Advantage:

-

turnkey solution

- Name:

-

tomato powder equipment

- Application:

-

Kinds

- Feature:

-

Low Energy Consumption

- 10 Set/Sets per Month tomato powder equipment

- Packaging Details

- standard export shipping standard.If you have your instruction,we will follow

- Port

- shanghai port

- Lead Time :

- 50-80days

Tomato powder equipment

Spray drying equipment and pressure-type centrifugal separation, depending on thematerial properties to choose different atomization. widely used in chemical, food, medicine and industry.

Centrifugal spray: apply to engage in viscosity or solid particles with the material, spraya wide operating flexibility. Production capacity can be designed to be adjusted within ± 25%.

Pressure spray tower: for low viscosity liquid materials and pure, high-pressure pump(8-20MPa), from a special nozzle.

Technical Note: The auxiliary equipment includes, air filters, air heater, dust separation equipment, knock powder devices, access devices and materials into the air exhaustdevice. High clean air filter can be used in effective fiber; run vacuum tower is 100-200Pamore reasonable; drying tower when the wind speed is less than 0.4 m / s, fine dust about80% of a smooth settlement, usually cyclone and filter using two net system recovery.Cyclone cylinder and the cone is not more than five times the total height of the cylinder diameter is appropriate.

Technical parameters

Project Parameters Model 5 25 50150200-2000

Controlled inlet temperature 140-350

Outlet temperature 80-90

Maximum moisture evaporation quantity is 25 50150200-2000

Centrifugal spray head gear in the form of traditional mechanical transmission of compressed air

Maximum speed of 25000 180,001,800,015,000 8000-15000

Spray plate diameter 50 120 120 150 180 240

Steam electric power steam + heat + electricity, fuel, gas, hot air furnace

Electric heating power of 9,367,299 maximum

Dimensions (L × W × H) 1 × 0.93 × 2.2 3 × 2.7 × 4.26 3.5 × 3.5 × 4.8 5.5 × 4 × 7 to determine the actual situation

Dry recycling ≥ 95

Shanghai JUMP GROUP Co., Ltd, is keeping leadership position in the tomato paste and concentrated apple juice processing line. We also have made brilliant achievements in other fruit& vegetable beverage equipments, such as:

1. Juice production line for orange juice, grape juice, jujube juice, coconut drink/coconut milk, pomegranate juice, watermelon juice, cranberry juice, peach juice, cantaloupe juice, papaya juice, sea buckthorn juice, orange juice, strawberry juice, mulberry juice, pineapple juice, kiwi juice, wolfberry juice, mango juice, sea buckthorn juice, exotic fruit juice, carrot juice, corn juice, guava juice, cranberry juice, blueberry juice, RRTJ, loquat juice and other juice drinks dilution filling production line

2. Can food production line for canned Peach, canned mushrooms, canned chili sauce, paste, canned arbutus, canned oranges, apples, canned pears, canned pineapple, canned green beans, canned bamboo shoots, canned cucumbers, canned carrots, canned tomato paste, canned cherries, canned cherry

3. Sauce production line for mango sauce, strawberry sauce, cranberry sauce, canned hawthorn sauce etc.

We grasped proficient technology and advanced biological enzyme technology, successfully applied in more than 120 domestic and foreign jam &juice production lines and we has helped client gain excellent products and good economic benefits.

Whatsapp/Line/Wechat/Mobile: 008618018520615 Welcome any inquiry!

Main Features

we take advantages of the comprehensive and technical cooperation with the Italian company partner, now in fruit processing, cold breaking processing, multi effect energy saving concentrated, sleeve type sterilization and aseptic big bag canning has made domestic and unmatched technical superiority. We can provide the entire production line processing 500KG-1500 tons of raw fruit daily according to the customers.

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of "Quality and Service Branding", after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

Whatsapp/Line/Wechat/Mobile: 008618018520615 Welcome any inquiry!

Spray cleaning machine

Material: SUS304 Stainless Steel with Stainless steel Scraper lifting,

Functions: receiving,washing,lifting

Motor Power: 3KW

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

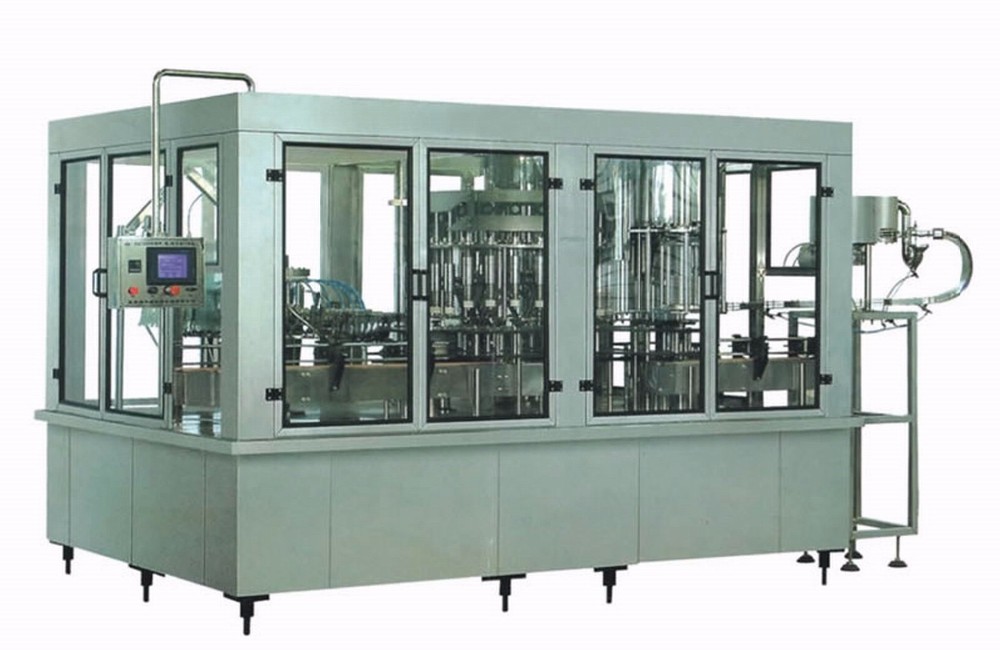

Filling maching

Specially suitable for tomato paste, mango puree and other viscous product.

35-50 bottle per min

Filling sachet valume:10-500g

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu