Pineapple Juice Extractor Juicer

Product Application

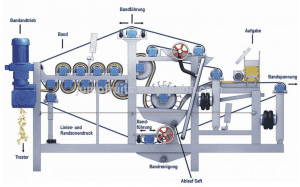

Automatic pineapple juice processing plant

This machine has washing ,filling and capping three functions in one body, total process is automatic, and it is suitable for high temperature resistant PET bottled juice and tea drink filling, it applies advanced micro-pressure gravity type filling principle, with perfect re-circulation system, without contacting with material, avoid secondary pollution and oxidation. It is made of high quality SUS304 stainless steel,the material of parts inside of the filling valve must be SUS316 . Main components are processed precisely by CNC machine tools. The machine adopts advanced photo electricity to detect running status. No bottle no filling. It is possible to realize man-machine conversation because of applying touch screen for operation.

Main Features

PET Bottle Fruit Juice Liquid Filling Machine—-Main performance

●Bottle is entered by air conveyor, the speed of bottle entering is fast and bottle shape is not changed because of adopting hanging clamping bottleneck way.

●Adopting clamping bottleneck way to wash bottle mouth and avoiding touch screw mouth, adopting clamping bottleneck way in the whole conveying process. When bottle type changes, you need to change the board related with bottle diameter.

●Filling adopts cylinder feeding structure, filling valve adopts high filling speed and mass flow rate valve which control liquids level accurately and without loss.

●The capping system applies advanced French technology, when clamp the cap will screw immediately and magnetic torque type capping head.

●Main PLC and frequency changer are used famous brand, such as Mitsubishi and Omron etc.

Washing Parts

It adopts rotary design, which mainly used for washing empty bottles of juice and water etc. Then transfer the clean bottles into filling part.

PET bottles entrance to equipments by star wheel, the bottles clamped and reversed to make the bottle down. Washing with sterilizing water and drain well, then turn over the bottle up automatically. Main structure and washing part are made by stainless steel, simple structure and easy adjustable; Less contact with bottleneck, which can avoid secondary pollution effectively.

Filling Part

This Filling Machine is design by XINMAO, Filling valve adopts negative filling way, filling fast and sensitive; the precision of filling liquid surface is high; There is no spring in valve, materials don’t contact with the spring directly, which is good for cleaning valve. To make sure the filling process and filling temperature, when there is no bottle or closed down, the materials in valve is under micro back flow condition. Whole machine are controlled by PLC automatically.

Packing & Delivery

Our Service

FAQ

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.

Certifications