Name: Tomato Powder

Brand: Jump

Original: China

Food grade SUS 304 machine,high quality

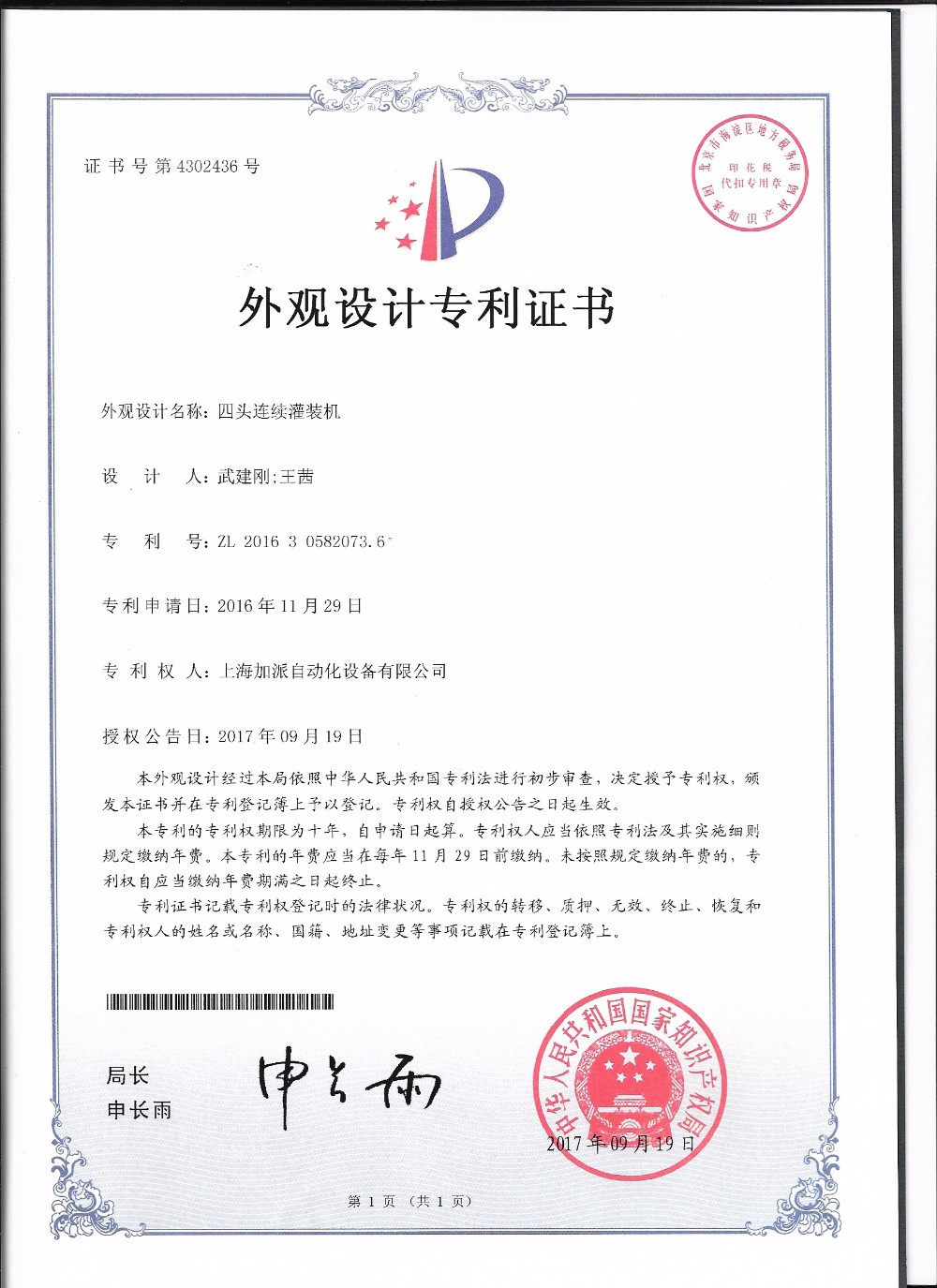

Shanghai JUMP Automatic Equipments Co., Ltd . is committed to providing the food processors, suppliers and other customers around the world with leading technology,

high-quality product, individual solution and superior service. After nearly 15 years' innovation and self-development, JUMP has been a leading supplier in China for complete plants of machinery and engineering Vegetables and fruit paste processing, juice drink processing and fruit powder processing and so on. The design,manufacture, installation, commissioning as well as the technical training and after sales are all handled by JUMP.

JUMP is devoted to absorbing the world advanced technology all the time. JUMP has already set up friendly technical and business cooperation with Chinese Academy of Agricultural Sciences 、Shanghai Academy of Agricultural Sciences 、Jiangnan University College of food engineering and so on.

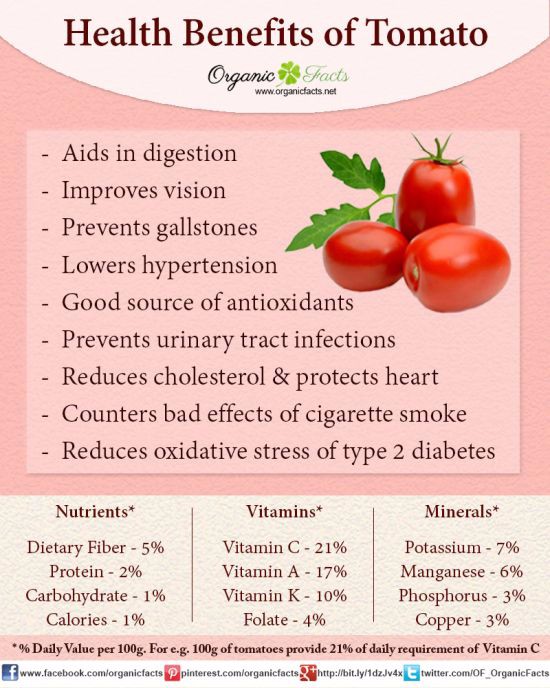

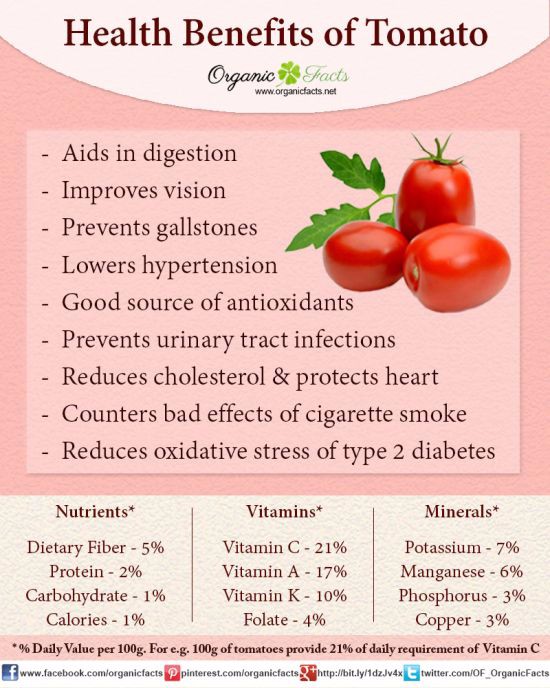

Tomato water content is quite high, about 95%, there are few other fruits and vegetables has such a high water content, therefore, packaging, transport and storage dry weight of 1 kg of tomatoes, 19 kg have to packaging, transport and storage of water.For consumers, every purchase dry weight of 1 kg of tomatoes, also have to bear the brunt of 19 kg water fee.If the processing tomato in tomato powder, can be a lot of saving the cost of packaging, transport, storage and consumption.Although tomato concentrate products such as tomato sauce has 3/4 or 3/4 above to remove moisture, but for per kg of dry weight of tomato, it still has a 2-3 kg of water.Also because concentrated tomato products solids content is higher, the consistency is also more and more big, therefore, the more to the back, that is very difficult to further reduce the water by evaporation, resulting in the waste heat, the product cost is increased.And tomato pulp concentration behind, because its contain ingredients such as cellulose, prone to JiaoGuo, concentrated time more long, the color and flavor greatly, seriously affect the quality of tomato concentrate products.In addition, the high solid content of tomato concentrate in the process of storage, especially at higher temperature region, easy to change the quality.Can be greatly reduced if the ketchup processed into tomato powder, packaging and sales cost, thus can offset the production cost of dry.

1.The whole line composition:

A: hydraulic flume → low-level elevating → washing → elevating and crushing → soaking → juicing → oven drying → forage

B: hydraulic flume → low-level elevating → washing → elevating and crushing → soaking → juicing → juicing → seperation filtration → evaporator → spray drying → fruit powder

Name: Tomato Powder

Brand: Jump

Original: China

Keep the tomato natural property, natural color and flavor, good liquidity;In machining process is easy to operate, spray evenly, to achieve consistency

|

Packaging

|

||

|

Size

|

123 (L) * 456 (W) * 789 (D)

|

|

|

Weight

|

1.2 T

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

|

Packaging

|

||

|

Size

|

123 (L) * 456 (W) * 789 (D)

|

|

|

Weight

|

1.2 T

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

100 % Response Rate

100 % Response Rate

100 % Response Rate