Manufacturing automatic orange juice concentrate juicer machine

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location:

-

Uzbekistan

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

1 Year

- Core Components:

-

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Type:

-

orange juice concentrate machine

- Voltage:

-

380V/50HZ

- Power:

-

2.2kw

- Weight:

-

40 tons

- Dimension(L*W*H):

-

depends on the capacity of the machine

- Certification:

-

CE/ISO9001

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

orange juice concentrate machine

- Function:

-

high Extracting

- Application:

-

fruit juice factory

- Item:

-

Automatic orange Juicer Machine

- Feature:

-

Easy Operation

- 10 Set/Sets per Week Orange juice concentrate machine

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- Shanghai port

Orange juice concentrate machine:

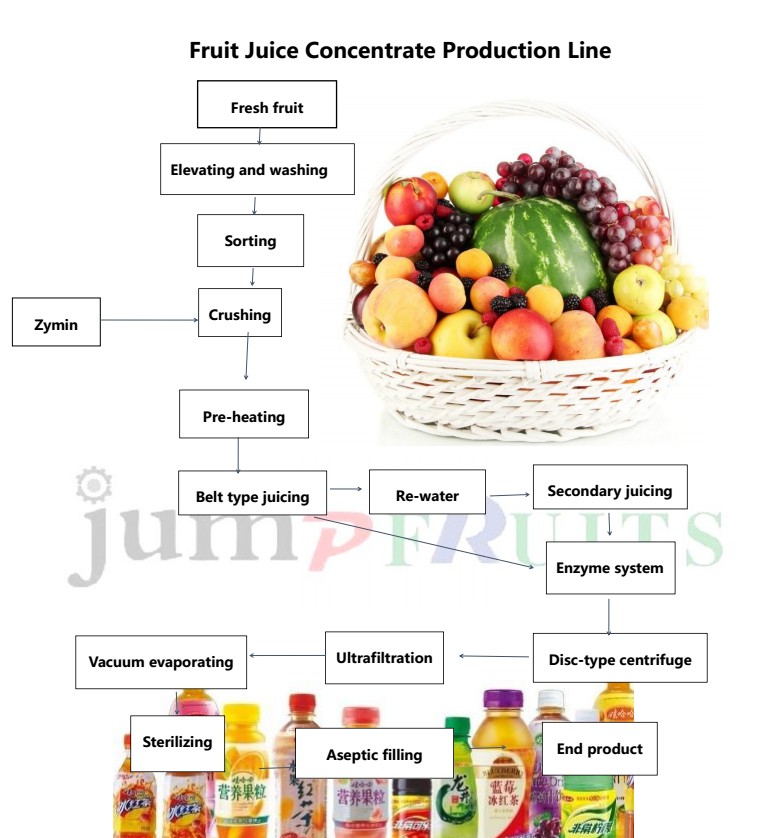

This orange juice concentrate making machine suits for navel orange, citrus, grapefruit, lemon processing line. The final fruit juice types can be clear juice, cloudy juice, juice concentrate and fermented beverages; It can also produce fruit powder. The production line consists of fruit washing machines, elevators, blanching machine, cut machine, crusher, pre-heater, beater, sterilization, filling machines, three-way four-stage evaporator and spray drying tower, juice filling and packaging machine etc. The orange juice production line adopts advanced design and high degree of automation. The main equipments are manufactured by high-quality stainless steel and in full compliance with food processing hygiene requirements.

Product Advantages:

Processing capacity : 3 tons to 1,500 tons / day.

* Raw Material: carrots, pumpkins,date,apple,orange,tomatoes

* Final product: clear juice, cloudy juice, juice concentrate and fermented beverages

* To prevent browning by blanching

* Aging the soft tissue to increase juice yield

* Can get different tastes by dilution.

* High degree of automation of the entire fruit juice processing line, without using a lot of manpower.

* With cleaning system, easy to clean.

* System Material contact parts are 304 stainless steel, in full compliance with food hygiene and safety requirements.

Main Features

we take advantages of the comprehensive and technical cooperation with the Italian company partner, now in fruit processing, cold breaking processing, multi effect energy saving concentrated, sleeve type sterilization and aseptic big bag canning has made domestic and unmatched technical superiority. We can provide the entire production line processing 500KG-1500 tons of raw fruit daily according to the customers.

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of "Quality and Service Branding", after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

The final Package of orange juice : glass bottle, PET plastic bottle, cans, aseptic soft package, roof pack 2L-220L sterile bag, carton package, plastic bag, 70-4500g tin can.

A. Orange jucie Scraper-type spray elevator

Select stainless steel bracket, food-grade and hard plastic or stainless steel scraper, smoothing blade architecture to prevent the fruit jam; Using imported anti-corrosion bearings, double-sided seal; with continuously variable transmission motor, variable frequency Speed and low operating costsTitle goes here.

B. Orange Sorting machine

Stainless steel roller conveyor, rotation and solution, a full range of check, no need ends. Manmade fruit platform, painted carbon steel bracket,stainless steel antiskid pedal,stainless steel fence.

C. Orange juicer machine

Fusing Italian technology, multiple sets of cross-blade structure, crusher size can be adjusted according to customer or specific project requirements, it will increase the juice juice rate of 2-3% relative to the traditional structure , which is suitable for production of onion sauce, carrot sauce, pepper sauce , apple sauce and other fruits and vegetables sauce and products

D. Orange juice Evaporator

Single-effect, double-effect,triple-effect and multi-effect evaporator, which will save more energy; Under vacuum, continuous low temperature cycle heating to maximize the protection of nutrients in the material as well as the originals. There are steam recovery system and double times condensate system, it can reduce the consumption of steam;

E. Orange juice Sterilization machine

Having obtained nine patented technology, take full advantages of the material's own heat exchange to save energy– about 40%

F. Orange juice Filling machine

Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return; Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ; In the filling process,using turntable lifting mode to avoid secondary pollution.

Shanghai JUMP Automatic Equipments Co., Ltd has independent intellectual property rights of the equipment include: large scale vacuum evaporation equipment(1000L-60000L/H),large sterilization equipment (tube and tube type 1T/H-50T/H), large drying equipment, aseptic filling equipment, and many different fruit advanced pre-treating equipment. The special evaporator for fruit juice and jam which has high performance, ultra low temperature , within the industry reputation; large tube sterilization equipment, a major breakthrough in energy saving, and industry with equipment compared to energy saving is about 30%, won the national patent (Patent No.: ZL 20112 56107.2 tomato sauce; aseptic filling machine won the 2017 annual China fruit and vegetable processing equipment quality brand products (NO:CFPMA-2017-0502), various types of advanced cleaning machine, crushing machine, spiral juicer and belt juicer, nearly 10 years of quality and sales volume in the forefront of the industry.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Why choose us?

1."Quality is priority”. we always attach great importance to quality control from the very beginning to the very end;

2.we have a professional manufacture experience and machining equipment;

3.we are factory ,we can provide you the super quality and very competitive price;

4.company has a quality,young,innovative and strong scientific research technical team

Is your price competitive?

surely we will give you best factory price based on superior product and service.

Any warranty?

1.one year equipment warranty after successful installation & commissioning of equipment and maintenance for lifelong time;

2.free installation and test before sending and free training for operation

3.advice for the solutions best for customers requirements

How about the test running & installation?

1.Before delivery, we finish the test over 3 times.

2.If you take integral design, no need to installation at all. If parted design, we can send our technicians to your place if necessary.

How to choose your wanted type?

1.tell us your requir

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu