Machinery Equipment For Producing Peanut Butter

- Place of Origin:

-

Shanghai, China

- Voltage:

-

220V/380V

- Certification:

-

ISO-9001, QS

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Field installation, commissioning and training

- Application fields:

-

Snack food factory, Flour mill, Bakery, Vegetable processing plant, Seasoning plant, Frozen food Factory

- Machinery Function:

-

grinding

- Raw material:

-

Corn, Wheat, Nuts, Flour, Soybean

- Output product name:

-

peanut butter

- Product name:

-

peanut butter making machine

- Material:

-

Stainless Steel 304

- Usage:

-

Industrial Usage

- Capacity:

-

1-50 t/h

- Application:

-

Food paste processing plant

- Item:

-

industrial fruit vegetable puree machine

- Name:

-

fruit puree making machine

- Color:

-

silver or customer’s requirements

- Function:

-

from washing to butter packing

- Feature:

-

Turn Key Project

- Supply Ability:

- 20 Set/Sets per Month peanut paste making machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- Shanghai

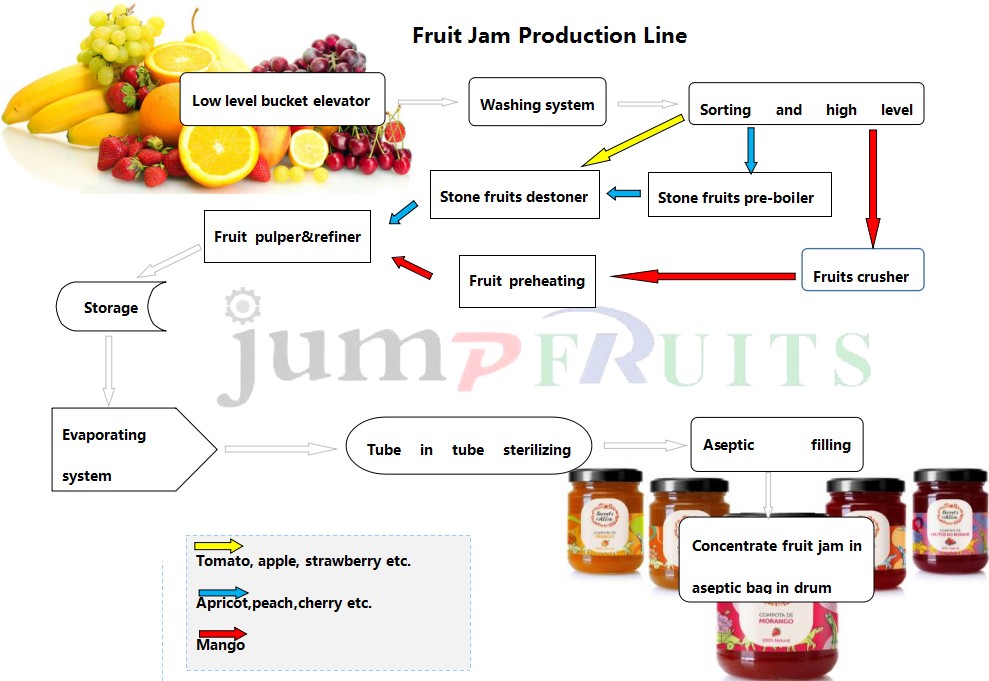

2.The whole line composition:

A: promotion system of the original fruits, cleaning system, sorting system, crushing system, pre-heating sterilization system, pulping system, vacuum concentration system, sterilization system, aseptic bag filling system

B: pump → blending drum → homogenization →deaerating → sterilization machine → washing machine → filling machine → capping machine → tunnel spray sterilizer → dryer → coding → boxing

Our Advantages:

1.Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop services, from your warehouse designing(water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

2.15 years export experience, easily transport cargo to your door

3.customized service, we will try our best to meet your requirement.

4.Quality guarantee: 12 months. After that, engineers also available on your traval expense and spare parts cost.We offer life-long after-sale service.

Main advantages of our system line:

1. High production speed achieved by a newly designed head system (single head or twin heads available), improved reliability from a fully PLC controlled self diagnostic operational mode.

2. Greater versatility by meeting various packing standards with different products.

3 Coordinates well with the tube in tube sterilizer, if some malfunction with the filler, the product will be automatic flow back into the buffer tank before the UHT sterilizer.

4. The use of a hermetically sealed empty bag ensures the bag will remain sterile before it is filled.

5. High pressure saturated steam is used for sterilization of the fitment, cap and exposed portion of the filler prior to each filling cycle. NO CHEMICALS are required.

6. The sealing of the fill valve on the interior of the fitment keeps product completely away from the package sealing area.

7. The hermetic heat sealing of the fitment provides a tamper evident closure and a superior oxygen barrier.

8. The overall aseptic design of the filler allows uninterrupted. Operation throughout a complete tomato/fruit season, maximizing your plant’s efficiency

9. CIP and SIP available together with tube in tube sterilizer

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.