Industrial Automatic matcha green tea powder production line machine

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JPF-MCF001

- Type:

-

matcha production line

- Voltage:

-

380V/50HZ

- Power:

-

200 kw

- Weight:

-

20TONS

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

ISO 9001,CE

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

matcha powder production line

- Material:

-

304 Stainless Steel

- Name:

-

matcha powder Making Machine

- Application:

-

Root Vegetables

- Function:

-

grinding, baking, milling, filling,packaging

- Capacity:

-

0.5-5t/h

- Item:

-

Automatic matcha powder Making Machine

- Feature:

-

turn key solution

- Color:

-

Customers' Requirements

- 3 Set/Sets per Month tea bag pakaging machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- shanghai

- Lead Time :

- 60-90 days

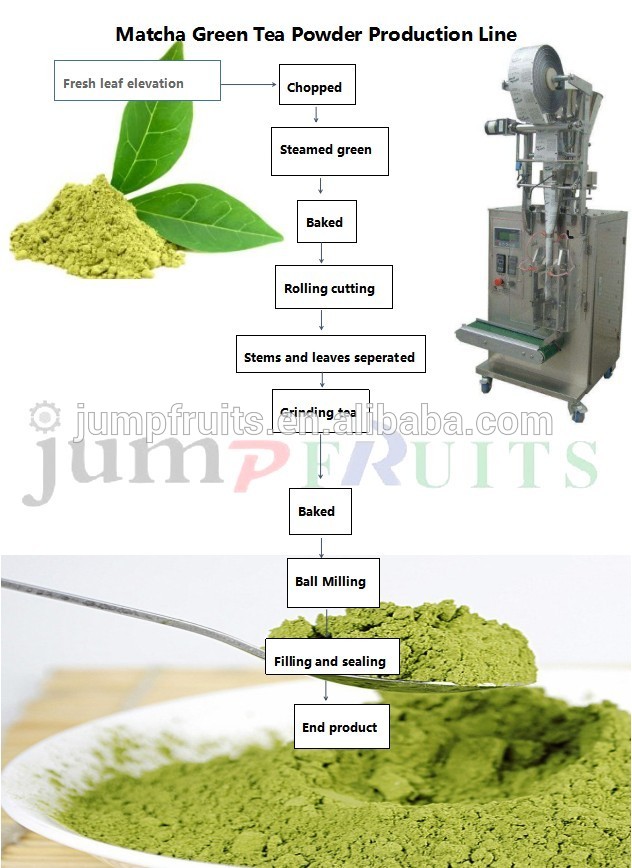

2.The whole line composition:

Fresh leaves raised→ chopped→steamed green→baked→ rolled cutting→stems and leaves separated→ grinding tea→baking→ ball milling→filling→sealing→ finished product.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Why choose us?

1."Quality is priority”. we always attach great importance to quality control from the very beginning to the very end;

2.we have a professional manufacture experience and machining equipment;

3.we are factory ,we can provide you the super quality and very competitive price;

4.company has a quality,young,innovative and strong scientific research technical team

5. Is your price competitive? surely we will give you best factory price based on superior product and service.

Any warranty?

1.one year equipment warranty after successful installation & commissioning of equipment and maintenance for lifelong time;

2.free installation and test before sending and free training for operation

3.advice for the solutions best for customers requirements

How about the test running & installation?

1.Before delivery, we finish the test over 3 times.

2.If you take integral design, no need to installation at all. If parted design, we can send our technicians to your place if necessary.

How to choose your wanted type?

1.tell us your requirement of the productivity.

2.You know about our machines ,the just tell us the type.

3.Give us the detailed information about your raw material,Picture will be best