High proficiency tomato concentrate paste processing line

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

one-stop service

- Type:

-

complete plan for a food engineering project

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

N/A

- Dimension(L*W*H):

-

N/A

- Certification:

-

CE/ISO9001

- Warranty:

-

1 Year warranty,life-long aftersell service

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

tomato ketchup line

- Application:

-

building food&beverage plant

- Name:

-

customized complete processing line

- Feature:

-

turnkey solution

- Capacity:

-

200kg/h to 100T/H treatment capacity as customer require

- Function:

-

Shreding

- Material:

-

Food Grade Stainless Steel

- Usage:

-

Commercial Fruit Peeling Machine Usage

- Item:

-

Industrial Fruit Pulp Machine

- Color:

-

Demands

- 20 Set/Sets per Year tomato ketchup line

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- shanghai port

- Lead Time :

- 2-3 months

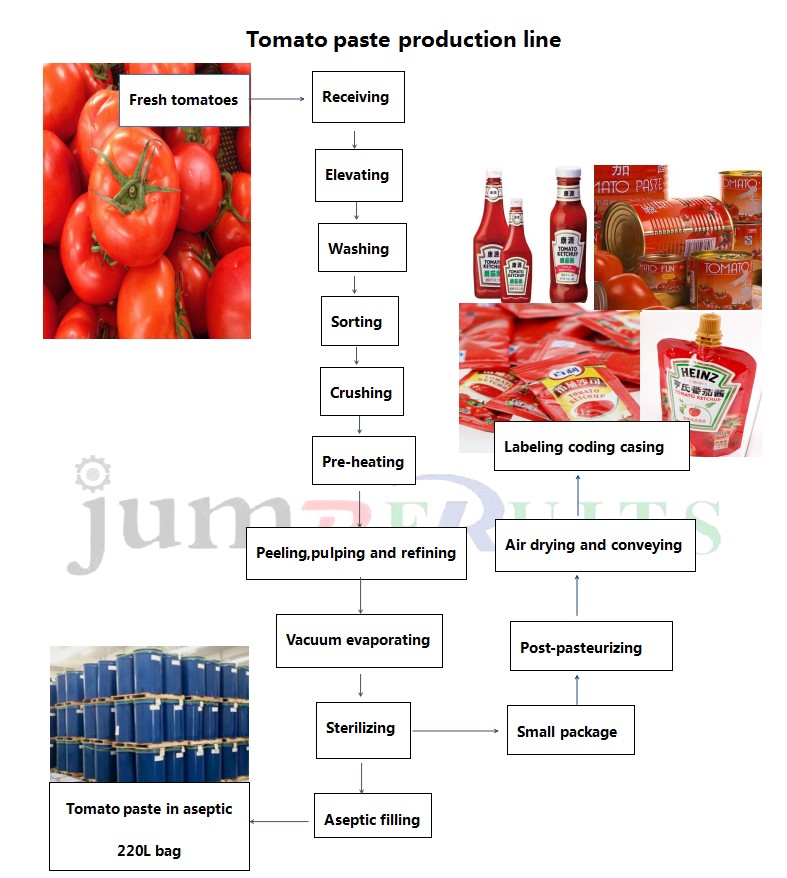

Tomato paste production line

Our unique–Turnkey Solution.:

No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Consulting + Conception

As a first step and prior to project implementation, we will provide to you profoundly experienced and highly competent consulting services. Based on an extensive and thorough analysis of your actual situation and requirements we will develop your customized solution(s). In our understanding, customer-focused consultation means that all steps planned – from the initial conception phase to the final phase of implementation – will be conducted in a transparent and comprehensible manner.

Project Planning

A professional project planning approach is a prerequisite for the realization of complex automation projects. On the basis of each individual assignment we calculate time frames and resources, and define milestones and objectives. Due to our close contact and cooperation with you, in all project phases, this goal-oriented planning ensures the successful realization of your investment project.

Design + Engineering

Our specialists in the fields of mechatronics, control engineering, programming, and software development closely cooperate in the development phase. With the support of professional development tools , these jointly developed conceptions will then be translated into design and work plans.

Production + Assembly

In the production phase, our experienced engineers will implement our innovative ideas in turn-key plants. The close coordination between our project managers and our assembly teams ensures efficient and high-quality production results. After the successful completion of the test phase, the plant will be handed over to you.

Integration + Commissioning

In order to reduce any interference with associated production areas and processes to a minimum, and to guarantee a smooth set-up, the installation of your plant will be conducted by the engineers and service technicians who have been assigned to and accompanied the individual project development and production stages. Our experienced staff will ensure that all required interfaces work, and your plant will be successfully put into operation.

Tomato washing machine

Tomatoes are washed by high pressure water in the fruit washing machine. Scraper elevator conveys the cleaned tomatoes to the next procedure.

Roller sorting machine

Cleaned fruits enter into the machine from the feeding hopper, and rotate forward toward the outlet. Workers pick out the unqualified tomatoes to ensure the quality of the end product.

Broken Pump

Used for conveying and crushing of tomatos, preparing for pre-heating and pulping.

Tubular Preheater

Tubular preheater increases the temperature of the pulp by steam heating, so that to soften the pulp and deactivate the enzymes.

Single-channel Pulping Machine

Single-channel pulping machine is used for automatic separation of pulp and residue from the crushed and preheated tomatoes. The material from the last procedure enters into the machine through the feed inlet, and spirals toward the outlet along the cylinder. By centrifugal force, the material is pulped. The pulp passes through the sieve and is sent to the next procedure, while the skin and seeds are discharged through the residue outlet, achieving the aim of automatic separation. The pulping speed can be changed by changing the sieve and adjusting the lead angle of the scraper.

Vacuum Evaporator

This equipment is used for vacuum concentration of tomato pulp under low temperature. Steam is fed into the jacket at the lower part of the boiler, making the material under vacuum boil and evaporate. Blender in the boiler helps strengthen the flowing of the material.

Tubular Sterilizer

Tubular sterilizer increases the temperature of the concentrate by steam heating, achieving the aim of sterilization.

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Tomato paste filling sealing and packaging machine

Specially suitable for tomato paste, mango puree and other viscous product.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu