High Proficiency Blueberry Wine Processing / Fruit Wine Production Line

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JPF-GJ7824

- Type:

-

complete plan for a food engineering project

- Voltage:

-

Customized

- Power:

-

3kw

- Weight:

-

600kg

- Dimension(L*W*H):

-

1560*450*1340mm

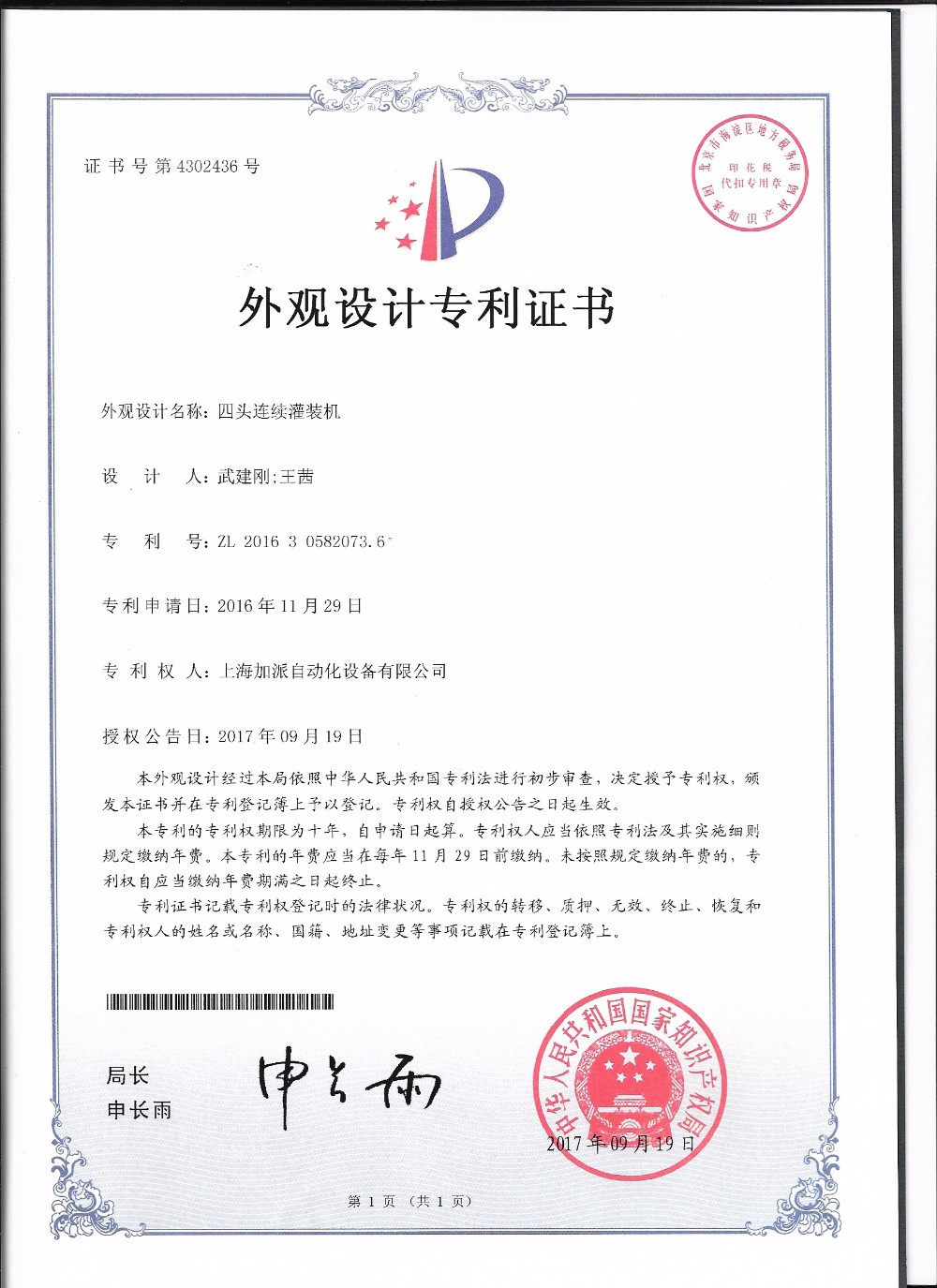

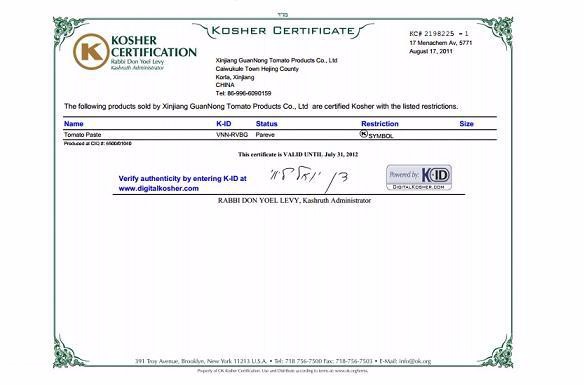

- Certification:

-

CE/ISO9001

- Warranty:

-

1 Year warranty,life-long aftersell service

- Capacity:

-

100kg/h to 100T/H treatment capacity as customer require

- Item:

-

Automatic Fruits Wine Machine

- Material:

-

304 Stainless Steel

- Packaging Details

- Stable wooden package protects machine from strike and damage.

- Port

- shanghai port

- Lead Time :

- 2-3 months

high proficiency blueberry wine processing/fruit wine production line

Fresh fruit → selection → crushing → except peduncle → fruit pulp → juice clarification → separation → juice → fermentation → wine storage → inverted bucket → filtering → cold treatment → mixing → filtering → product

Air Blowing & Washing Machine

1 Used to wash fresh tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

Peeling, pulping & Refining Monobloc (Pulper)

1. The unit can peel, pulp and refine fruits together.

2. The aperture of strainer screen can be adjustable (change) based on customer’s requirement.

3. Incorporated Italian technology, high quality stainless steel material in contact with fruit material.

Belt press extractor

1. Widely used in extracting and dehydrating of many kinds of acinus, pip fruits, and vegetables.

2. the unit adopt advanced technology, big press and high efficiency, high degree of automatic, easy to operate and maintains.

3. the extraction rate can be get 75-85%(based on raw material)

4. low investment and high efficiency

Preheater

1. To inactivate enzyme and protect color of paste.

2. Auto temperature control and the out temperature are adjustable.

3. Multi-tubular structure with end cover

4. If the effect of preheat and extinguish enzyme failed or not enough, the product flow return to tube again automatically.

Evaporator

1. Adjustable and controllable direct contact heat treatment units.

2. Shortest possible residence time, presence of a thin film along the entire length of the tubes reduces holdup and residence time.

3. Special design of liquid distribution systems to ensure correct tube coverage. The feed enters at the top of the calandria where a distributor ensures film formation on the inside surface of each tube.

4. The vapor flow is co-current to the liquid and the vapor drag improves the heat transfer. The vapor and the remaining liquid are separated in a cyclone separator.

5. Efficient design of separators.

6. Multiple effect arrangement provides steam economy.

Tube in tube sterilizer

1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

2. Incorporated Italian technology and conform to Euro-standard

3. Great heat exchange area, low energy consumption and easy maintenance

4. Adopt mirror welding tech and keep the smooth pipe joint

5. Auto backtrack if not enough sterilization

6. CIP and auto SIP available together with aseptic filler

7. Liquid level and temp controlled on real time

Pre-sales service

We can suggest customer the most suitable machine according to their formula and Raw material. “Design and development”, “manufacturing”, “installation and commiss