FM Series Laying Vertical Cooling Milk Tank Pot

- Applicable Industries:

-

Food & Beverage Factory

- Condition:

-

New

- Place of Origin:

-

China

- Brand Name:

-

Jumpfruits

- Voltage:

-

380v

- Power:

-

750w

- Weight:

-

510KG

- Dimension(L*W*H):

-

500*1060*1360MM

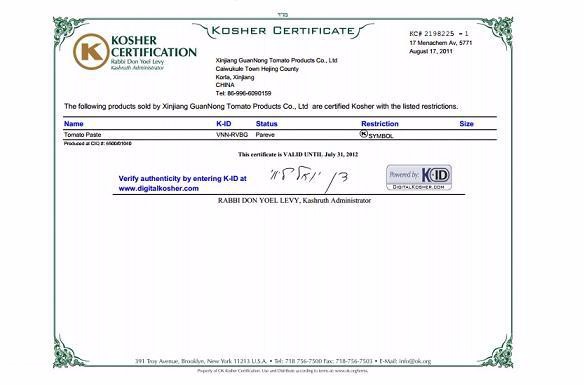

- Certification:

-

iso

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Field installation, commissioning and training

- Product name:

-

industrial milk cooling tank

- Material:

-

Food garde 304 Stainless Steel

- Function:

-

mixing tank ,cooling tank, storage tank

- Usage:

-

milk plant

- Name:

-

milk processing machine

- Item:

-

milk cooling tanks

- Color:

-

Silvery

- Capacity:

-

500kg/h

- Feature:

-

High Effiect

- Supply Ability:

- 3 Set/Sets per Month milk cooling tank

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- shanghai

FM series laying vertical cooling milk tank pot for milk processing plant

1. The tank wall use advanced dimple pad as evaporator exchange the heat directly with the milk inside.

2. The refrigeration compressor is imported from France, which composed of full closed compressor and imported expanding value and electromagnetism valve. The system has reliable midpoint protection device to protect the compressor being burned resulted from the overloading or system trouble.

3. All of SUS 304 or 316L stainless steel, with CIp, cleaning ball and Auto-stirring system.

4. With high insulation by PU.

Applications:

Mainly used for cool and storage for fresh milk, also can be used to cooling or storage for other liquid product. The cooling tank is the key equipment for the mechanical milking system in the dairy farms. Also widely used in the manual milking farm and milk collection centers, and milk production plants, which can keep the fresh milk at best state and prevent the bacterial growing.

Milk a full set of equipment:

Storage tanks – - – the milk tank – hot and cold beverage pump cylinder cream separator – to take off the angry machine – mixing cylinder – homogenizer – ultra high temperature sterilization machine – plate heat exchanger – seed tank fermentation tank – sterilization machine, automatic filling machine.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.