Customized Guava Juice Making Machine / Carrot Juicer / Banana Juice Machinery

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

OEM/JUMPFRUITS

- Model Number:

-

JPF-GZ4865

- Type:

-

PROCESSING LINE

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

60 TONS

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

ISO 9001,CE

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

- Material:

-

304 Stainless Steel

- Application:

-

Root Vegetables

- Function:

-

Multifunctional

- Capacity:

-

3-5t/h

- Item:

-

Automatic Fruits Juicer Machine

- Feature:

-

High Efficiency

- Supply Ability:

- 3 Set/Sets per Month

- Packaging Details

- carton box

- Port

- shanghai

- Lead Time :

- 50 days

Guava Juice Making Machine / Carrot Juicer / Banana Juice Machinery

Our Advantages:

1.Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop services, from your warehouse designing(water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

2.15 years export experience, easily transport cargo to your door

3.customized service, we will try our best to meet your requirement.

4.Quality guarantee: 12 months. After that, engineers also available on your traval expense and spare parts cost.We offer life-long after-sale service.

Main advantages of our system line:

1. High production speed achieved by a newly designed head system (single head or twin heads available), improved reliability from a fully PLC controlled self diagnostic operational mode.

2. Greater versatility by meeting various packing standards with different products.

3 Coordinates well with the tube in tube sterilizer, if some malfunction with the filler, the product will be automatic flow back into the buffer tank before the UHT sterilizer.

4. The use of a hermetically sealed empty bag ensures the bag will remain sterile before it is filled.

5. High pressure saturated steam is used for sterilization of the fitment, cap and exposed portion of the filler prior to each filling cycle. NO CHEMICALS are required.

6. The sealing of the fill valve on the interior of the fitment keeps product completely away from the package sealing area.

7. The hermetic heat sealing of the fitment provides a tamper evident closure and a superior oxygen barrier.

8. The overall aseptic design of the filler allows uninterrupted. Operation throughout a complete tomato/fruit season, maximizing your plant’s efficiency

9. CIP and SIP available together with tube in tube sterilizer

Guava Juice Making Machine / Carrot Juicer / Banana Juice Machinery

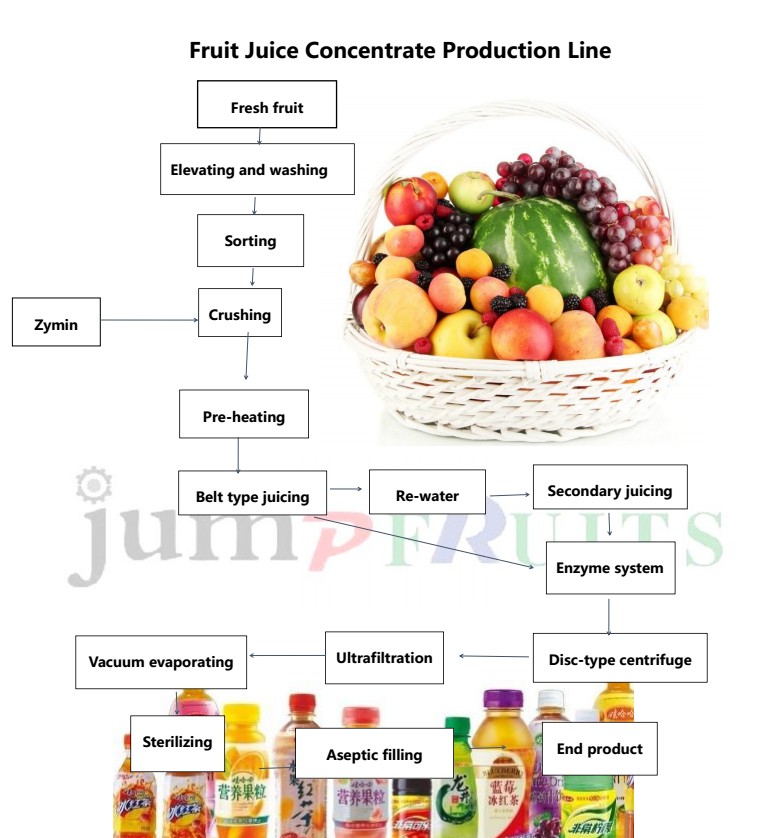

This line is suitable for processing tropical fruits such as mango, pineapple, papaya, guava and so on. It can produce clear juice, turbid juice, concentrated juice and jam. This line include bubble cleaning machine, hoist, selection machine, brush cleaning machine,cutting machine, precooking machine, peeling and denudation machine, crusher, belt juicer, separator, concentration equipment, sterilizer and filling machine, etc..This production line is designed with advanced concept and high degree of automation; The main equipment is all made of high-quality stainless steel, which fully meets the hygienic requirements of food processing. This production line design concept advanced, high degree of automation; The main equipment is all made of high-quality stainless steel, which fully meets the hygienic requirements of food processing.

* Capacity from 3 t / d to 1500 t / d.

* Can process similar characteristics of fruit, such as mango, pineapple, etc.

* Can be cleaned by multistage bubbling and brush cleaning

* Belt juicer can increase pineapple juice extraction rate

* Peeling,denudation and pulping machine to complete the juice collection of mango.

* Low temperature vacuum concentration, ensure flavor and nutrients, and greatly save energy.

* tube sterilization and aseptic filling to ensure the aseptic state of the product.

* with an automatic CIP cleaning system.

* The system material is all made of 304 stainless steel, which fully meets the requirements of food hygiene and safety.

Whatsapp/Line/Wechat/Mobile: 008613681836263 Welcome any inquiry!

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from yourwarehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of “Quality and Service Branding”, after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

A. Scraper-type spray elevator

Select stainless steel bracket, food-grade and hard plastic or stainless steel scraper, smoothing blade architecture to prevent the fruit jam; Using imported anti-corrosion bearings, double-sided seal; with continuously variable transmission motor, variable frequency Speed and low operating costsTitle goes here.

B. Sorting machine

Stainless steel roller conveyor, rotation and solution, a full range of check, no need ends. Manmade fruit platform, painted carbon steel bracket,stainless steel antiskid pedal,stainless steel fence.

C. Crusher

Fusing Italian technology, multiple sets of cross-blade structure, crusher size can be adjusted according to customer or specific project requirements, it will increase the juice juice rate of 2-3% relative to the traditional structure , which is suitable for production of onion sauce, carrot sauce, pepper sauce , apple sauce and other fruits and vegetables sauce and products

D. Double-stage pulping machine

It have tapered mesh structure and the gap with load can be adjusted, frequency control, so that the juice will be cleaner; Internal mesh aperture are based on customer or specific project requirements to order

E. Evaporator

Single-effect, double-effect,triple-effect and multi-effect evaporator, which will save more energy; Under vacuum, continuous low temperature cycle heating to maximize the protection of nutrients in the material as well as the originals. There are steam recovery system and double times condensate system, it can reduce the consumption of steam;

F. Sterilization machine

Having obtained nine ed technology, take full advantages of the material’s own heat exchange to save energy– about 40%

F. Filling machine

Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return; Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ; In the filling process,using turntable lifting mode to avoid secondary pollution.