Automatic Industrial Organic Apple Juice Concentrate Making Machine

- Raw material:

-

Fruit, Vegetables, Soybean

- Model Number:

-

GZL3TH

- Brand Name:

-

Jumpfruits

- Place of Origin:

-

China

- Voltage:

-

380v

- Power:

-

210KW

- Weight:

-

40T

- Certification:

-

ISO

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Field installation, commissioning and training

- Application fields:

-

Snack food factory, Fruit processing plant, Vegetable processing plant, Cannery, Beverage Factory, Seasoning plant

- Machinery Function:

-

Cleaning, juicer, filling

- Function:

-

apple juice production line

- Usage:

-

kinds of fruit juice processing machine

- Product name:

-

apple juice press machine

- Feature:

-

Multifunctional Fruit

- Key words:

-

Mango Pulp Extracting Machine

- Advantage:

-

Juicer Processing Machine

- Processing Types:

-

Fresh-Squeezed

- Capacity:

-

0.5~10t/h

- Supply Ability:

- 8 Set/Sets per Month apple juice production line

- Packaging Details

- standard export package, wrapped by plastic film and in wooden case

- Port

- Shanghai

- Lead Time :

-

Quantity(Sets) 1 – 1 >1 Est. Time(days) 60 To be negotiated

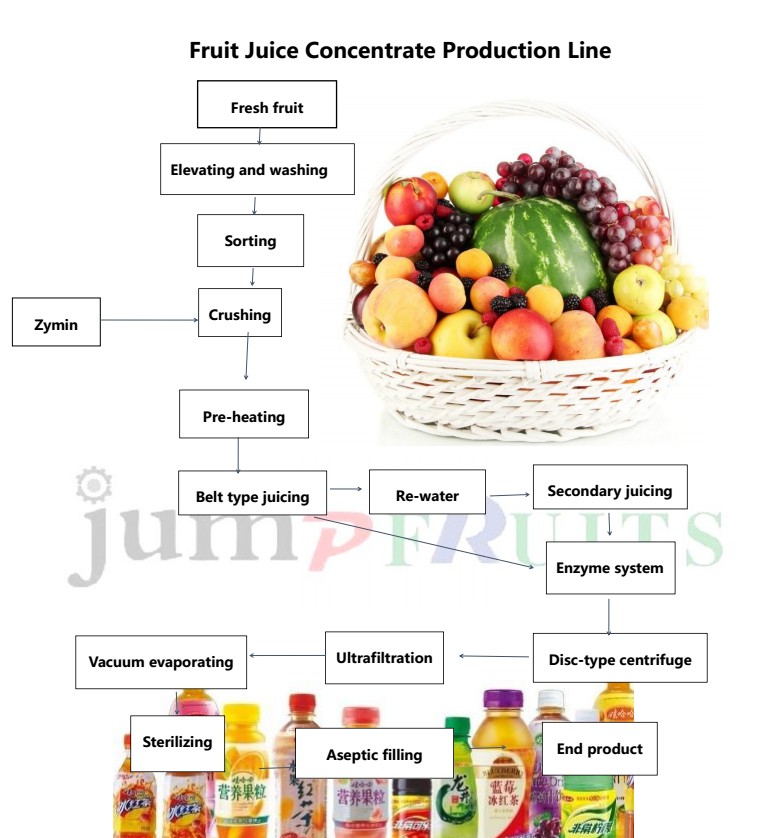

Apple juice concentrate production line

Our Advantages:

1.Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop services, from your warehouse designing(water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

2.15 years export experience, easily transport cargo to your door

3.customized service, we will try our best to meet your requirement.

4.Quality guarantee: 12 months. After that, engineers also available on your traval expense and spare parts cost.We offer life-long after-sale service.

JUMP is keeping leadership position in the tomato paste and concentrated apple juice processing line. We also have made brilliant achievements in other fruit& vegetable beverage equipments, such as:

Fresh apples Spray cleaning machine

Main characteristic:

1 Used to wash fresh tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

Motor Power: 3KW

Apple juice homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

Citrus Extractor

Main characteristic:

1. Stainless steel construction on all contact surfaces, a totally enclosed stainless steel construction on all contact surfaces, a totally enclosed stainless steel piping system to transport the juice to stainless steel finishers.

2. Citrus extraction system is unique in that is simultaneously recovers oil as well as juice during the same extraction cycle.

3. Bitter constituents such as cores, membranes, seeds, etc., are instantaneously separated from the juice and juice cells by the pre-finisher tube during the extraction cycle.

4. This outstanding performance is made possible due to the ability of the Citrus Extractor to squeeze citrus fruit efficiently at wide range of size and shape.

5. Handle most of the world’s citrus varieties and sizes. This minimizes the number of extractors required, resulting in space savings and reduced equipment costs.

6. Water usage and waste disposal are minimized through the use of water recycle systems.