Autoclave UHT Milk Sterilizer Machine Steam Sterilizer

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JP-CL1122

- Type:

-

heating

- Voltage:

-

220V/380V

- Power:

-

2.2kw

- Weight:

-

400kg

- Dimension(L*W*H):

-

2100*1460*1590mm

- Certification:

-

CE/ISO9001

- Warranty:

-

1 Year warranty,life-long aftersell service

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Usage:

-

to sterilizing and cooling of concentrate products

- material:

-

SUS 304

- Capacity:

-

5T-100T/H

- application:

-

to strawberry,banana,hawkthorn,apricot,tomato etc.

- Name:

-

pulping machine

- Function:

-

Remove

- Application:

-

Root Vegetables

- Product name:

-

pasteurizer

- Material:

-

304 Stainless Steel

- Item:

-

Automatic Fruits Juicer Machine

- Supply Ability:

- 20 Set/Sets per Month uht milk sterilizer machine

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- shanghai port

- Lead Time :

- 40 days

Pasteurizer

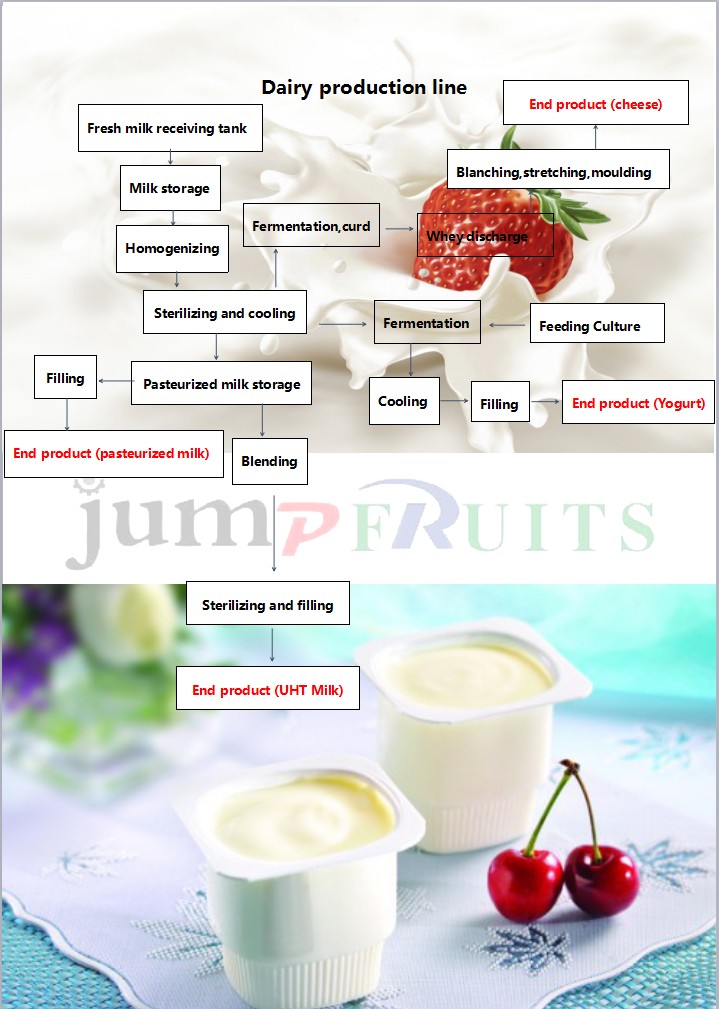

General flow chart:

process 1: Milk collection system

process 2: sterilization system

process 3: Storage system

process 4: filling system

process 5: water treatment and cleaning system

process 6: Steam boiler system

Introduction:

Pasteurized milk is one of the important process of processing, will extend the shelf life of milk.

Pasteurization temperature and time are very important factors must follow quality and shelf life of milk required for such precise requirements. Homogeneous, high-temperature short-time pasteurization temperature is usually 72-75 ℃, holding time of 15-20 seconds. Heat treatment required to kill undesirable microorganisms and must ensure that pathogens such products are not damaged.

Homogeneous object or to split the fat globules of fat globules in milk in a finely distributed state, and prevent the formation of cream layer. Can be all homogeneous, it can be partial. Partial homogenization method is very economical because you can use a small homogenizer.

Advantages:

1. Users can design special requirements

2. In the same production line can produce different end products

3. A short incubation time

4. Can be accurately added and mixed aromatic substances

5. high Yield, low loss

6. Application of high technology to save energy 20%

7. The entire production process monitoring systems

8. Image, intuitive display, print all process parameters

Our unique–Turnkey Solution.:

No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Consulting + Conception

As a first step and prior to project implementation, we will provide to you profoundly experienced and highly competent consulting services. Based on an extensive and thorough analysis of your actual situation and requirements we will develop your customized solution(s). In our understanding, customer-focused consultation means that all steps planned – from the initial conception phase to the final phase of implementation – will be conducted in a transparent and comprehensible manner.

Project Planning

A professional project planning approach is a prerequisite for the realization of complex automation projects. On the basis of each individual assignment we calculate time frames and resources, and define milestones and objectives. Due to our close contact and cooperation with you, in all project phases, this goal-oriented planning ensures the successful realization of your investment project.

Design + Engineering

Our specialists in the fields of mechatronics, control engineering, programming, and software development closely cooperate in the development phase. With the support of professional development tools , these jointly developed conceptions will then be translated into design and work plans.

Production + Assembly

In the production phase, our experienced engineers will implement our innovative ideas in turn-key plants. The close coordination between our project managers and our assembly teams ensures efficient and high-quality production results. After the successful completion of the test phase, the plant will be handed over to you.

Integration + Commissioning

In order to reduce any interference with associated production areas and processes to a minimum, and to guarantee a smooth set-up, the installation of your plant will be conducted by the engineers and service technicians who have been assigned to and accompanied the individual project development and production stages. Our experienced staff will ensure that all required interfaces work, and your plant will be successfully put into operation.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.