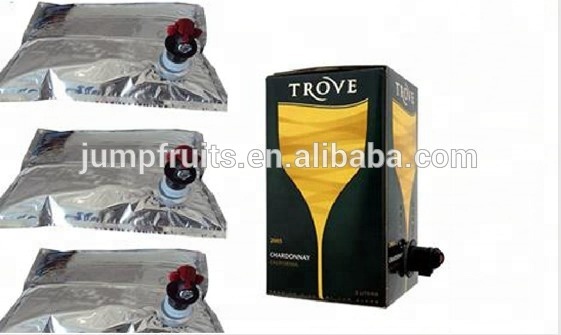

Aseptic Bag In Box Filling Machine / BIB Filling Machinery

- Machinery Capacity:

-

16000BPH

- Packaging Material:

-

plastic

- Filling Material:

-

Powder

- Type:

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

- Condition:

-

New

- Application:

-

Food

- Packaging Type:

-

Bags

- Automatic Grade:

-

Automatic

- Driven Type:

-

Electric

- Voltage:

-

220V

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Dimension(L*W*H):

-

1800*1000*1500mm

- Weight:

-

800kg

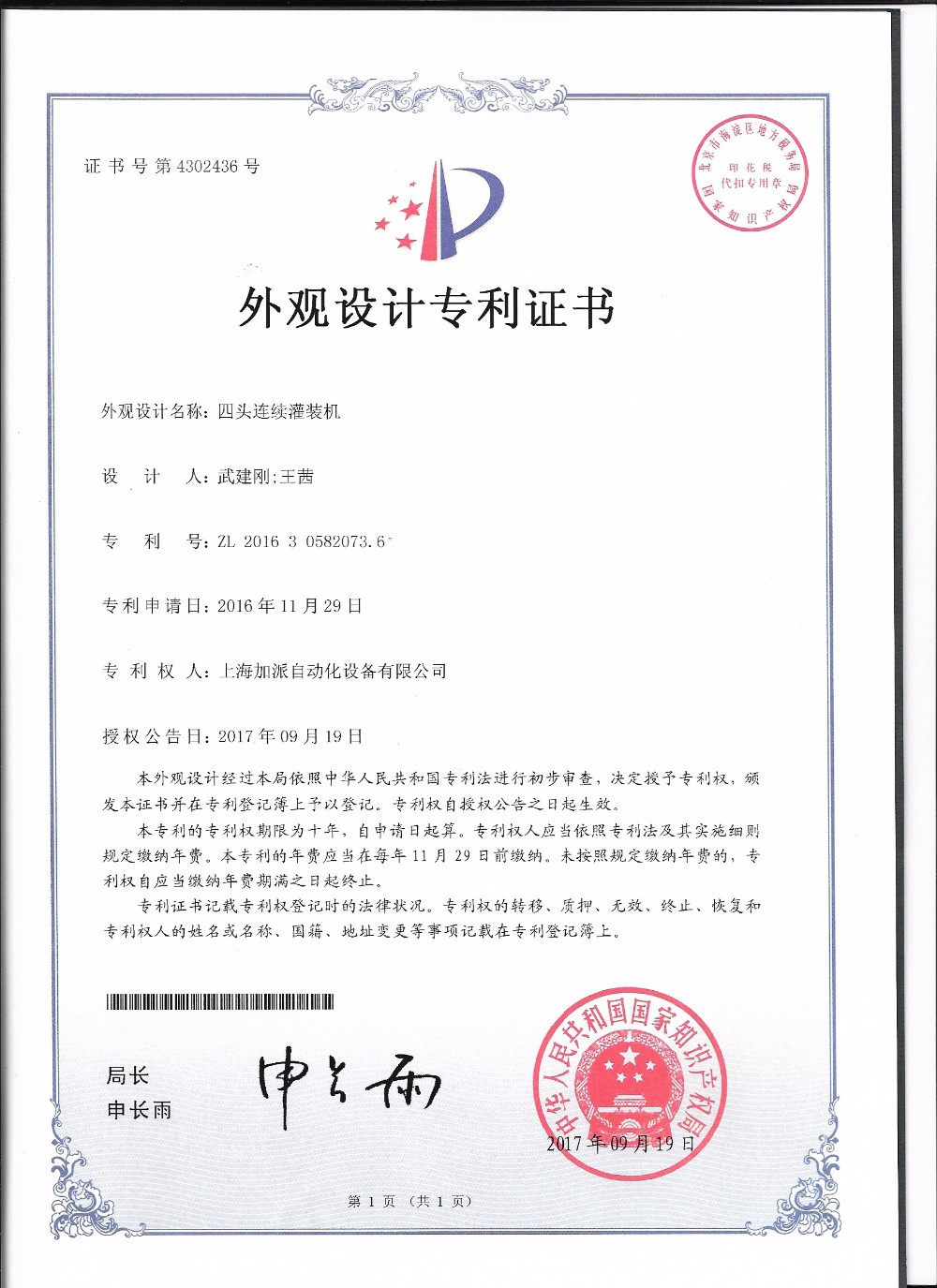

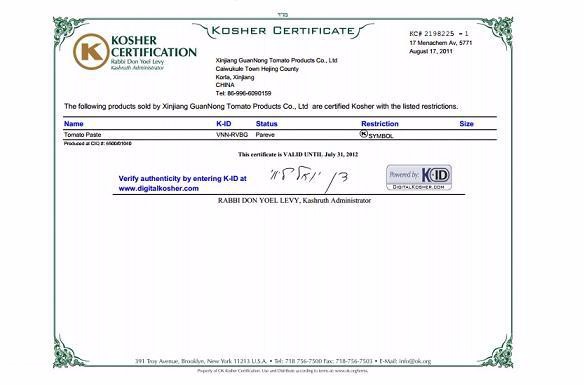

- Certification:

-

CE ISO

- After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Overseas service center available

- Warranty:

-

5 years, One Year

- Key Selling Points:

-

Easy to Operate

- Machinery Test Report:

-

Provided

- Video outgoing-inspection:

-

Provided

- Warranty of core components:

-

1 Year

- Core Components:

-

Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- Product name:

-

Aseptic bag in box filling machine/BIB filling machinery

- Usage:

-

Juice Packaging

- Function:

-

Auto

- Processing Types:

-

aseptic bag in box filling machine

- Filling range:

-

2KG~220KG.

- Material:

-

SUS304

- Filling material:

-

Juice water

- Name:

-

aseptic bag filling machine

- Supply Ability:

- 15 Set/Sets per Month

- Packaging Details

- package in cartons

- Port

- shanghai

Aseptic bag in box filling machine/BIB filling machinery

Main characteristics are as follows:

The single-head BIB aseptic pouch filling machine is mainly used for aseptic filling of other viscous or non-viscous fluids such as fruit and vegetable juices, jam or concentrated products thereof, and dairy products.

This device is a new type of product specially developed by our company for Italian 1-30L packaging. The product has a high degree of automation and quick action, and can be operated by a single person. After bag-injection sterilization, the filling action of each bag takes 2 seconds to complete. It takes only 2 seconds from the end of the filling to the time of bag ejection (higher filling efficiency ensures less material flow and reduces the amount of material. heating).

This equipment is mainly composed of aseptic filling system, flow (quality) measurement system, belt (engineering plastics) conveying system, computer PLC control system, operation platform and so on. The packaging bag is made of aluminum-plastic composite sterile bag (2L-220L).

The steam injection method is used to sterilize the bag mouth and the filling room to ensure that the filling room is always in a sterile state, and the sterile bag mouth is sterilized, opened, filled and sealed in a sterile environment. The equipment comes with a CIP cleaning and SIP sterilization process that can be linked to a front-end sterilizer without requiring separate cleaning and sterilization.

The whole machine is made of high-quality 304L/316L materials, and the piping layout is reasonable without dead ends. Both circulating steam and compressed air are discharged outside the aseptic filling plant via corresponding pipes.

Aseptic bag in box filling machine

Basic parameters:

1,Model:JUMP-HZD-1 type

2,Filling capacity: 300-2000KG/Hr

3,Fillable Sterile Pouches Range: 1 Liter-220 Liter

4,The maximum filling speed: 250 bags/Hr (taking a 5L volume as an example)

5,Motor power: 1KW.

6,Measure mode: Adopt Cologne flowmeter measurement method in Germany, the filling volume error is ≤ 0.5%.

7,Compressed air consumption: 30m3/Hr (≥0.6MPa).

8,Steam consumption: 30Kg/Hr (≥4kg/cm2).

9,Dimensions: 1200*1000*1900MM(Length*Width*Height)

Automatic Aseptic BIB Filling Machine

After-sale service

1.Installation and commissioning: We will send experienced engineering and technical personnel to be responsible for the installation and commissioning of the equipment until the equipment is qualified to ensure that the equipment is in time and put into production;

2.Regular visits:To ensure the long-term stable operation of the equipment, we will be based on customer needs, provide one to three times a year to come to technical support and other integrated services;

3.Detailed inspection report: Whether the inspection regular service, or the annual maintenance, our engineers will provide a detailed inspection report for the customer and the company reference archive, in order to learn the equipment operation at any time;

4.Fully complete parts inventory: In order to reduce the cost of parts in your inventory, provide better and faster service, we prepared a complete inventory of parts of equipment, to meet customers possible period of want or need;

5.Professional and technical training:In order to ensure the performance of the customer’s technical personnel to become familiar with the equipment, correctly grasp the equipment operation and maintenance procedures, in addition to install on-site technical training. Besides, you also can hold all kinds of professionals to the factory workshops, to help you faster and more comprehensive grasp of technology;

6.Software and consulting services:In order to allow your technical staff to have a greater understanding of the equipment related counseling, I will arrange to send the equipment regularly sent to the advisory and latest information magazine.No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Why choose us?

1.”Quality is priority”. we always attach great importance to quality control from the very beginning to the very end;

2.we have a professional manufacture experience and machining equipment;

3.we are factory ,we can provide you the super quality and very competitive price;

4.company has a quality,young,innovative and strong scientific research technical team

Is your price competitive?

surely we will give you best factory price based on superior product and service.

Any warranty?

1.one year equipment warranty after successful installation & commissioning of equipment and maintenance for lifelong time;

2.free installation and test before sending and free training for operation

3.advice for the solutions best for customers requirements

How abo