Wholesale Discount Pasta Hoister - High Profitable Carbonate Drink Processing Line / Soda Production Line – JUMP

Wholesale Discount Pasta Hoister - High Profitable Carbonate Drink Processing Line / Soda Production Line – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Model Number:

-

cts090511

- Type:

-

beverage processing line

- Voltage:

-

380V

- Power:

-

4kw

- Weight:

-

100T

- Dimension(L*W*H):

-

1720*1160*1280mm

- Certification:

-

CE ISO

- Warranty:

-

12 Months,but life-long service

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

carbonate drink production line

- Function:

-

whole processing line

- Production capacity:

-

0.5-500T/H

- Raw material:

-

fresh ripe fruits

- Usage:

-

processing and distribution

- Capacity:

-

1-5t/h

- Advantage:

-

life-long after-sales Service

- Material:

-

SUS304

- Application:

-

fruits and vegetables

- Supply Ability:

- 10 Set/Sets per Month

- Packaging Details

- Standard export package.If customer have specail requirement,we will do as customer require

- Port

- Shanghai Port

- Lead Time :

- 60days

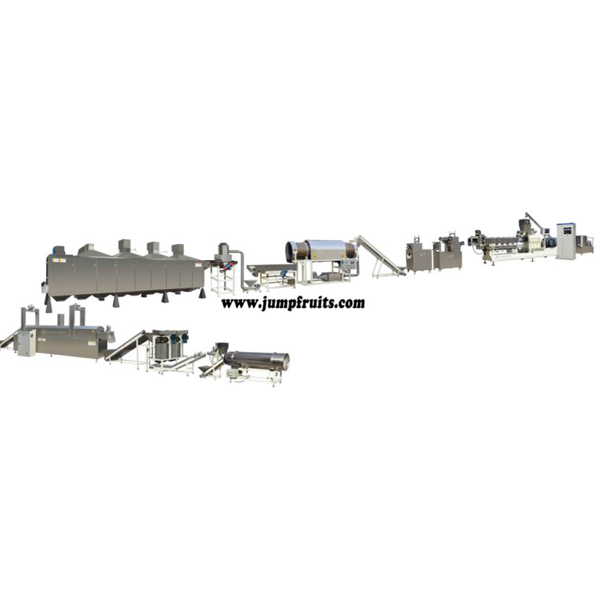

Beverage equipment & production line

* Production output from 1000-35000 bottles per hour.

* Packaging forms include cans, PET bottles, glass bottles, roof bags, sterile soft packs

* Flexible production line configuration, according to customer needs of different end products, you can configure different functions of the device

* Available basket-type, continuous counter-current and other means of extraction

* The entire line of modular design, a combination of different processing technology

* High degree of automation, saving labor

* With cleaning system, easy to clean

* System materials contact part of all 304 stainless steel, in full compliance with food hygiene and safety requirements

Package: glass bottle, PET plastic bottle, cans, aseptic soft package, roof pack 2L-220L sterile bag, carton package, plastic bag, 70-4500g tin can.

Whatsapp/Line/Wechat/Mobile: 008613681836263 Welcome any inquiry!

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of “Quality and Service Branding”, after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

Beverage equipment & production line

For green tea, black tea, oolong tea and other processing, can produce tea drinks (fruit, milk flavor), concentrated tea juice, tea powder and other products. The production line mainly consists of extraction system, heat exchanger, filter, disc centrifuge, dissolving sugar system, sterilization machine, filling machine, inverted bottle sterilizer and tunnel cooler. This production line is designed with advanced concept and high degree of automation; The main equipment is all made of high-quality stainless steel, which fully meets the hygienic requirements of food processing

.We can suggest customer the most suitable machine according to their formula and Raw material. “Design and development”, “manufacturing”, “installation and commissioning”, “technical training” and “after sales service”. We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

After-sale service

1.Installation and commissioning: We will send experienced engineering and technical personnel to be responsible for the installation and commissioning of the equipment until the equipment is qualified to ensure that the equipment is in time and put into production;

2.Regular visits:To ensure the long-term stable operation of the equipment, we will be based on customer needs, provide one to three times a year to come to technical support and other integrated services;

3.Detailed inspection report: Whether the inspection regular service, or the annual maintenance, our engineers will provide a detailed inspection report for the customer and the company reference archive, in order to learn the equipment operation at any time;

4.Fully complete parts inventory: In order to reduce the cost of parts in your inventory, provide better and faster service, we prepared a complete inventory of parts of equipment, to meet customers possible period of want or need;

5.Professional and technical training:In order to ensure the performance of the customer’s technical personnel to become familiar with the equipment, correctly grasp the equipment operation and maintenance procedures, in addition to install on-site technical training. Besides, you also can hold all kinds of professionals to the factory workshops, to help you faster and more comprehensive grasp of technology;

6.Software and consulting services:In order to allow your technical staff to have a greater understanding of the equipment related counseling, I will arrange to send the equipment regularly sent to the advisory and latest information magazine.No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Why choose us?

1.”Quality is priority”. we always attach great importance to quality control from the very beginning to the very end;

2.We have a professional manufacture experience and machining equipment;

3.We are factory ,we can provide you the super quality and very competitive price;

4.Company has a quality,young,innovative and strong scientific research technical team

Is your price competitive?

surely we will give you best factory price based on superior product and service.

Any warranty?

1.one year equipment warranty after successful installation & commissioning of equipment and maintenance for lifelong time;

2.free installation and test before sending and free training for operation

3.advice for the solutions best for customers requirements

How about the test running & installation?

1.Before delivery, we finish the test over 3 times.

2.If you take integral design, no need to installation at all. If parted design, we can send our technicians to your place if necessary.

How to choose your wanted type?

1.Tell us your requirement of the productivity.

2.You know about our machines ,the just tell us the type.

3.Give us the detailed information about your raw material,Picture will be best

Product detail pictures:

Related Product Guide:

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Wholesale Discount Pasta Hoister - High Profitable Carbonate Drink Processing Line / Soda Production Line – JUMP , The product will supply to all over the world, such as: Guyana, Los Angeles, India, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.