Well-designed Whole Milk Powder Production Line - Small Scale Milk And Yogurt Cheese Processing Line – JUMP

Well-designed Whole Milk Powder Production Line - Small Scale Milk And Yogurt Cheese Processing Line – JUMP Detail:

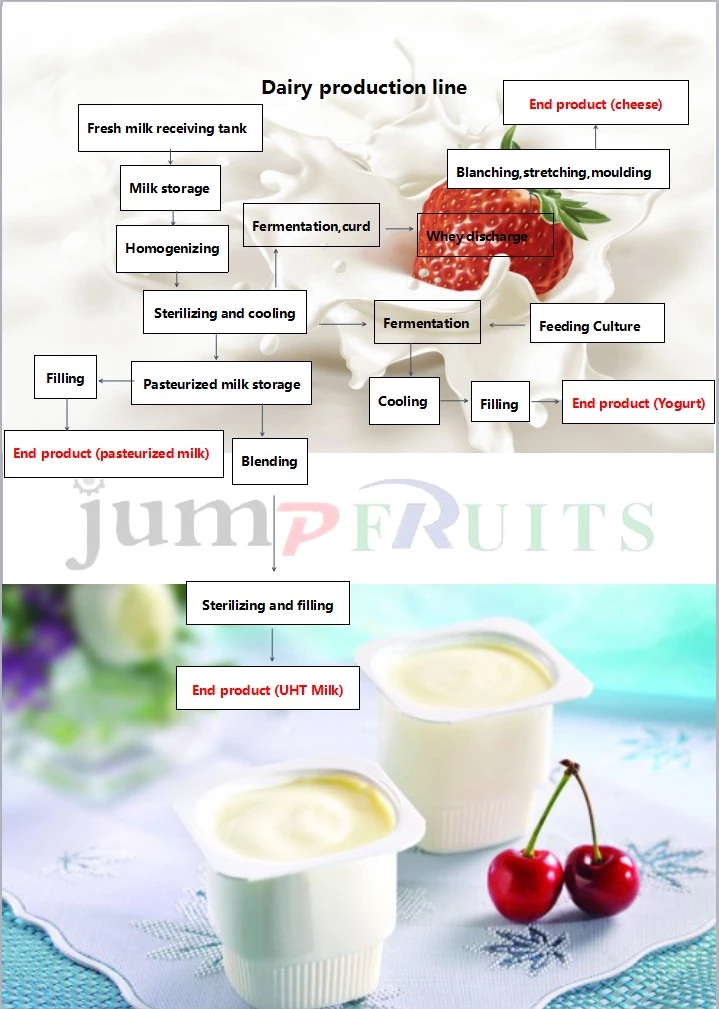

Fresh milk temporary storage → fresh milk net milk (net milk machine) → fresh milk cooling → fresh milk temporary storage → raw and auxiliary material mixing (high speed mixing tank) → liquid preheating (plate type sterilization machine) → material liquid homogenization (high pressure Homogenizer)→Pasteurization (tuber sterilization machine) → Insulation sterilization (insulation sterilization tube) → Liquid cooling (plate heat exchanger) → Strain input (yoghurt fermenter) → Insulation culture (yoghurt fermenter) →→ Fermentation termination (yoghurt fermenter)→semi-finished product cooling→temporary storage→aseptic mixing (semi-finished storage tank)→product packaging (fruit)→finished cold storage (shallow cold storage).

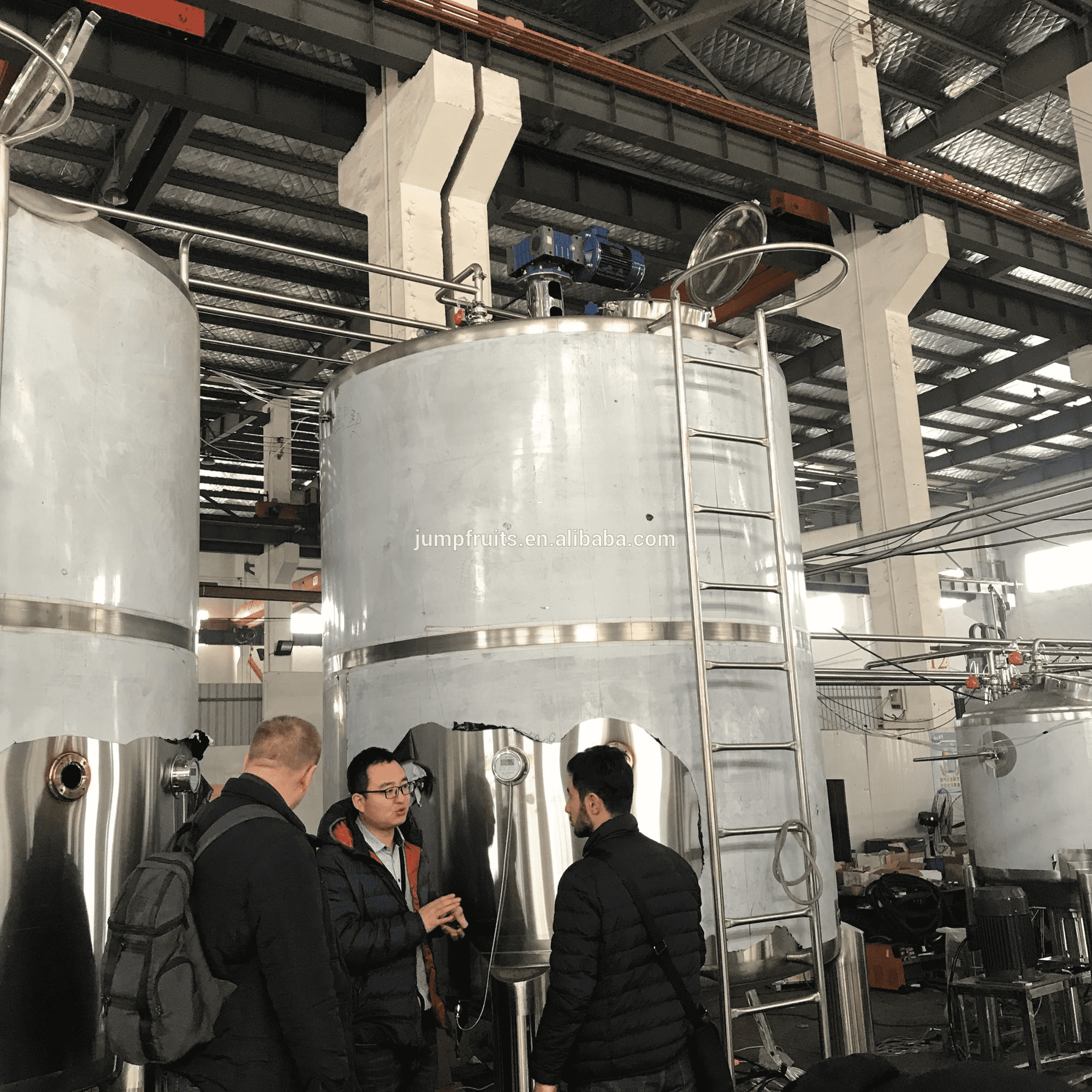

500L yogurt Fementation tank

Volume:200L-5000L can be customized

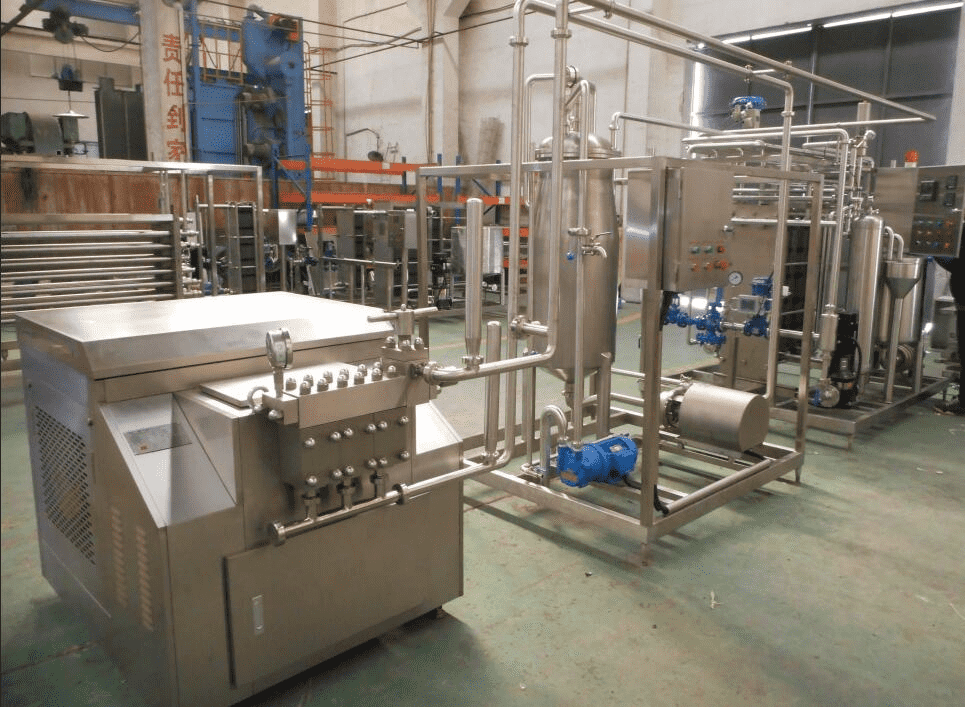

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

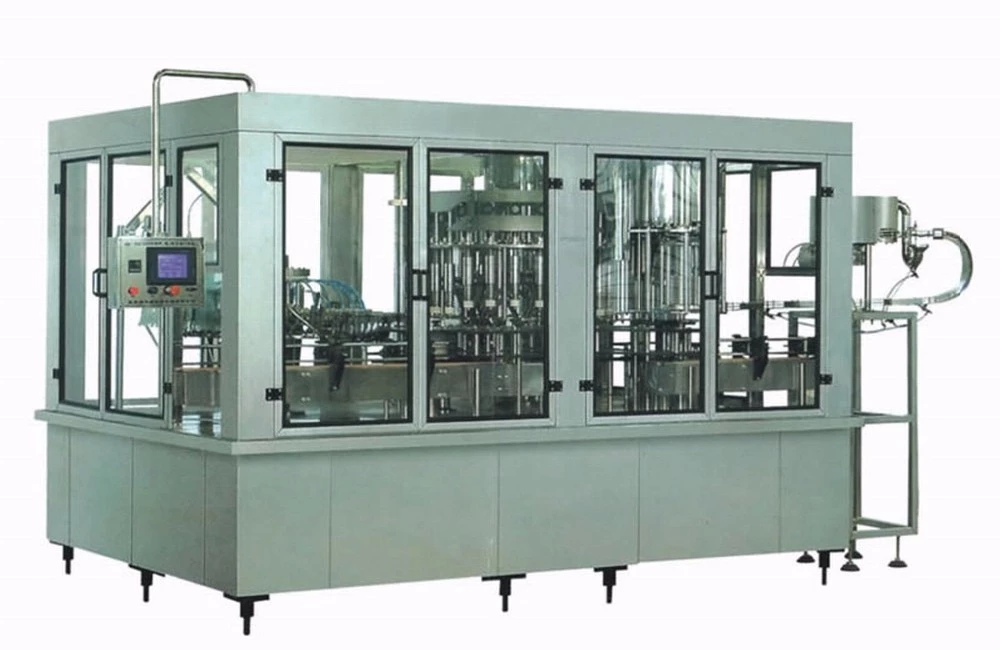

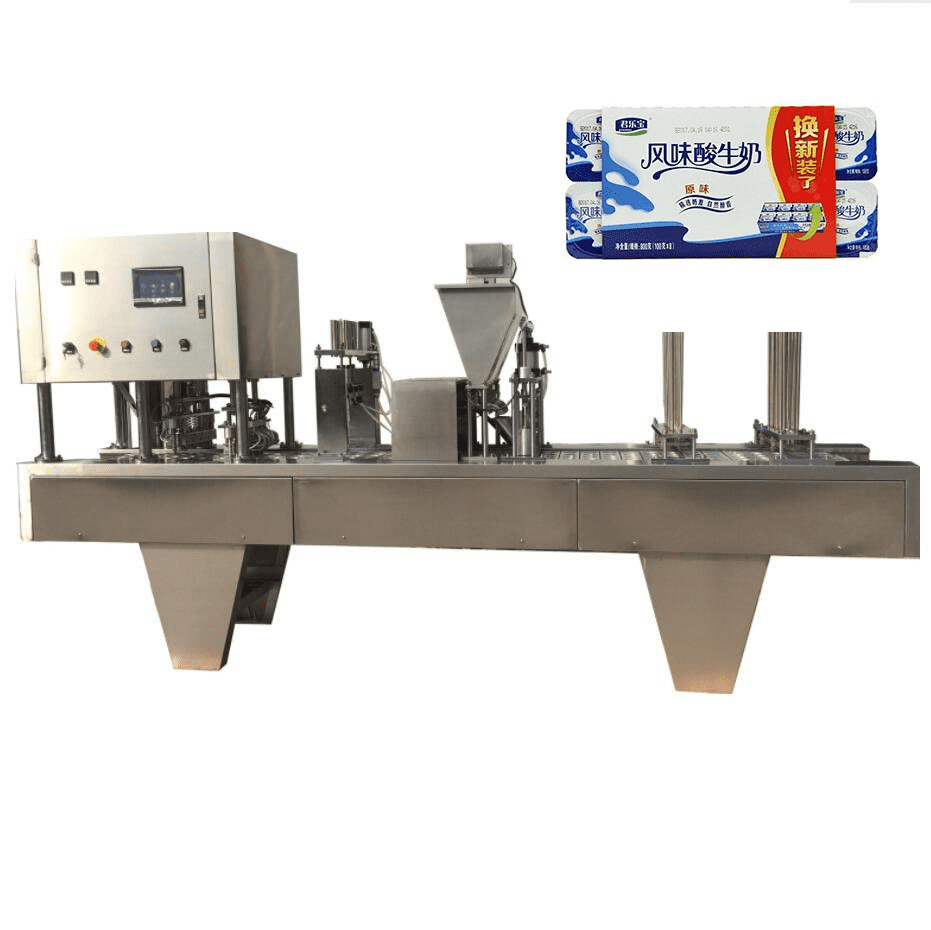

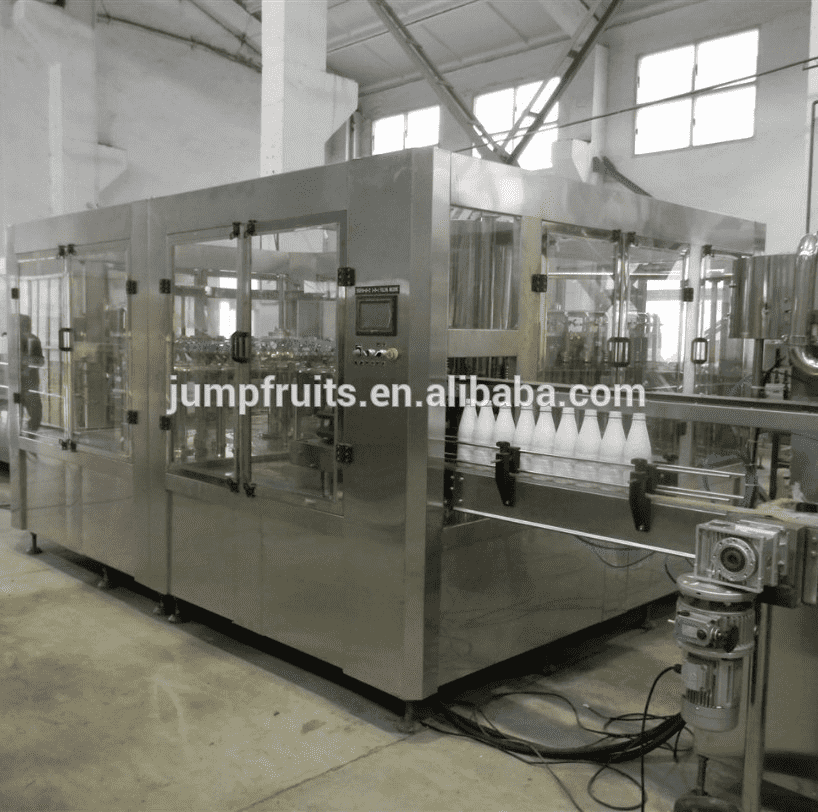

Filling maching

Specially suitable for tomato paste, mango puree and other viscous product.

35-50 bottle per min

Filling sachet valume:10-500g

Contact Us

Salemanager: Nina

Whatsapp: +86 13681836263

Product detail pictures:

Related Product Guide:

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Well-designed Whole Milk Powder Production Line - Small Scale Milk And Yogurt Cheese Processing Line – JUMP , The product will supply to all over the world, such as: Germany, Maldives, South Africa, we've got all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!