Rapid Delivery for Charente Distiller - Advanced Customized Buckwheat Flour Production Line For Flour Mill And Plant Flour Machinery – JUMP

Rapid Delivery for Charente Distiller - Advanced Customized Buckwheat Flour Production Line For Flour Mill And Plant Flour Machinery – JUMP Detail:

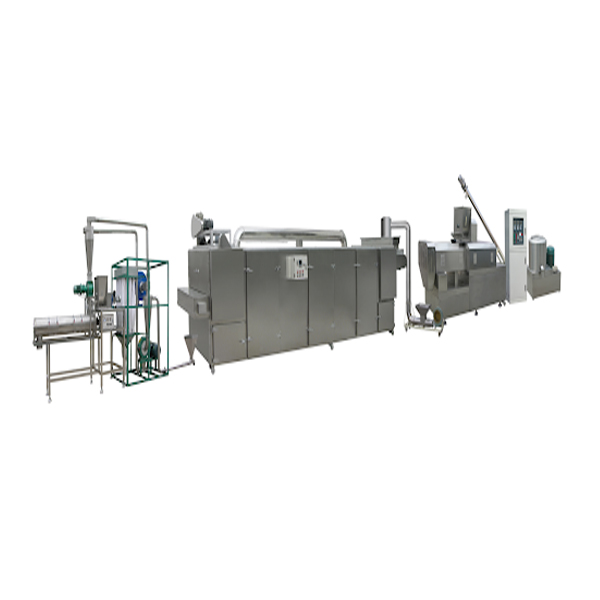

Advanced Customized Buckwheat Flour Production Line

For Flour Mill And Plant Flour Machinery

Production process: mixing powder → feeding → puffing → drying → crushing → storage or packaging

Production capacity (kg): 150-1000kg

Feeding particles (mm): <10mm

Crushing fineness (mm): 20-120mm

Spindle speed r/min : 2800

Motor power (kw): 18.5kw

Vacuum motor (kw): 3kw

Cutting motor (kw): 0.75kg

Dimensions (mm): 4800×1100×2700

The production capacity is 50kg/time.

The contact part is stainless steel.

The mixing barrel has a built-in spiral mixing blade.

The upper part is the mixer, the lower part is the temporary storage barrel

Drive power: 0.75 kw

Production capacity: with the host

Dimensions: 3000×850×2400mm

Function: Convey the mixed raw materials to the extruder.

Total power: 99kw

Main drive power: 75 kw, frequency conversion speed regulation

Rotary cutting power: 1.5 kw, frequency conversion speed regulation

Feeding power: 1.5 kw, frequency conversion speed regulation

Heating power: 21kw

Production capacity: 400-500kg/h

Overall dimensions of the host: 4000×1200×2200 (mm)

Overall dimensions of the control cabinet: 600×1000×1800 (mm)

Function: Puffing into semi-finished products.

ETC.

Shanghai Jump automatic equipment Co., Ltd. is modern high-tech joint-stock enterprises, formerly known as Shanghai Qianwei machinery plant, also named as Jump Machinery (Shanghai) Limited. which professional engaged in whole plant equipment design, manufacturing, R & D and turnkey project for juice and jam, all kinds of fruits processing, juice drinks, tea drinks, yogurt, cheese and liquid milk dairy processing etc.

It has best projects, professional engineers and technicians, strong R&D department with a number of masters and PhD of food engineering & packaging machinery, stable long-term development and highly rated customer experience. Our projects have been established in every province and city in China. We also steadily cooperate with our overseas clients from Africa, the Middle East, Southeast Asia, Oceania, Europe and America.

Our main production line

1. Tomato paste / puree / jam / concentrate, ketchup, chilli sauce , other fruit & vegetables sauce / jam processing line

2. Fruit & vegetables ( orange , guava, cirtrus, grape, pinapple, cherry, mango, apricot.etc. ) juice and pulp processing line

3. Pure, mineral water, Mixed beverage, drink (soda, Cola, Sprite, carbonated beverage, no gas fruit drink, herbal blend drink, beer,cider, fruit wine .etc. ) production line

4. Canned fruit & vegetables ( tomato, cherry, beans, mushuroom, yellow peach, olives, cucumber, pineapple, mango, chili, pickles and so on. ) production line

5. Dried fruit & vegetables ( dried mango, apricot, pineapple, raisin, blueberry .etc. ) production line

6. Dairy (UHT milk, pasteurized milk, cheese, butter, yogurt, milk powder, margarine, ice cream)production line

7. Fruit and vegetable powder (Tomato, pumpkin, cassava powder, strawberry powder, blueberry powder, bean powder, etc. ) production line

8. Snack (Dried freeze-dried fruit, puffed food, french fried potato chips, etc. ) production line

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for Rapid Delivery for Charente Distiller - Advanced Customized Buckwheat Flour Production Line For Flour Mill And Plant Flour Machinery – JUMP , The product will supply to all over the world, such as: Adelaide, Sacramento, Romania, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our products, please do not hesitate to contact us, we will be happy to provide you with further information!

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!