Quality Inspection for Cranberry Processing Machine And Production Line - Automatic Production Line For Sugarcane Juice Concentrate Making Machine – JUMP

Quality Inspection for Cranberry Processing Machine And Production Line - Automatic Production Line For Sugarcane Juice Concentrate Making Machine – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JPF-DPL006

- Type:

-

production line for sugarcane juice

- Voltage:

-

380V/220V

- Power:

-

4kw

- Weight:

-

30TONS

- Dimension(L*W*H):

-

1180*680*1800

- Certification:

-

CE Certificate

- Warranty:

-

12 Months

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Material:

-

Food Grade Stainless Steel 304

- Capacity:

-

500 T/D

- Supply Ability:

- 8 Set/Sets per Month production line for sugarcane juice

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage.

- 2.Wound plastic film keeps machine out of damp and corrosion.

- 3.Fumigation-free package helps the smooth customs clearance.

- 4.The big size machine will be fixed in container without package.

- Port

- Shanghai

- Lead Time :

- 50 days

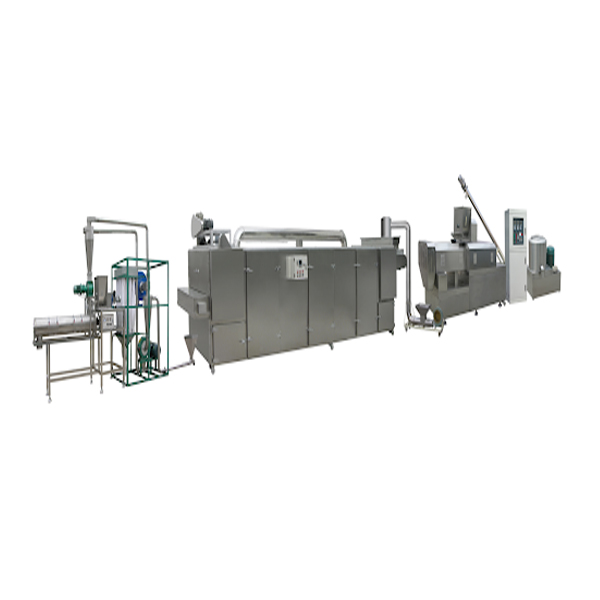

Production line for sugarcane juice

This machine has washing ,filling and capping three functions in one body, total process is automatic, and it is suitable for high temperature resistant PET bottled juice and tea drink filling, it applies advanced micro-pressure gravity type filling principle, with perfect re-circulation system, without contacting with material, avoid secondary pollution and oxidation. It is made of high quality SUS304 stainless steel,the material of parts inside of the filling valve must be SUS316 . Main components are processed precisely by CNC machine tools. The machine adopts advanced photo electricity to detect running status. No bottle no filling. It is possible to realize man-machine conversation because of applying touch screen for operation.

Main Features

PET Bottle Fruit Juice Liquid Filling Machine—-Main performance

●Bottle is entered by air conveyor, the speed of bottle entering is fast and bottle shape is not changed because of adopting hanging clamping bottleneck way.

●Adopting clamping bottleneck way to wash bottle mouth and avoiding touch screw mouth, adopting clamping bottleneck way in the whole conveying process. When bottle type changes, you need to change the board related with bottle diameter.

●Filling adopts cylinder feeding structure, filling valve adopts high filling speed and mass flow rate valve which control liquids level accurately and without loss.

●The capping system applies advanced French technology, when clamp the cap will screw immediately and magnetic torque type capping head.

●Main PLC and frequency changer are used famous brand, such as Mitsubishi and Omron etc.

Select stainless steel bracket, food-grade and hard plastic or stainless steel scraper, smoothing blade architecture to prevent the fruit jam; Using imported anti-corrosion bearings, double-sided seal; with continuously variable transmission motor, variable frequency Speed and low operating costsTitle goes here.

Stainless steel roller conveyor, rotation and solution, a full range of check, no need ends. Manmade fruit platform, painted carbon steel bracket,stainless steel antiskid pedal,stainless steel fence.

C. Crusher and Pulp

Fusing Italian technology, multiple sets of cross-blade structure, crusher size can be adjusted according to customer or specific project requirements, it will increase the juice juice rate of 2-3% relative to the traditional structure , which is suitable for production of onion sauce, carrot sauce, pepper sauce , apple sauce and other fruits and vegetables sauce and products

D. Extractor

It have tapered mesh structure and the gap with load can be adjusted, frequency control, so that the juice will be cleaner; Internal mesh aperture are based on customer or specific project requirements to order

E. Evaporator

Single-effect, double-effect,triple-effect and multi-effect evaporator, which will save more energy; Under vacuum, continuous low temperature cycle heating to maximize the protection of nutrients in the material as well as the originals. There are steam recovery system and double times condensate system, it can reduce the consumption of steam;

F. Sterilization machine

Having obtained nine ed technology, take full advantages of the material’s own heat exchange to save energy– about 40%

F. Filling machine

Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return; Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ; In the filling process,using turntable lifting mode to avoid secondary pollution.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for Quality Inspection for Cranberry Processing Machine And Production Line - Automatic Production Line For Sugarcane Juice Concentrate Making Machine – JUMP , The product will supply to all over the world, such as: Finland, Czech Republic, Russia, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.