Quality Inspection for Canned Mushrooms Processing Machine - Soft candy machine – JUMP

Quality Inspection for Canned Mushrooms Processing Machine - Soft candy machine – JUMP Detail:

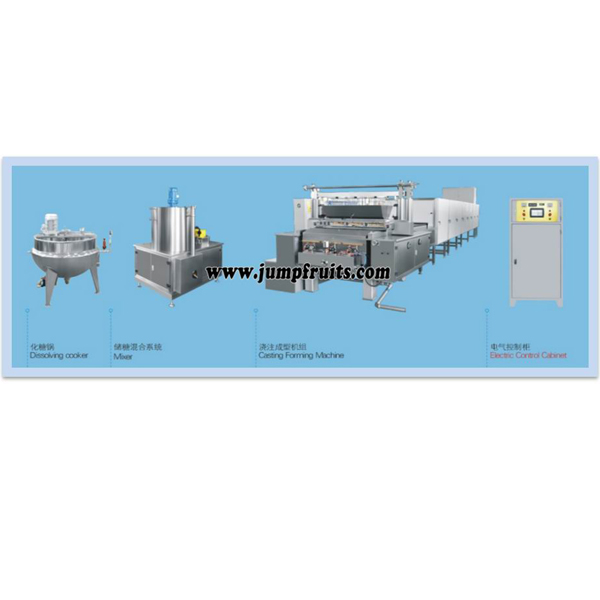

Soft candy machine and production line process flow:

(1)sugar dissolving; (2) sugar conveying; (3)keepng warm in storage tank; (4)mixing for flavor and sugar; (5)syrup into hopper; (6) depositing (contering filling )forming; (7)cooling into tunnel; (8)demoulding and cooling with conveying out; (9) Packing.

Candy (English: sweets) can be divided into hard candy, hard sandwich candy, milk candy, gel candy, polished candy, gum based candy, inflatable candy and pressed candy. Among them, hard candy is a kind of hard and crisp candy with white granulated sugar and starch syrup as the main materials; hard sandwich candy is hard candy with filling core; milk candy is made of white granulated sugar, starch syrup or other sugar, oil and dairy products as the main materials, with egg white quality no less than 1.5%, fat not less than 3.0%, with special creamy flavor and burnt flavor; Gel candy is a soft candy made of edible gum (or starch), white granulated sugar and starch syrup (or other sugar) as main material; polished candy is a solid and solid candy; gum based candy is a chewing or bubbling candy made of white granulated sugar (or sweetener) and rubber based material; inflatable candy is a candy with fine, uniform bubbles inside the sugar body. Pressed candy is a kind of candy which is granulated, bonded and pressed.

| Soft candy equipment Major parameter | |||||

|

1) |

Capacity | 150kgs /h | ( speed is adjstable ) | ||

|

2) |

Max candy weight | 26g | |||

|

3) |

Depositing speed | 45-50n/min | |||

|

4) |

Working Environment temperature | <25℃ | |||

|

5) |

Humidity |

55% |

|||

|

6) |

Steam requirement | 500kg/h , 0.5-0.8MPa | |||

|

7) |

Air compress | :0.25m3/min,0.4~0.6MPa | |||

|

8) |

Power | 18kW/380V/50HZ | |||

|

9) |

Length | 18m | |||

|

10) |

Weight | 3000kgs | |||

Product detail pictures:

Related Product Guide:

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Quality Inspection for Canned Mushrooms Processing Machine - Soft candy machine – JUMP , The product will supply to all over the world, such as: Palestine, Rio de Janeiro, Atlanta, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.