PriceList for Sweets Production Line - Automatic Pineapple Concentrate Juice Processing Plant – JUMP

PriceList for Sweets Production Line - Automatic Pineapple Concentrate Juice Processing Plant – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

OEM

- Model Number:

-

JUMP-FQJL

- Type:

-

pineapple peeling machine

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

60 TONS

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

ISO 9001,CE

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

pineapple juice machine

- Material:

-

304 Stainless Steel

- Feature:

-

Turn Key Project

- Application:

-

Pineapple

- Function:

-

Extracting

- Usage:

-

Pressing Fruits

- Capacity:

-

1500kg/h

- Supply Ability:

- 3 Set/Sets per Month juice making machine

- Packaging Details

- carton box

- Port

- shanghai

- Lead Time :

- 50 days

Product Application

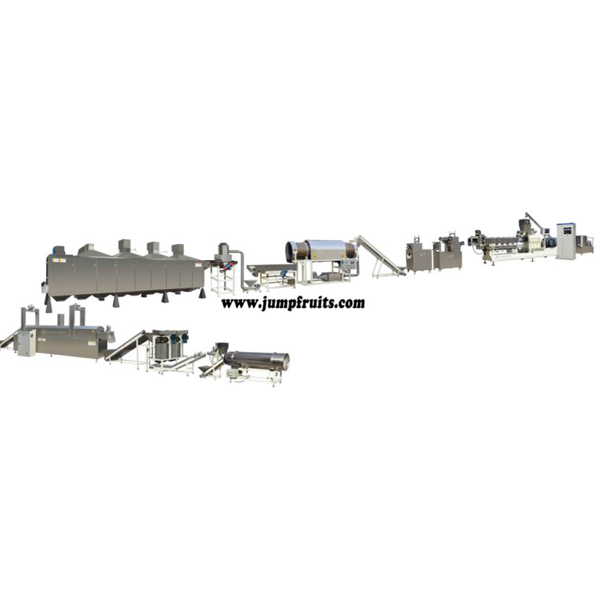

Automatic pineapple juice processing plant

This machine has washing ,filling and capping three functions in one body, total process is automatic, and it is suitable for high temperature resistant PET bottled juice and tea drink filling, it applies advanced micro-pressure gravity type filling principle, with perfect re-circulation system, without contacting with material, avoid secondary pollution and oxidation. It is made of high quality SUS304 stainless steel,the material of parts inside of the filling valve must be SUS316 . Main components are processed precisely by CNC machine tools. The machine adopts advanced photo electricity to detect running status. No bottle no filling. It is possible to realize man-machine conversation because of applying touch screen for operation.

Washing Parts

It adopts rotary design, which mainly used for washing empty bottles of juice and water etc. Then transfer the clean bottles into filling part.

PET bottles entrance to equipments by star wheel, the bottles clamped and reversed to make the bottle down. Washing with sterilizing water and drain well, then turn over the bottle up automatically. Main structure and washing part are made by stainless steel, simple structure and easy adjustable; Less contact with bottleneck, which can avoid secondary pollution effectively.

Filling Part

This Filling Machine is design by XINMAO, Filling valve adopts negative filling way, filling fast and sensitive; the precision of filling liquid surface is high; There is no spring in valve, materials don’t contact with the spring directly, which is good for cleaning valve. To make sure the filling process and filling temperature, when there is no bottle or closed down, the materials in valve is under micro back flow condition. Whole machine are controlled by PLC automatically.

UHT milk processing line

91.8% Response Rate

Tomato paste in bulk

91.8% Response Rate

Tomato paste evaporator

91.8% Response Rate

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for PriceList for Sweets Production Line - Automatic Pineapple Concentrate Juice Processing Plant – JUMP , The product will supply to all over the world, such as: Nairobi, Frankfurt, Zambia, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.