Volume:200L-5000L can be customized

Popular Design for Tea Beverage Processing Machine - Industrial Frozen Fruit Yogurt Production Line – JUMP

Popular Design for Tea Beverage Processing Machine - Industrial Frozen Fruit Yogurt Production Line – JUMP Detail:

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

1 Year

- Core Components:

-

Motor

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Voltage:

-

220V/380V

- Power:

-

Variable

- Weight:

-

100kg-5000kg

- Dimension(L*W*H):

-

Standard Size

- Certification:

-

CE, ISO9001

- Warranty:

-

1 Year

- Key Selling Points:

-

High Productivity

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

Industrial frozen yogurt production line with fresh fruit diced

- Production capacity:

-

100kg-10T/H from fresh milk and diced fruits

- Material:

-

SUS 304 Food grade

- Function:

-

blending, seperator, fementation,filling

- Usage:

-

industrial yogurt production line

- Processing Types:

-

Complete yogurt Processing plant

- Final product:

-

frozen pasteurized yogurt

- Capacity:

-

1-100 Ton/Day

- Supply Ability:

- 10 Set/Sets per Month industrial yogurt making machine

- Packaging Details

- standard export shipping standard.If you have your instruction,we will follow

- Port

- shanghai port

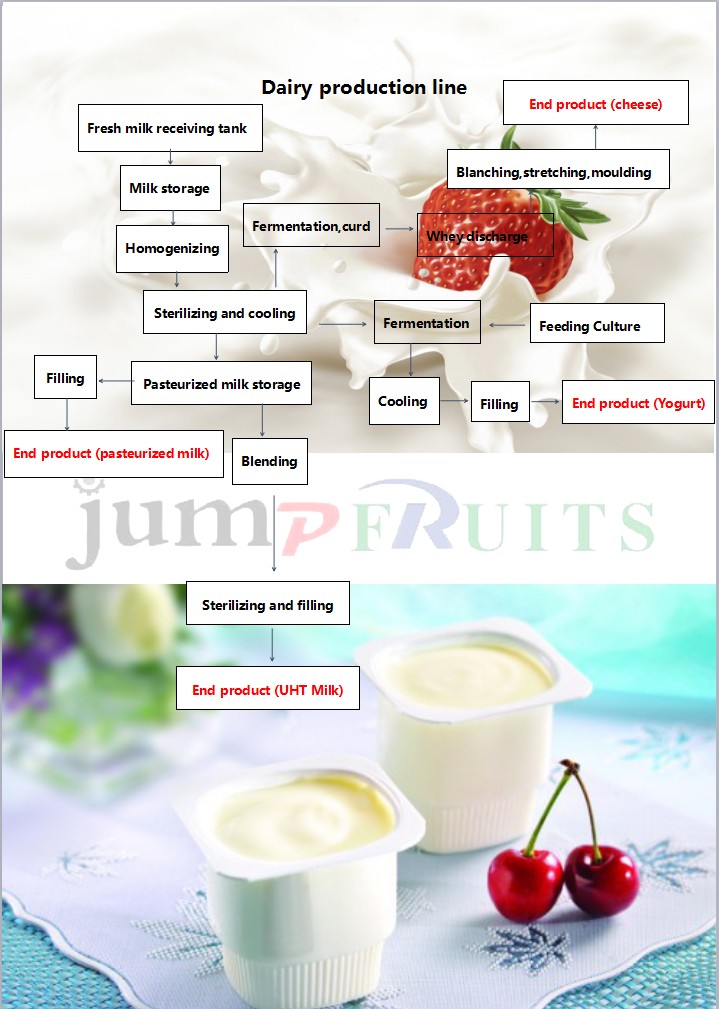

Industrial fruit yogurt production line / making machine:

Yogurt production process

Fresh milk temporary storage → fresh milk net milk (net milk machine) → fresh milk cooling → fresh milk temporary storage → raw and auxiliary material mixing (high speed mixing tank) → liquid preheating (plate type sterilization machine) → material liquid homogenization (high pressure Homogenizer)→Pasteurization (tuber sterilization machine) → Insulation sterilization (insulation sterilization tube) → Liquid cooling (plate heat exchanger) → Strain input (yoghurt fermenter) → Insulation culture (yoghurt fermenter) →→ Fermentation termination (yoghurt fermenter)→semi-finished product cooling→temporary storage→aseptic mixing (semi-finished storage tank)→product packaging (fruit)→finished cold storage (shallow cold storage).

Main Features

we take advantages of the comprehensive and technical cooperation with the Italian company partner, now in fruit processing, cold breaking processing, multi effect energy saving concentrated, sleeve type sterilization and aseptic big bag canning has made domestic and unmatched technical superiority. We can provide the entire production line processing 500KG-1500 tons of raw fruit daily according to the customers.

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of "Quality and Service Branding", after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

500L yogurt Fementation tank

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

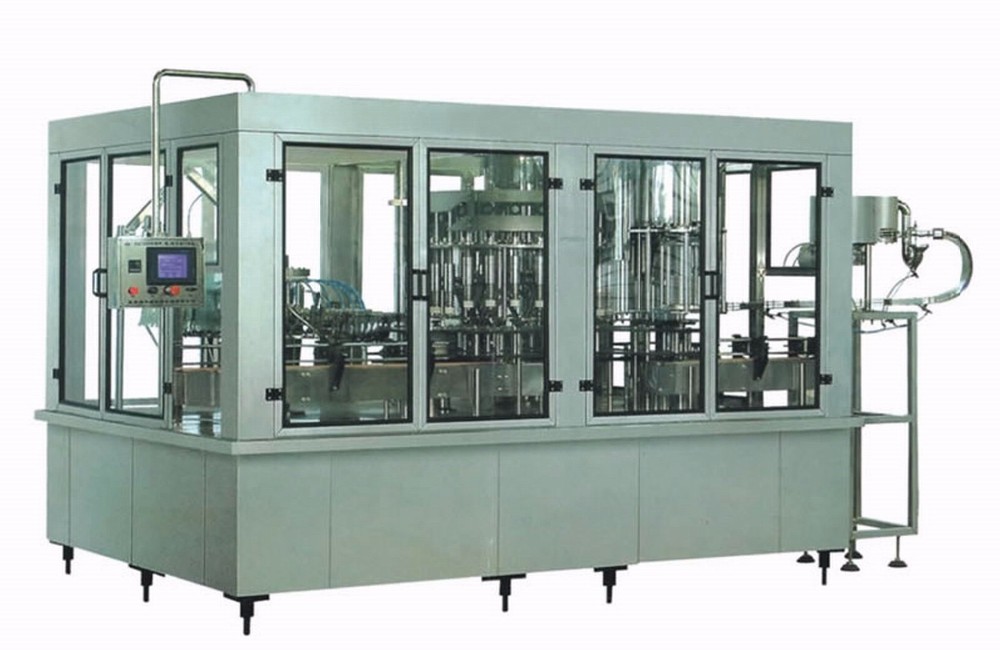

Filling maching

Specially suitable for tomato paste, mango puree and other viscous product.

35-50 bottle per min

Filling sachet valume:10-500g

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

|

Our Main Business Products

|

||

|

1

|

Tomato paste / puree / jam / concentrate, ketchup, chilli sauce , other fruit & vegetables sauce / jam processing line

|

|

|

2

|

Fruit & vegetables ( orange , guava, cirtrus, grape, pinapple, cherry, mango, apricot.etc. ) juice and pulp processing line

|

|

|

3

|

Pure, mineral water, Mixed beverage, drink (soda, Cola, Sprite, carbonated beverage, no gas fruit drink, herbal blend drink, beer,cider, fruit wine .etc. ) production line

|

|

|

4

|

Canned fruit & vegetables ( tomato, cherry, beans, mushuroom, yellow peach, olives, cucumber, pineapple, mango, chili, pickles and so on. ) production line

|

|

|

5

|

Dried fruit & vegetables ( dried mango, apricot, pineapple, raisin, blueberry .etc. ) production line

|

|

|

6

|

Dairy (UHT milk, pasteurized milk, cheese, butter, yogurt, milk powder, margarine, ice cream)production line

|

|

|

7

|

Fruit and vegetable powder (Tomato, pumpkin, cassava powder, strawberry powder, blueberry powder, bean powder, etc. ) production line

|

|

|

8

|

Leisure snack (Dried freeze-dried fruit, puffed food, french fried potato chips, etc. ) production line

|

|

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.

Product detail pictures:

Related Product Guide:

We insist on offering premium quality creation with very good company concept, honest product sales along with the finest and fast assistance. it will bring you not only the premium quality item and huge profit, but the most significant is to occupy the endless market for Popular Design for Tea Beverage Processing Machine - Industrial Frozen Fruit Yogurt Production Line – JUMP , The product will supply to all over the world, such as: Ethiopia, Kazakhstan, South Korea, To work with an excellent products manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.