Popular Design for Spaghetti Equipment - Complete Set Of Papaya Juice Making Machine – JUMP

Popular Design for Spaghetti Equipment - Complete Set Of Papaya Juice Making Machine – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JP-DFP0019

- Type:

-

papaya juice processing line

- Voltage:

-

220/380/440V

- Power:

-

2.2kw

- Weight:

-

500kg

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

CE/ISO9001

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

papaya juice making machine

- Material:

-

SUS 304 stainless steel

- Capacity:

-

20 to 1500 tons/day treatment capacity as customer require

- Usage:

-

Industrial Usage

- Application:

-

Pineapple

- Function:

-

Shreding

- Name:

-

Juicer

- Feature:

-

Turn Key Project

- Item:

-

Automatic Commercial Cold Press Juicer

- Color:

-

Customers' Requirements

- Supply Ability:

- 50 Set/Sets per Year papaya juice making machine

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- shanghai port

- Lead Time :

- Within 90 days

Papaya juice making machine

Our Advantages:

1.Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop services, from your warehouse designing(water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

2.15 years export experience, easily transport cargo to your door

3.customized service, we will try our best to meet your requirement.

4.Quality guarantee: 12 months. After that, engineers also available on your traval expense and spare parts cost.We offer life-long after-sale service.

Main advantages of our system line:

1. High production speed achieved by a newly designed head system (single head or twin heads available), improved reliability from a fully PLC controlled self diagnostic operational mode.

2. Greater versatility by meeting various packing standards with different products.

3 Coordinates well with the tube in tube sterilizer, if some malfunction with the filler, the product will be automatic flow back into the buffer tank before the UHT sterilizer.

4. The use of a hermetically sealed empty bag ensures the bag will remain sterile before it is filled.

5. High pressure saturated steam is used for sterilization of the fitment, cap and exposed portion of the filler prior to each filling cycle. NO CHEMICALS are required.

6. The sealing of the fill valve on the interior of the fitment keeps product completely away from the package sealing area.

7. The hermetic heat sealing of the fitment provides a tamper evident closure and a superior oxygen barrier.

8. The overall aseptic design of the filler allows uninterrupted. Operation throughout a complete tomato/fruit season, maximizing your plant’s efficiency

9. CIP and SIP available together with tube in tube sterilizer

Bucket Elevator

1. smooth bucket structure against clamping fruits, suitable for tomato, strawberry, apple, pear, apricot, etc.

2. running stably with low noise, speed adjustable by transducer.

3. anticorrosive bearings, double sides seal.

Air Blowing & Washing Machine

1 Used to wash fresh tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

Peeling, pulping & Refining Monobloc (Pulper)

1. The unit can peel, pulp and refine fruits together.

2. The aperture of strainer screen can be adjustable (change) based on customer’s requirement.

3. Incorporated Italian technology, high quality stainless steel material in contact with fruit material.

Belt press extractor

1. Widely used in extracting and dehydrating of many kinds of acinus, pip fruits, and vegetables.

2. the unit adopt advanced technology, big press and high efficiency, high degree of automatic, easy to operate and maintains.

3. the extraction rate can be get 75-85%(based on raw material)

4. low investment and high efficiency

Preheater

1. To inactivate enzyme and protect color of paste.

2. Auto temperature control and the out temperature are adjustable.

3. Multi-tubular structure with end cover

4. If the effect of preheat and extinguish enzyme failed or not enough, the product flow return to tube again automatically.

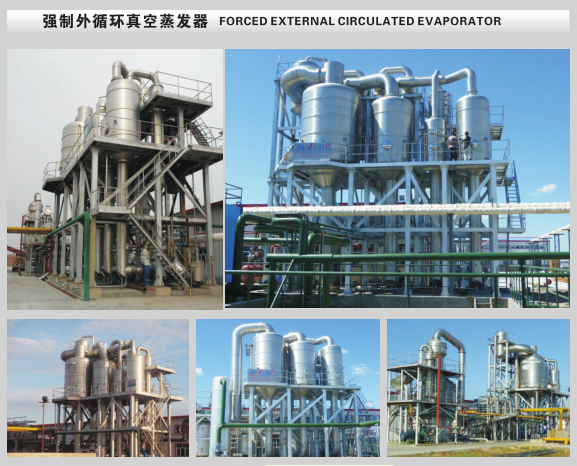

Evaporator

1. Adjustable and controllable direct contact heat treatment units.

2. Shortest possible residence time, presence of a thin film along the entire length of the tubes reduces holdup and residence time.

3. Special design of liquid distribution systems to ensure correct tube coverage. The feed enters at the top of the calandria where a distributor ensures film formation on the inside surface of each tube.

4. The vapor flow is co-current to the liquid and the vapor drag improves the heat transfer. The vapor and the remaining liquid are separated in a cyclone separator.

5. Efficient design of separators.

6. Multiple effect arrangement provides steam economy.

Tube in tube sterilizer

1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

2. Incorporated Italian technology and conform to Euro-standard

3. Great heat exchange area, low energy consumption and easy maintenance

4. Adopt mirror welding tech and keep the smooth pipe joint

5. Auto backtrack if not enough sterilization

6. CIP and auto SIP available together with aseptic filler

7. Liquid level and temp controlled on real time

Product detail pictures:

Related Product Guide:

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for Popular Design for Spaghetti Equipment - Complete Set Of Papaya Juice Making Machine – JUMP , The product will supply to all over the world, such as: Salt Lake City, Los Angeles, Anguilla, If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!