Original Factory Conditioning Equipment - Canned food machine and Jam production equipment – JUMP

Original Factory Conditioning Equipment - Canned food machine and Jam production equipment – JUMP Detail:

Fruits and vegetables tinplate can food and baby food: canned peaches, canned mushrooms, canned chili sauce, canned oranges, canned apples, canned pears, canned pineapples, canned green beans, canned bamboo shoots, canned cucumbers, canned radish, canned tomato sauce, canned cherries, canned apples, canned pears, canned pineapples, canned green beans, canned bamboo shoots, canned cucumbers, canned radish, canned tomato paste, canned cherries etc.

Canned food machine and production line packaging: glass bottles, jar PET plastic bottles, cans, aseptic flexible packaging, roof bags, 2L-220L aseptic bags, carton packaging, plastic bags, 70-4500g tin cans.

Jam production equipment is the fruit after pre-treatment, broken and boiled gel material (sugar and acidity regulator can be added). Common jams include the following: Pear paste, strawberry jam, blueberry jam, apple jam, orange peel jam, kiwi jam, orange peel jam, bayberry jam, cherry jam, carrot jam, tomato jam, aloe jam, mulberry jam, rose pear jam, hawthorn jam, pineapple jam avocado jam and so on.

Jam production process

According to the processing properties of different fruits and the final product characteristics of a reasonable choice of different processes.

Conveyor, hoist, cleaning machine, selection machine, crushing (at the same time peeled, seeded, enucleated, stemmed), boil, degassing, filling machine, secondary sterilization (after sterilization) , Air shower, labeling machine, coding, packing, storage.

Packaging: glass bottles, PET plastic bottles, zip-top can, aseptic soft package, brick carton, gable top carton, 2L-220L aseptic bag in drum, carton packaging, plastic bags, 70-4500g tin cans.

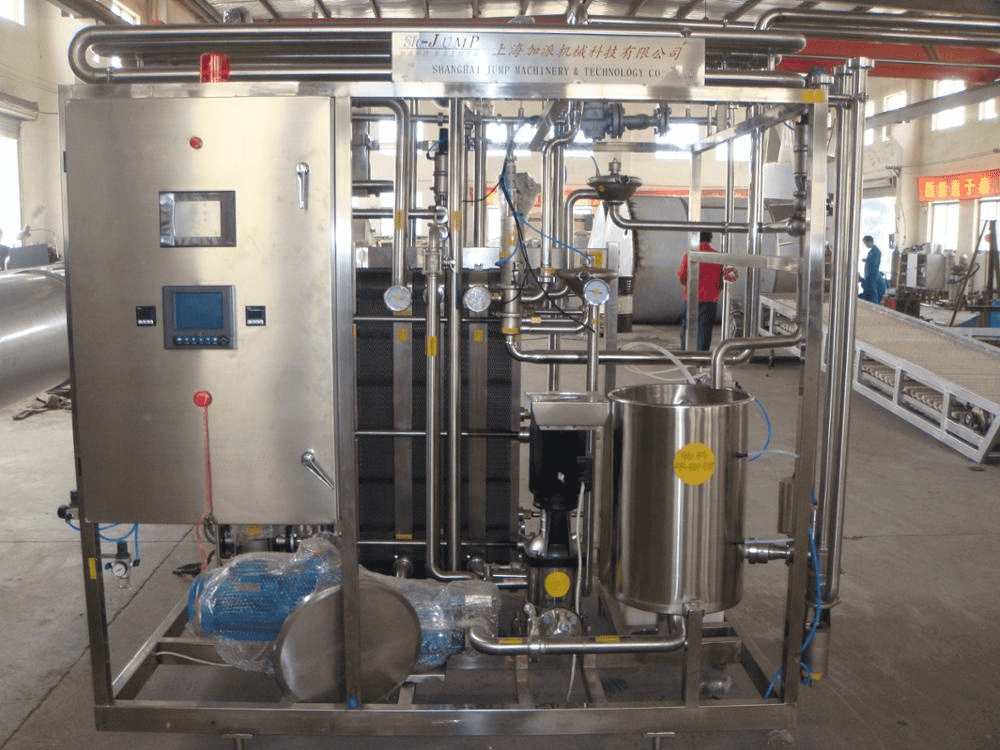

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Original Factory Conditioning Equipment - Canned food machine and Jam production equipment – JUMP , The product will supply to all over the world, such as: Singapore, Guatemala, Morocco, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, be sure to click the button to acquire additional nformation.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.