OEM/ODM Supplier Peeling And Denudation Machine - Automatic Production Line For Sugarcane Juice Concentrate Making Machine – JUMP

OEM/ODM Supplier Peeling And Denudation Machine - Automatic Production Line For Sugarcane Juice Concentrate Making Machine – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JPF-DPL006

- Type:

-

production line for sugarcane juice

- Voltage:

-

380V/220V

- Power:

-

4kw

- Weight:

-

30TONS

- Dimension(L*W*H):

-

1180*680*1800

- Certification:

-

CE Certificate

- Warranty:

-

12 Months

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

production line for sugarcane juice

- Material:

-

Food Grade Stainless Steel 304

- Application:

-

Kinds of fruit beverage production line

- Name:

-

Extraction Machine

- Function:

-

Kinds of production line for fruit juice

- Usage:

-

Industrial Usage

- Capacity:

-

500 T/D

- Item:

-

No-pollution Food Dehydrator Machine

- Feature:

-

Turn key project

- Color:

-

silver

- Supply Ability:

- 8 Set/Sets per Month production line for sugarcane juice

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- Shanghai

- Lead Time :

- 60 days

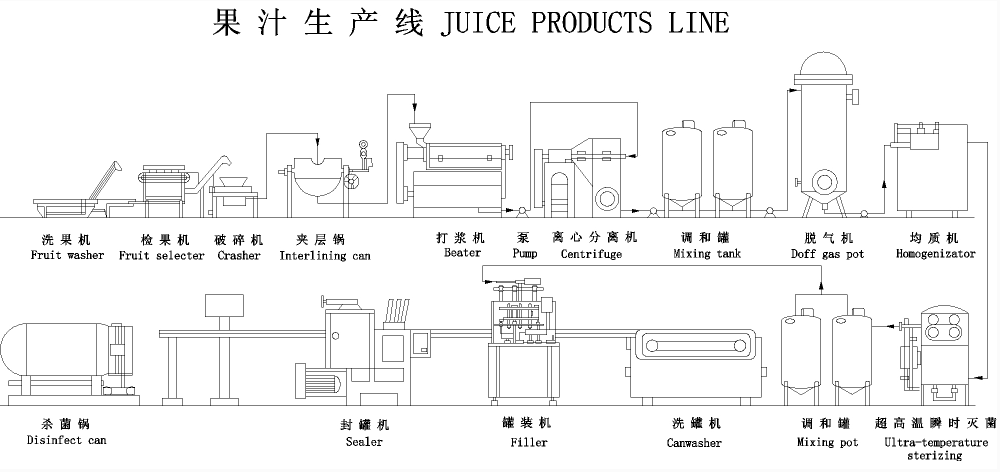

Production line for sugarcane juice

This machine has washing ,filling and capping three functions in one body, total process is automatic, and it is suitable for high temperature resistant PET bottled juice and tea drink filling, it applies advanced micro-pressure gravity type filling principle, with perfect re-circulation system, without contacting with material, avoid secondary pollution and oxidation. It is made of high quality SUS304 stainless steel,the material of parts inside of the filling valve must be SUS316 . Main components are processed precisely by CNC machine tools. The machine adopts advanced photo electricity to detect running status. No bottle no filling. It is possible to realize man-machine conversation because of applying touch screen for operation.

Main Features

PET Bottle Fruit Juice Liquid Filling Machine—-Main performance

●Bottle is entered by air conveyor, the speed of bottle entering is fast and bottle shape is not changed because of adopting hanging clamping bottleneck way.

●Adopting clamping bottleneck way to wash bottle mouth and avoiding touch screw mouth, adopting clamping bottleneck way in the whole conveying process. When bottle type changes, you need to change the board related with bottle diameter.

●Filling adopts cylinder feeding structure, filling valve adopts high filling speed and mass flow rate valve which control liquids level accurately and without loss.

●The capping system applies advanced French technology, when clamp the cap will screw immediately and magnetic torque type capping head.

●Main PLC and frequency changer are used famous brand, such as Mitsubishi and Omron etc.

Select stainless steel bracket, food-grade and hard plastic or stainless steel scraper, smoothing blade architecture to prevent the fruit jam; Using imported anti-corrosion bearings, double-sided seal; with continuously variable transmission motor, variable frequency Speed and low operating costsTitle goes here.

Stainless steel roller conveyor, rotation and solution, a full range of check, no need ends. Manmade fruit platform, painted carbon steel bracket,stainless steel antiskid pedal,stainless steel fence.

C. Crusher and Pulp

Fusing Italian technology, multiple sets of cross-blade structure, crusher size can be adjusted according to customer or specific project requirements, it will increase the juice juice rate of 2-3% relative to the traditional structure , which is suitable for production of onion sauce, carrot sauce, pepper sauce , apple sauce and other fruits and vegetables sauce and products

D. Extractor

It have tapered mesh structure and the gap with load can be adjusted, frequency control, so that the juice will be cleaner; Internal mesh aperture are based on customer or specific project requirements to order

E. Evaporator

Single-effect, double-effect,triple-effect and multi-effect evaporator, which will save more energy; Under vacuum, continuous low temperature cycle heating to maximize the protection of nutrients in the material as well as the originals. There are steam recovery system and double times condensate system, it can reduce the consumption of steam;

F. Sterilization machine

Having obtained nine ed technology, take full advantages of the material’s own heat exchange to save energy– about 40%

F. Filling machine

Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return; Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ; In the filling process,using turntable lifting mode to avoid secondary pollution.

Packing.

1) Tin packing as 70g, 198g,210g,400g,800g,850g,1kg, 2.2kg,3kg,4.5kg.

Brix: 28/30% & 22/24% & 18/20%

Lable: Lithographic label & Paper label

Tins: Easy open & Normal

2) Drum packing in 220 LITERS ASEPTIC BAG IN IRON DRUMS.

4 DRUMS/PALLET,TOTAL 80 DRUMS IN 20FCL; TOTAL NET WIGHT IS 19MT/20′FCL.

Brix: 36/38% & 30/32% & 28/30%

Process under both Cold break & Hot break

With high A/B Value and low HMC value.

3) Wooden bin packing in 1300 LITERS ASEPTIC BAG IN wooden bin.

TOTAL 16 wooden bin IN 20FCL; TOTAL NET WIGHT IS 20MT/20′FCL.

Brix: 36/38% & 30/32% & 28/30%

Delivery.

1. Time of Shipment : Shipped within 15 days after receiving the deposits and confirming the labels and carton marks

2. Terms of Payment: By T/T 30% of total amount in advance ,the balance upon receipt of copy of original B/Lwithin 7 days.

3. Port of Loading: Tianjin port.China

4.Delivery lead time: 30-30days

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup

Product detail pictures:

Related Product Guide:

We love an incredibly fantastic standing amid our consumers for our superb item high quality, aggressive rate and also the finest assistance for OEM/ODM Supplier Peeling And Denudation Machine - Automatic Production Line For Sugarcane Juice Concentrate Making Machine – JUMP , The product will supply to all over the world, such as: Singapore, Vietnam, Bangladesh, Ensuring high product quality by choosing the best suppliers, now we have also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.