OEM manufacturer Gum Based Candy Production Line - Repacking Double Concentrated 28-30% Tomato Sauce Processing Line – JUMP

OEM manufacturer Gum Based Candy Production Line - Repacking Double Concentrated 28-30% Tomato Sauce Processing Line – JUMP Detail:

- Place of Origin:

-

Xinjiang, China

- Brand Name:

-

OEM

- Model Number:

-

pouch tomato sauce

- Brix (%):

-

5 %

- Primary Ingredient:

-

Tomato

- Taste:

-

Natural

- Weight (kg):

-

25 kg

- Additives:

-

100% Pure

- Packaging:

-

Bag, bottle, Box, Bulk, Can (Tinned), DRUM, Mason Jar, Sachet, Vacuum Pack, stand-up pouch

- Certification:

-

HACCP, ISO, KOSHER, QS

- Shelf Life:

-

1 Year

- Type:

-

Pastry Sauce

- Form:

-

Pasty

- Product Type:

-

Canned Vegatables

- Packing:

-

220 L aseptic bag in drums

- Product:

-

HALAL tomato paste

- Color:

-

Natural Red

- Raw Material:

-

100% Fresh Ripe Tomatoes

- Processing Type:

-

Cold Break Hot Break

- Similar series:

-

Tomato Chili Sauce

- Supply Ability:

- 10 Set/Sets per Year specification tomato sauce

- Packaging Details

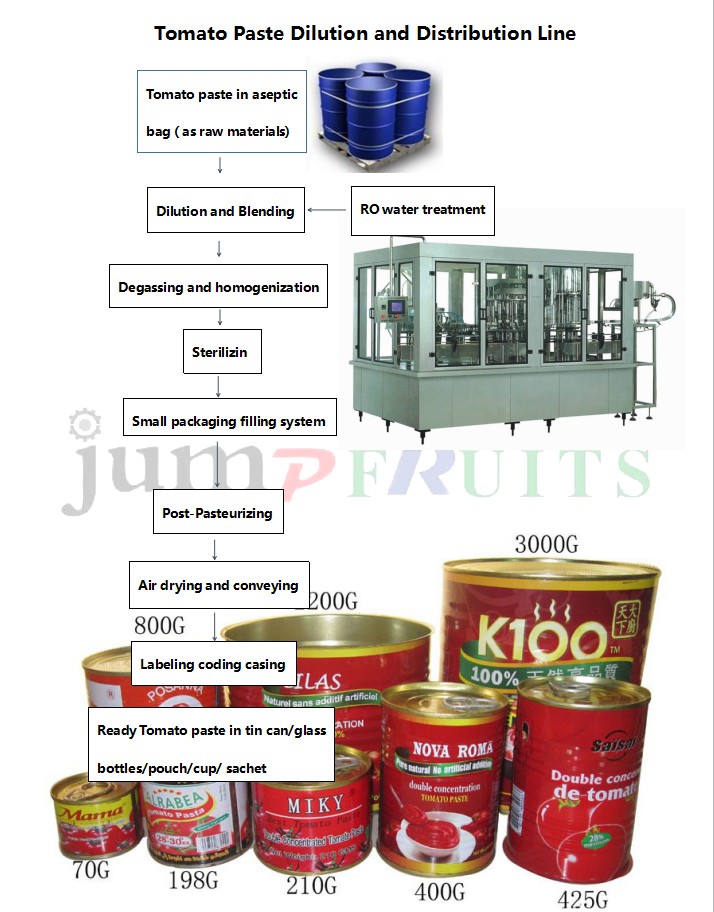

- 1) Tin packing as 70g, 198g,210g,400g,800g,850g,1kg, 2.2kg,3kg,4.5kg in cartons.2) Flat sachet packing as 40g, 50g, 56g,70g; Stand-up sachet packing 50g, 56g, 70g, 140g, 200g, 400g. 3) Drum packing in 220 liters aseptic bag in drums.4) Wooden bin packing in 1300 liters aseptic bag in wooden bin.Mobile/whatsapp:+8618018520615

- Port

- Tianjin

specification of our varities packages of tomato sauce.

Stand-up sachet packing 50g, 56g, 70g, 140g, 200g, 400g.

3) Drum packing in 220 liters aseptic bag in drums.

4) Wooden bin packing in 1300 liters aseptic bag in wooden bin.

Package Type:

Conical drum: 220L steel drum for outer packing,55 Gallon aseptic bag with plastic bag outer for inner packing.

220L BULK PACKAGE TOMATO PASTE

BRIX 28-30%, 30-32%, 36-38

Commodity: 28-30% cold break tomato paste.

A/B color: 2.2min

pH: 4.0-4.5

HMC: 48 max

Bosytwick: 4.0-10. Cm/30sec.

Lycopene: 50mg/100g min

PACKAGE BY 220L STEEL DRUM

80drums/20ft continer.

Ingredient: 100% fresh & nature tomatoes

Shelf time: 2 years

Storage: In clearn, dry and ventilated area.

Quality control under HACCP, ISO, QS.

CANNED TOMATO PASTE

Brix: 28-30%, 22-24%, 18-20%

Lithographic Label & paper Label

Normal lid & easy open lid

1.70g× 100cans/CTN

Quantity /20′FCL: 2350 cartons

2.210g× 48cans/CTN

Quantity /20′FCL: 1850cartons

3.400g× 24cans/CTN

Quantity /20′FCL: 1980 cartons

4.800g× 12cans/CTN

Quantity /20′FCL: 1950 cartons

5.850g× 12cans/CTN

Quantity /20′FCL: 1900 cartons

6. 2.2kg× 6cans/CTN

Quantity /20′FCL: 1560 cartons

7.3.0kg× 6cans/CTN

Quantity /20′FCL: 1000 cartons

8. 4.5kg× 6cans/CTN

Quantity /20′FCL: 750 cartons

Welcome OEM, your private label

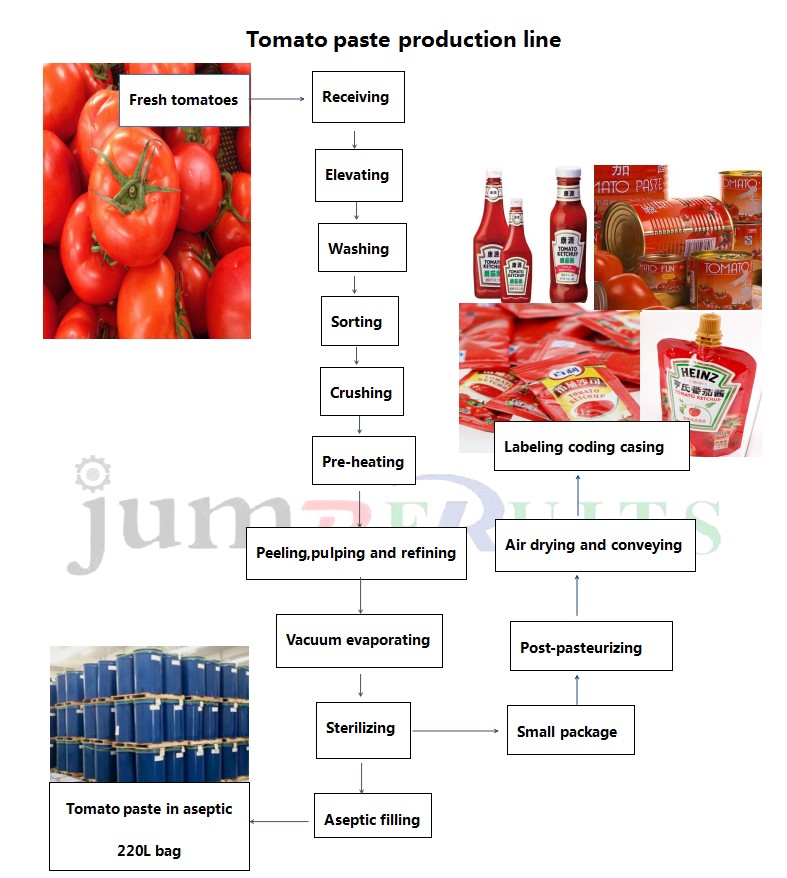

A: promotion system of the original fruits, cleaning system, sorting system, crushing system, pre-heating sterilization system, pulping system, vacuum concentration system, sterilization system, aseptic bag filling system

B: pump → blending drum → homogenization →deaerating → sterilization machine → washing machine → filling machine → capping machine → tunnel spray sterilizer → dryer → coding → boxing

3. The final product concentration: Brix 28-30%, 30-32% cold broken and heat broken, 36-38%

Packing.

1) Tin packing as 70g, 198g,210g,400g,800g,850g,1kg, 2.2kg,3kg,4.5kg.

Brix: 28/30% & 22/24% & 18/20%

Lable: Lithographic label & Paper label

Tins: Easy open & Normal

2) Drum packing in 220 LITERS ASEPTIC BAG IN IRON DRUMS.

4 DRUMS/PALLET,TOTAL 80 DRUMS IN 20FCL; TOTAL NET WIGHT IS 19MT/20′FCL.

Brix: 36/38% & 30/32% & 28/30%

Process under both Cold break & Hot break

With high A/B Value and low HMC value.

3) Wooden bin packing in 1300 LITERS ASEPTIC BAG IN wooden bin.

TOTAL 16 wooden bin IN 20FCL; TOTAL NET WIGHT IS 20MT/20′FCL.

Brix: 36/38% & 30/32% & 28/30%

Delivery.

1. Time of Shipment : Shipped within 15 days after receiving the deposits and confirming the labels and carton marks

2. Terms of Payment: By T/T 30% of total amount in advance ,the balance upon receipt of copy of original B/Lwithin 7 days.

3. Port of Loading: Tianjin port.China

4.Delivery lead time: 30-30days

1. What’s your payment terms?

T/T or L/C.

2. What’s your delivery time?

Usually we will arrange the shipment in 7 -20days

3. How about the packing?

Usually we provide the packing as 25 kg / bag or carton. Of course, if you have special requirements on them, we will according to you.

4. How about the validity of the products?

According to the products you ordered.

5. What documents you provide?

Usually, we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for OEM manufacturer Gum Based Candy Production Line - Repacking Double Concentrated 28-30% Tomato Sauce Processing Line – JUMP , The product will supply to all over the world, such as: Iraq, Mumbai, belarus, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!