OEM Factory for Fruit Powder Production Line - Full-automatic Capactity 500kg-10t/h Coconut Juice / Milk Processing Plant – JUMP

OEM Factory for Fruit Powder Production Line - Full-automatic Capactity 500kg-10t/h Coconut Juice / Milk Processing Plant – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

OEM

- Model Number:

-

JUMP-FQJL

- Type:

-

PROCESSING LINE

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

80 TONS

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

ISO 9001,CE

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

fruit juice production line

- Material:

-

304 Stainless Steel

- Name:

-

coconut processing plant

- Application:

-

Kinds

- Function:

-

Multifunctional

- Usage:

-

Industrial Usage

- Capacity:

-

500kg/h of fresh fruits

- Item:

-

Thickness Adjustable

- Feature:

-

Turn Key

- Color:

-

Silver

- Supply Ability:

- 3 Set/Sets per Month coconut juice machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- shanghai

- Lead Time :

- 60 days

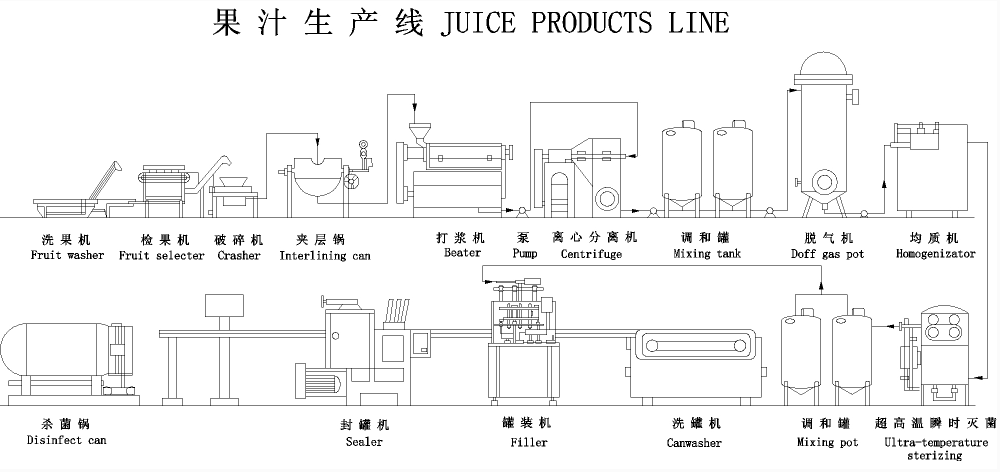

Coconut Juice Production Line

Shanghai Jump Automatic Equipments CO., LTD., specializing in the production of fruit juice, jam processing equipment, after many years of practical experience, combined with foreign advanced technology and technology, especially the Italian juice jam processing technology, this company has formed the unique style, in the high-end configuration technology, mastered the core technology of the whole production line, including cold, hot breaking temperature control, improving pulper pulp yield limit, concentrated pot on the basis of the original more energy efficient, filling machine sterile environment live and stainless steel connection incomparable technical advantage has made the domestic enterprises.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Main Features

Name: Evaporator

Brand: Jump

Original: Italy

Specially for the fruit paste ,syrup and other high-viscosity products. Continuous low-temp evaporation under vacuum to ensure the least loss of the efficient substance insides. Incorporated Italian technology and made as per Europe stand. Have more experienced in producing the unit. More than 70 lines in china and world wide run smoothly. The processing

capacity ranging from 300L-35000L water evaporated per hour by means of single effect or double effect or triple effect vacuum evaporator

The unit is composed of tubular heater, vacuum evaporation chamber, multi-stage condenser, pumps, PLC control system, valves, meters& gauges, operation platform, etc.

Compacted structure,stable running,high efficiency and energy-saved performance.

Machine Parts

Name: Tube Sterilizer

Brand: Jump

Original: China

Suitable for sterilizing and cooling of concentrate products. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

Four layer concentric tubular structure,the inner two layers and outside layer go through heat exchange medium and the middle for the product to maximize the heat exchanging area and efficiency,make the temperature even and then thoroughly sterilize the product

Great heat exchange area, low energy consumption and easy maintenance. Adopt mirror welding tech and keep the smooth pipe joint. Auto backtrack if not enough sterilization

CIP and auto SIP available together with aseptic filler

Main Features

Name: Bucket elevator

Brand: Jump

Original: China

Suitable for the low or high level lifting of tomato paste, jerusalem artichoke,strawberry,apple,pear, apricot etc. With spray washing.

Smooth bucket structure against clamping fruits, and water-penetrate structure to discharge water on the surface of fruit;chain drive,running stably with low noise, speed adjustable by transducer. Anticorrosive bearings, double sides seal.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.

<!– tangram:4

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for OEM Factory for Fruit Powder Production Line - Full-automatic Capactity 500kg-10t/h Coconut Juice / Milk Processing Plant – JUMP , The product will supply to all over the world, such as: Austria, Indonesia, Atlanta, At present our sales network is growing continually, improving service quality to meet customer's demand. If you are interested in any products , please contact us at anytime. We are looking forward to forming successful business relationships with you in near future.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!