OEM Factory for Condensed Milk Processing Machine - Carbonated beverage and soda drink prodution machine – JUMP

OEM Factory for Condensed Milk Processing Machine - Carbonated beverage and soda drink prodution machine – JUMP Detail:

Carbonated drinks, the main ingredients include: carbonated water, citric acid and other acidic substances, sugar, spices, some contain caffeine, artificial colors, etc. In addition to carbohydrates can supplement energy to the human body, aerated “carbonated drinks” contain almost no nutrients. The common ones are: coke, Sprite and soda.

Carbon drink machines or Coke machines. It is the main machine and equipment for making carbonated beverage. Carbonated beverage machine includes Bib syrup pump and joint, pressure gauge group, syrup pipeline and installation accessories, water filter, carbon dioxide cylinder, etc. Carbonated drinks generally like to combine with ice in the process of use. They are made by filling carbon dioxide into liquid drinks. The main components are sugar, pigment, spices, etc.

The production process of carbonated beverage can be divided into one filling method and two filling method.

Carbonated beverage and soda drink prodution machine one time filling method

It is also known as pre conditioning filling method, finished product filling method or pre mixing method. The flavoring syrup and water are pumped into the carbonated beverage mixer according to a certain proportion in advance, and then cooled after quantitative mixing, and then the mixture is carbonated and then put into the container.

Drinking water → water treatment → cooling → gas water mixing ← carbon dioxide

Syrup → blending → mixing → filling → sealing → inspection → product

Container → cleaning → inspection

PET bottle carbonated beverage production equipment adopts the bottle neck drive technology to realize automatic bottle washing, filling, capping and other processes, with high degree of automation; it is equipped with accurate CO2 pressure control and stable liquid level control; it is equipped with multiple protection alarm devices such as bottle jam, bottle missing, cap missing and overload to ensure the product quality; it has the advantages of high reliability, high efficiency and easy operation. The parts in contact with the materials of the carbonated beverage filling machine are made of stainless steel, which is sanitary and easy to clean.

|

MODEL |

JMP16-12-6 |

JMP18-18-6 |

JMP24-24-8 |

JMP32-32-10 |

JMP40-40-12 |

JMP50-50-15 |

|

Washing head |

16 |

18 |

24 |

32 |

40 |

50 |

|

Filling head |

12 |

18 |

24 |

32 |

40 |

50 |

|

Capping head |

6 |

6 |

8 |

10 |

12 |

15 |

|

Capacity |

3000BPH |

5000BPH |

8000BPH |

12000BPH |

15000BPH |

18000BPH |

|

Power(KW) |

3.5 |

4 |

4.8 |

7.6 |

8.3 |

9.6 |

|

Outside(mm) |

2450X1800X2400 |

2650X1900X2400 |

2900X2100X2400 |

4100X2400X2400 |

4550X2650X2400 |

5450X3210X2400 |

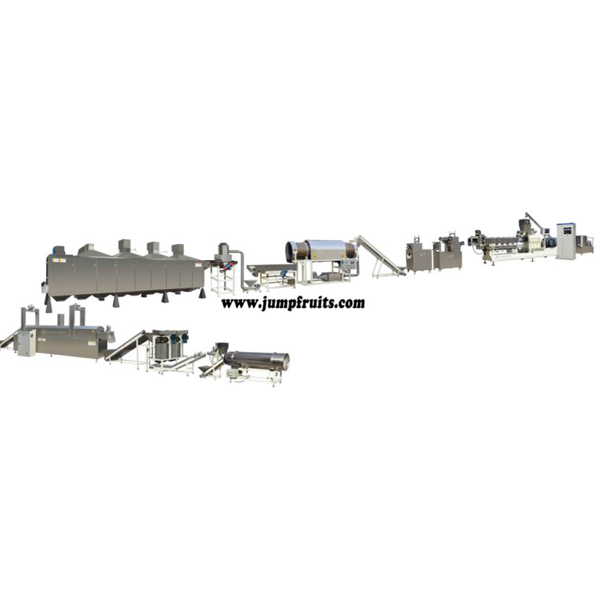

Product detail pictures:

Related Product Guide:

While using the "Client-Oriented" company philosophy, a demanding high-quality management method, innovative producing products and also a sturdy R&D workforce, we always deliver premium quality merchandise, superb solutions and aggressive selling prices for OEM Factory for Condensed Milk Processing Machine - Carbonated beverage and soda drink prodution machine – JUMP , The product will supply to all over the world, such as: Kuala Lumpur, Nicaragua, Poland, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!