1 Used to wash fresh tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

OEM Customized Canned Soybeans Processing Machine - Ginger Garlic Paste Production Line / Garlic Paste Making Machine – JUMP

OEM Customized Canned Soybeans Processing Machine - Ginger Garlic Paste Production Line / Garlic Paste Making Machine – JUMP Detail:

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

1 Year

- Core Components:

-

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

OEM

- Type:

-

turn-key project

- Voltage:

-

220V/380V

- Power:

-

2.2kw

- Weight:

-

150kg

- Dimension(L*W*H):

-

1380*1200*2000mm

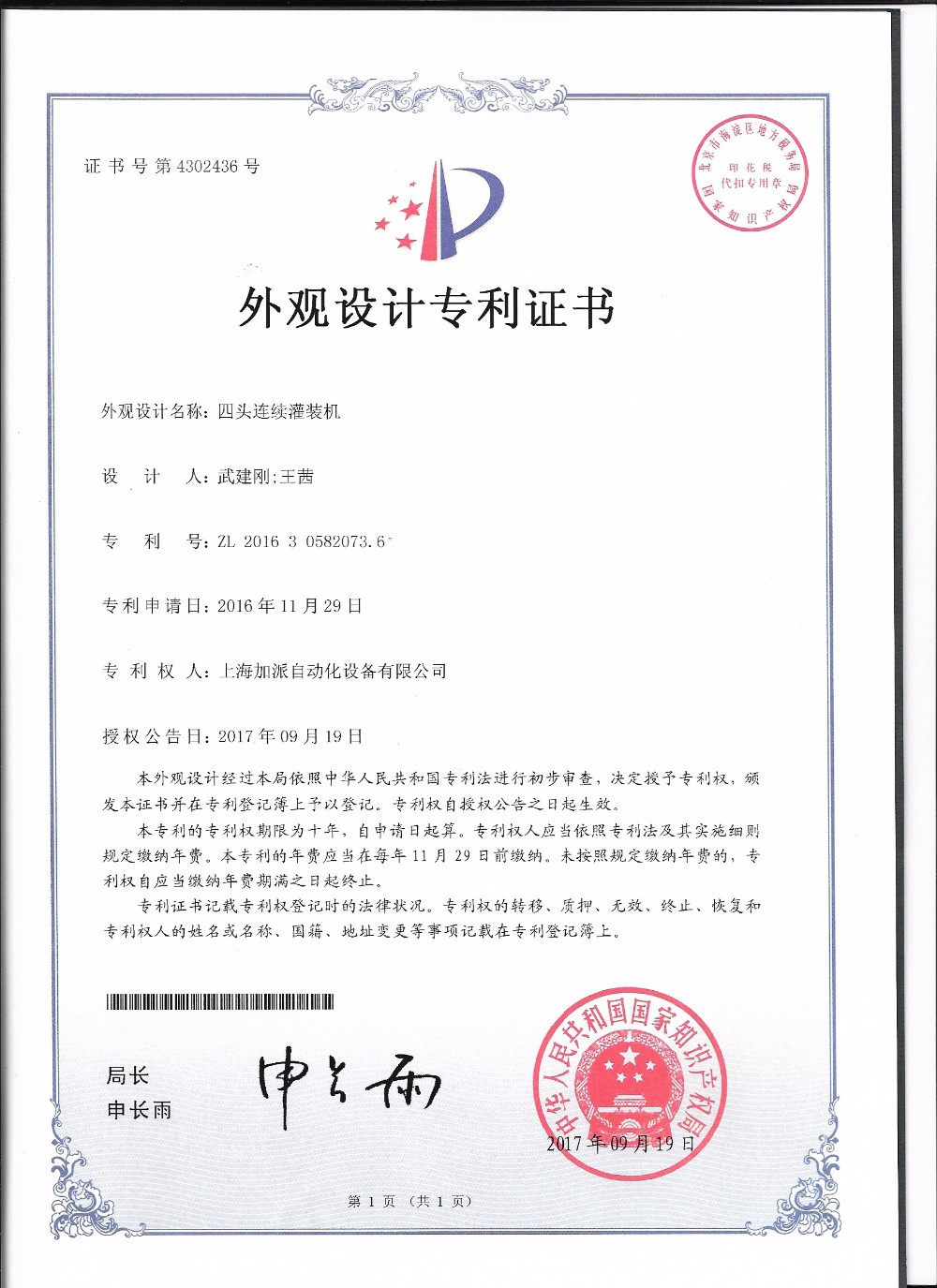

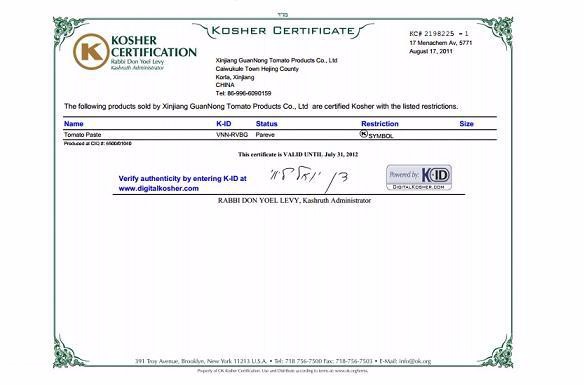

- Certification:

-

CE ISO

- Warranty:

-

2 Years, 1 Years

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

ginger garlic paste production line

- Function:

-

Multifunctional

- Material:

-

Stainless Steel 304

- Application:

-

ginger garlic

- Capacity:

-

3-10t/h

- Usage:

-

Industrial Usage

- Feature:

-

High Efficiency

- Color:

-

Customers’ Requirements

- Supply Ability:

- 10 Set/Sets per Month

- Packaging Details

- package in carton

- Port

- Shanghai

ginger garlic paste production line/garlic paste making machine

Air Blowing & Washing Machine

Peeling, pulping & Refining Monobloc (Pulper)

1. The unit can peel, pulp and refine fruits together.

2. The aperture of strainer screen can be adjustable (change) based on customer’s requirement.

3. Incorporated Italian technology, high quality stainless steel material in contact with fruit material.

Belt press extractor

1. Widely used in extracting and dehydrating of many kinds of acinus, pip fruits, and vegetables.

2. the unit adopt advanced technology, big press and high efficiency, high degree of automatic, easy to operate and maintains.

3. the extraction rate can be get 75-85%(based on raw material)

4. low investment and high efficiency

Preheater

1. To inactivate enzyme and protect color of paste.

2. Auto temperature control and the out temperature are adjustable.

3. Multi-tubular structure with end cover

4. If the effect of preheat and extinguish enzyme failed or not enough, the product flow return to tube again automatically.

Evaporator

1. Adjustable and controllable direct contact heat treatment units.

2. Shortest possible residence time, presence of a thin film along the entire length of the tubes reduces holdup and residence time.

3. Special design of liquid distribution systems to ensure correct tube coverage. The feed enters at the top of the calandria where a distributor ensures film formation on the inside surface of each tube.

4. The vapor flow is co-current to the liquid and the vapor drag improves the heat transfer. The vapor and the remaining liquid are separated in a cyclone separator.

5. Efficient design of separators.

6. Multiple effect arrangement provides steam economy.

Tube in tube sterilizer

1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

2. Incorporated Italian technology and conform to Euro-standard

3. Great heat exchange area, low energy consumption and easy maintenance

4. Adopt mirror welding tech and keep the smooth pipe joint

5. Auto backtrack if not enough sterilization

6. CIP and auto SIP available together with aseptic filler

7. Liquid level and temp controlled on real time

Pre-sales service

We can suggest customer the most suitable machine according to their formula and Raw material. “Design and development”, “manufacturing”, “installation and commissioning”, “technical training” and “after sales service”. We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

After-sale service

1.Installation and commissioning: We will send experienced engineering and technical personnel to be responsible for the installation and commissioning of the equipment until the equipment is qualified to ensure that the equipment is in time and put into production;

2.Regular visits:To ensure the long-term stable operation of the equipment, we will be based on customer needs, provide one to three times a year to come to technical support and other integrated services;

3.Detailed inspection report: Whether the inspection regular service, or the annual maintenance, our engineers will provide a detailed inspection report for the customer and the company reference archive, in order to learn the equipment operation at any time;

4.Fully complete parts inventory: In order to reduce the cost of parts in your inventory, provide better and faster service, we prepared a complete inventory of parts of equipment, to meet customers possible period of want or need;

5.Professional and technical training:In order to ensure the performance of the customer’s technical personnel to become familiar with the equipment, correctly grasp the equipment operation and maintenance procedures, in addition to install on-site technical training. Besides, you also can hold all kinds of professionals to the factory workshops, to help you faster and more comprehensive grasp of technology;

6.Software and consulting services:In order to allow your technical staff to have a greater understanding of the equipment related counseling, I will arrange to send the equipment regularly sent to the advisory and latest information magazine.No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Why choose us?

1.”Quality is priority”. we always attach great importance to quality control from the very beginning to the very end;

2.we have a professional manufacture experience and machining equipment;

3.we are factory ,we can provide you the super quality and very competitive price;

4.company has a quality,young,innovative and strong scientific research technical team

Is your price competitive?

surely we will give you best factory price based on superior product and service.

Any warranty?

1.one year equipment warranty after successful installation & commissioning of equipment and maintenance for lifelong time;

2.free installation and test before sending and free training for operation

3.advice for the solutions best for customers requirements

How about the test running & installation?

1.Before delivery, we finish the test over 3 times.

2.If you take integral design, no need to installation at all. If parted design, we can send our technicians to your place if necessary.

How to choose your wanted type?

1.tell us your requirement of the productivity.

2.You know about our machines ,the just tell us the type.

3.Give us the detailed information about your raw material,Picture will be best

beverage bottling

100% Response Rate

tomato paste production line

Product detail pictures:

Related Product Guide:

We always get the job done being a tangible workforce making sure that we can easily give you the very best quality as well as finest selling price for OEM Customized Canned Soybeans Processing Machine - Ginger Garlic Paste Production Line / Garlic Paste Making Machine – JUMP , The product will supply to all over the world, such as: Tanzania, French, Czech Republic, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!