As the global beverage market increasingly embraces natural, additive-free, and health-focused trends, 100% NFC juice has become a new benchmark for premium juice products. For juice brands and procurement professionals, understanding this category and selecting the right processing equipment—namely the NFC juice machine—is crucial for market positioning and competitive advantage.

Defining 100% NFC Juice in the Industry

NFC, short for Not From Concentrate, refers to juice that is extracted directly from fresh fruit and has not undergone the concentration and reconstitution process. 100% NFC juice is minimally processed: it is gently pasteurized for safety but contains no added water, sugar, or artificial ingredients.

Unlike traditional juice made from concentrate, NFC juice retains the fruit's original taste, aroma, color, and nutritional value. This positions it as a premium product, increasingly favored by high-end retailers, hotel chains, wellness brands, and functional beverage producers.

Growing Market Demand for NFC Juice

Driven by consumer health awareness and demand for transparency, the market share for NFC juice has been rising year over year. Labels such as “100% natural,” “cold-pressed,” and “no additives” are now common on packaging, signaling the product’s alignment with the clean label movement.

To meet this demand, more manufacturers are upgrading from concentrate-based production methods to dedicated NFC juice production lines, allowing them to offer higher-value products and tap into premium price segments.

The Role of NFC Juice Machines in High-Quality Production

To deliver consistent, high-quality NFC juice, producers rely on advanced NFC juice machines. These systems are engineered specifically for the non-concentrate juice segment and are ideal for processing a wide variety of fruits while maintaining freshness and maximizing yield.

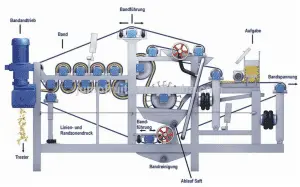

Modern NFC juice machines typically feature:

Cold press extraction: Preserves enzymes, vitamins, and antioxidants through low-temperature pressing

Automated processing systems: Integrates washing, peeling, pressing, filtering, mild pasteurization, and packaging into one efficient Not From Concentrate juice production line

High reliability for commercial production: Capable of continuous operation for industrial-scale juice facilities

Modular design: Easily adapted for different fruit types and production capacities

These features make NFC juice machines an essential investment for manufacturers aiming to upgrade their technology and enter the high-end juice market.

Strategic Value for Buyers and Procurement Teams

For procurement professionals in the beverage industry, choosing the right commercial NFC juice machine impacts more than just operational efficiency—it defines your product quality and market appeal.

Leading juice brands are investing in cold press juice equipment to create product lines with unique flavor profiles and clean labels. Integrating filling and packaging systems further automates the process, ensuring every bottle meets food-grade safety standards.

How NFC Juice Enhances Brand Value

In practice, a fully integrated NFC juice processing line supports brand development from the inside out. From raw fruit handling to finished packaging, this streamlined process reinforces the brand’s core promise of freshness, purity, and authenticity.

Whether you are sourcing equipment for a new facility or upgrading your current line, factors such as machine hygiene, nutrient retention, and ease of maintenance should be top priorities in selecting an NFC juice machine.

100% NFC juice is redefining the premium juice landscape. As consumer preference shifts toward cleaner, more natural beverages, manufacturers must respond by upgrading their capabilities. Investing in modern NFC juice equipment and building a dedicated non-concentrate processing line not only improves product quality but also positions your brand for long-term growth.

In today’s competitive market, NFC juice technology is more than just a tool—it’s a strategic investment.

Post time: May-13-2025