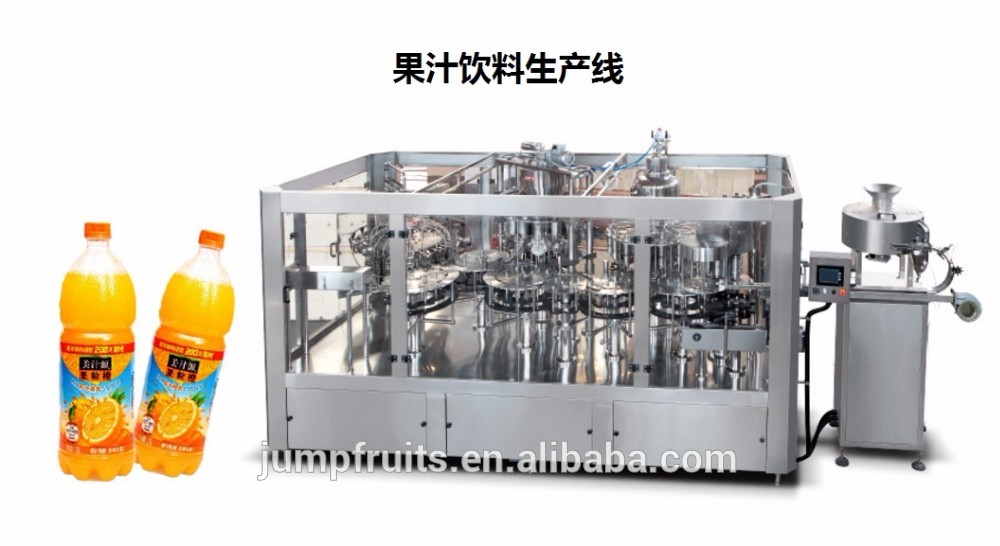

Manufactur standard Coke Equipment - Sugarcane Juicer Machinery Production Line – JUMP

Manufactur standard Coke Equipment - Sugarcane Juicer Machinery Production Line – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

OEM

- Model Number:

-

JP-GZ003

- Type:

-

processing line

- Voltage:

-

380V

- Power:

-

2.2kw

- Weight:

-

300kg

- Dimension(L*W*H):

-

1560*450*1340mm

- Certification:

-

ISO

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

Sugarcane juicer machinery production line/plant

- Function:

-

Extracting

- Usage:

-

Industrial Usage

- Application:

-

fruits vegetables juice

- Capacity:

-

200-500kg/h

- Material:

-

304 Stainless Steel

- Item:

-

Automatic Fruits Juicer Machine

- Feature:

-

Turn Key Project

- Color:

-

Silver Grey

- Name:

-

Fruit juice production line/plant made in shanghai

- Supply Ability:

- 25 Set/Sets per Year automatic juicer extractor machine

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion. Fumigation-free package helps the smooth customs clearance. The big size machine will be fixed in container without package. Or accroding to your requirements

- Port

- SHANGHAI

- Lead Time :

- within 2 months

Automatic Juicer extractor machine

Our Advantages:

1.Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop services, from your warehouse designing(water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

2.15 years export experience, easily transport cargo to your door

3.customized service, we will try our best to meet your requirement.

4.Quality guarantee: 12 months. After that, engineers also available on your traval expense and spare parts cost.We offer life-long after-sale service.

Main advantages of our system line:

1. High production speed achieved by a newly designed head system (single head or twin heads available), improved reliability from a fully PLC controlled self diagnostic operational mode.

2. Greater versatility by meeting various packing standards with different products.

3 Coordinates well with the tube in tube sterilizer, if some malfunction with the filler, the product will be automatic flow back into the buffer tank before the UHT sterilizer.

4. The use of a hermetically sealed empty bag ensures the bag will remain sterile before it is filled.

5. High pressure saturated steam is used for sterilization of the fitment, cap and exposed portion of the filler prior to each filling cycle. NO CHEMICALS are required.

6. The sealing of the fill valve on the interior of the fitment keeps product completely away from the package sealing area.

7. The hermetic heat sealing of the fitment provides a tamper evident closure and a superior oxygen barrier.

8. The overall aseptic design of the filler allows uninterrupted. Operation throughout a complete tomato/fruit season, maximizing your plant’s efficiency

9. CIP and SIP available together with tube in tube sterilizer

Peeling, pulping & Refining Monobloc (Pulper)

1. The unit can peel, pulp and refine fruits together.

2. The aperture of strainer screen can be adjustable (change) based on customer’s requirement.

3. Incorporated Italian technology, high quality stainless steel material in contact with fruit material.

Preheater

.1. To inactivate enzyme and protect color of paste.

2. Auto temperature control and the out temperature are adjustable.

3. Multi-tubular structure with end cover

4. If the effect of preheat and extinguish enzyme failed or not enough, the product flow return to tube again automatically.

Evaporator

1. Adjustable and controllable direct contact heat treatment units.

2. Shortest possible residence time, presence of a thin film along the entire length of the tubes reduces holdup and residence time.

3. Special design of liquid distribution systems to ensure correct tube coverage. The feed enters at the top of the calandria where a distributor ensures film formation on the inside surface of each tube.

4. The vapor flow is co-current to the liquid and the vapor drag improves the heat transfer. The vapor and the remaining liquid are separated in a cyclone separator.

5. Efficient design of separators.

6. Multiple effect arrangement provides steam economy.

Tube in tube sterilizer

1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

2. Incorporated Italian technology and conform to Euro-standard

3. Great heat exchange area, low energy consumption and easy maintenance

4. Adopt mirror welding tech and keep the smooth pipe joint

5. Auto backtrack if not enough sterilization

6. CIP and auto SIP available together with aseptic filler

7. Liquid level and temp controlled on real time

Filling machine

1.Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return;

2.Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ;

3.In the filling process,using turntable lifting mode to avoid secondary pollution.

Welcome to contact us:

Contact person: Nancy Chen

Mobile/ wechat: +8618018520615

Website: www.jumpfruits.com

1.Professional engaged in whole plant equipment design, manufacturing, R & D and turnkey project for Fruit&vegetable deep processing ,Beverage Processing and Dairy Processing.

2.over fifteen years’ rich experience and sound technical strength.

3.more than 110 established fruit and vegetable processing production lines.

4.Has established stable technical cooperation with the Italy FBR, Ing. Rossi, Bertuzzi CFT.

5.We can provide the entire production line processing 20-1500 tons of raw fruit daily according to the customers

6.products are also widely infiltrated into overseas markets.

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.

Product detail pictures:

Related Product Guide:

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for Manufactur standard Coke Equipment - Sugarcane Juicer Machinery Production Line – JUMP , The product will supply to all over the world, such as: Madagascar, Albania, British, Our technical expertise, customer-friendly service, and specialized merchandise make us/company name the first choice of customers and vendors. We've been looking for your inquiry. Let's set up the cooperation right now!

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!