Manufactur standard Braised Canned Fish Processing Machine - Cold Break Brix 36%-38% Tomato Paste Concentrate System Tomato Jam Processing Line – JUMP

Manufactur standard Braised Canned Fish Processing Machine - Cold Break Brix 36%-38% Tomato Paste Concentrate System Tomato Jam Processing Line – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

Jump

- Model Number:

-

JK06RD

- Type:

-

Other

- Voltage:

-

220V/380V

- Power:

-

4kw

- Weight:

-

15000kg

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

CE ISO

- Warranty:

-

2 Years

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Production capacity:

-

0.5-500T/H

- Material:

-

SUS304

- Function:

-

whole processing line

- Usage:

-

ketchup, onion, carrot,chili, apples auce

- Raw material:

-

fresh tomato/fruit

- Advantage:

-

After-sales Service

- Supply Ability:

- 5 Set/Sets per Month

- Port

- shanghai ports

- Lead Time :

- 30-60days

Product Application

Raw materials: fresh tomato( mango, guayaba, papaya) but also can be shared with apricot sauce and chili sauce

The final product: paste, sauce, and fruits jam

Packing: 220L aseptic bag in drum and 70g-4500g tinplate cans or 10g-500g plastic bag

Fresh tomato treatment: 0.5-500 tons/hour of fresh fruits

Tomato paste output: 0.1-100 tons/hour of 28%-30% ,36%-38%tomato paste

Whatsapp/Line/Wechat/Mobile: 008613681836263 Welcome any inquiry!

Main Features

we take advantages of the comprehensive and technical cooperation with the Italian company partner, now in fruit processing, cold breaking processing, multi effect energy saving concentrated, sleeve type sterilization and aseptic big bag canning has made domestic and unmatched technical superiority. We can provide the entire production line processing 500KG-1500 tons of raw fruit daily according to the customers.

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of “Quality and Service Branding”, after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

Spray cleaning machine

Material: SUS304 Stainless Steel with Stainless steel Scraper lifting,

Functions: receiving,washing,lifting

Motor Power: 3KW

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

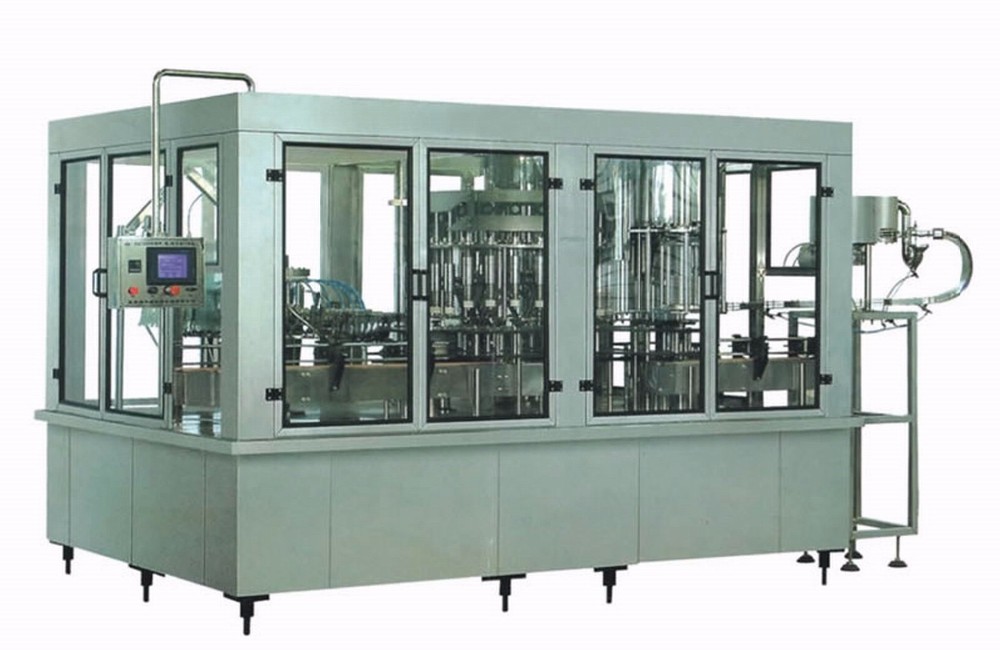

Filling maching

Specially suitable for tomato paste, mango puree and other viscous product.

35-50 bottle per min

Filling sachet valume:10-500g

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Product detail pictures:

Related Product Guide:

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for Manufactur standard Braised Canned Fish Processing Machine - Cold Break Brix 36%-38% Tomato Paste Concentrate System Tomato Jam Processing Line – JUMP , The product will supply to all over the world, such as: Brazil, Kuala Lumpur, Ottawa, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.