Hot-selling Hawthorn Jam Equipment - New Design Industrial Coconut / Almond / Soya Milk Processing Machine – JUMP

Hot-selling Hawthorn Jam Equipment - New Design Industrial Coconut / Almond / Soya Milk Processing Machine – JUMP Detail:

- Applicable Industries:

-

Food Shop

- After Warranty Service:

-

Online support

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Warranty of core components:

-

1 Year

- Core Components:

-

Engine

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Type:

-

processing line

- Voltage:

-

220V/380V

- Power:

-

2.2kw

- Weight:

-

2t

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

CE ISO

- Warranty:

-

12 Months

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Production capacity:

-

100kg-2T/H

- Material:

-

SUS304

- Function:

-

whole processing line

- Usage:

-

Dairy product production line

- After-sales Service:

-

overseas engineer service available

- Advantage:

-

life-long after-sales Service

- Name:

-

uht milk production line

- Product name:

-

uht milk production line

- Capacity:

-

3-5t/h

- Supply Ability:

- 10 Set/Sets per Month coconut milk machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.32.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- shanghai port

Product Description

process 1: Milk collection system

process 2: sterilization system

process 3: Storage system

process 4: filling system

process 5: water treatment and cleaning system

process 6: Steam boiler system

Introduction:

Pasteurized milk is one of the important process of processing, will extend the shelf life of milk.

Pasteurization temperature and time are very important factors must follow quality and shelf life of milk required for such precise requirements. Homogeneous, high-temperature short-time pasteurization temperature is usually 72-75 ℃, holding time of 15-20 seconds. Heat treatment required to kill undesirable microorganisms and must ensure that pathogens such products are not damaged.

Homogeneous object or to split the fat globules of fat globules in milk in a finely distributed state, and prevent the formation of cream layer. Can be all homogeneous, it can be partial. Partial homogenization method is very economical because you can use a small homogenizer.

Advantages:

1. Users can design special requirements

2. In the same production line can produce different end products

3. A short incubation time

4. Can be accurately added and mixed aromatic substances

5. high Yield, low loss

6. Application of high technology to save energy 20%

7. The entire production process monitoring systems

8. Image, intuitive display, print all process parameters

Whatsapp/Line/Wechat/Mobile: 008613681836263 Welcome any inquiry!

Main Features

we take advantages of the comprehensive and technical cooperation with the Italian company partner, now in fruit processing, cold breaking processing, multi effect energy saving concentrated, sleeve type sterilization and aseptic big bag canning has made domestic and unmatched technical superiority. We can provide the entire production line processing 500KG-1500 tons of raw fruit daily according to the customers.

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of “Quality and Service Branding”, after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

Detailed Images

UHT milk sterilizer machine

1 Capacity of plant: 2T-300T/D

2 Products type: 1 or 2 or more kinds.

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

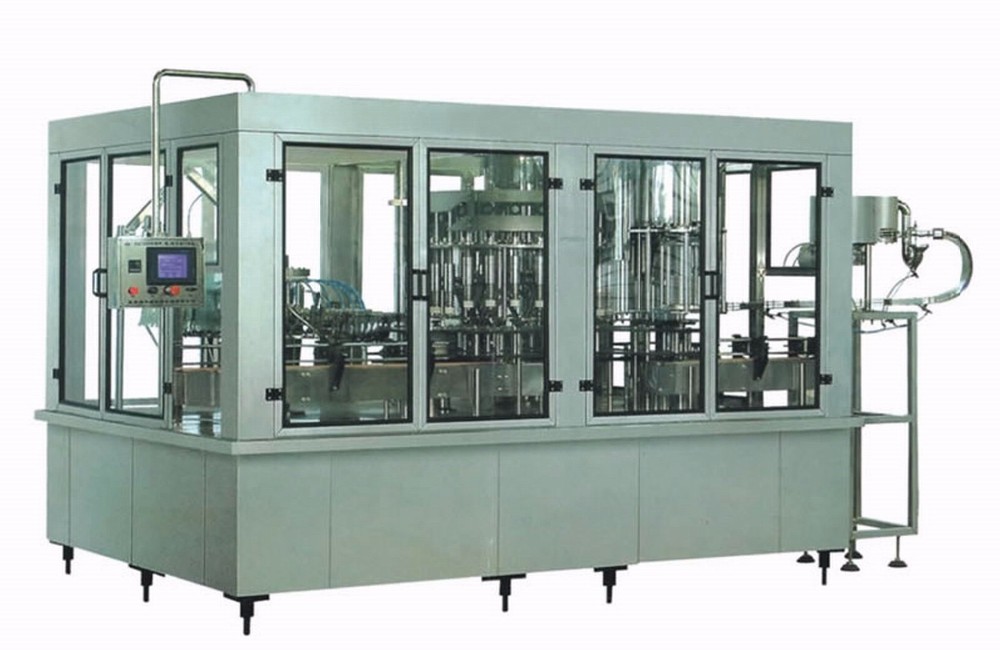

Filling maching

Specially suitable for tomato paste, mango puree and other viscous product.

35-50 bottle per min

Filling sachet valume:10-500g

Packing and Delivery

Final Products

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for Hot-selling Hawthorn Jam Equipment - New Design Industrial Coconut / Almond / Soya Milk Processing Machine – JUMP , The product will supply to all over the world, such as: Mauritania, Madagascar, Mauritius, We are looking forward to cooperating closely with you to our mutual benefits and top development. We guaranteed quality, if customers were not satisfied with the products' quality, you can return within 7days with their original states.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!