Fixed Competitive Price Three In One Filling Machine - Carbonated beverage and soda drink prodution machine – JUMP

Fixed Competitive Price Three In One Filling Machine - Carbonated beverage and soda drink prodution machine – JUMP Detail:

Carbonated drinks, the main ingredients include: carbonated water, citric acid and other acidic substances, sugar, spices, some contain caffeine, artificial colors, etc. In addition to carbohydrates can supplement energy to the human body, aerated “carbonated drinks” contain almost no nutrients. The common ones are: coke, Sprite and soda.

Carbon drink machines or Coke machines. It is the main machine and equipment for making carbonated beverage. Carbonated beverage machine includes Bib syrup pump and joint, pressure gauge group, syrup pipeline and installation accessories, water filter, carbon dioxide cylinder, etc. Carbonated drinks generally like to combine with ice in the process of use. They are made by filling carbon dioxide into liquid drinks. The main components are sugar, pigment, spices, etc.

The production process of carbonated beverage can be divided into one filling method and two filling method.

Carbonated beverage and soda drink prodution machine one time filling method

It is also known as pre conditioning filling method, finished product filling method or pre mixing method. The flavoring syrup and water are pumped into the carbonated beverage mixer according to a certain proportion in advance, and then cooled after quantitative mixing, and then the mixture is carbonated and then put into the container.

Drinking water → water treatment → cooling → gas water mixing ← carbon dioxide

Syrup → blending → mixing → filling → sealing → inspection → product

Container → cleaning → inspection

PET bottle carbonated beverage production equipment adopts the bottle neck drive technology to realize automatic bottle washing, filling, capping and other processes, with high degree of automation; it is equipped with accurate CO2 pressure control and stable liquid level control; it is equipped with multiple protection alarm devices such as bottle jam, bottle missing, cap missing and overload to ensure the product quality; it has the advantages of high reliability, high efficiency and easy operation. The parts in contact with the materials of the carbonated beverage filling machine are made of stainless steel, which is sanitary and easy to clean.

|

MODEL |

JMP16-12-6 |

JMP18-18-6 |

JMP24-24-8 |

JMP32-32-10 |

JMP40-40-12 |

JMP50-50-15 |

|

Washing head |

16 |

18 |

24 |

32 |

40 |

50 |

|

Filling head |

12 |

18 |

24 |

32 |

40 |

50 |

|

Capping head |

6 |

6 |

8 |

10 |

12 |

15 |

|

Capacity |

3000BPH |

5000BPH |

8000BPH |

12000BPH |

15000BPH |

18000BPH |

|

Power(KW) |

3.5 |

4 |

4.8 |

7.6 |

8.3 |

9.6 |

|

Outside(mm) |

2450X1800X2400 |

2650X1900X2400 |

2900X2100X2400 |

4100X2400X2400 |

4550X2650X2400 |

5450X3210X2400 |

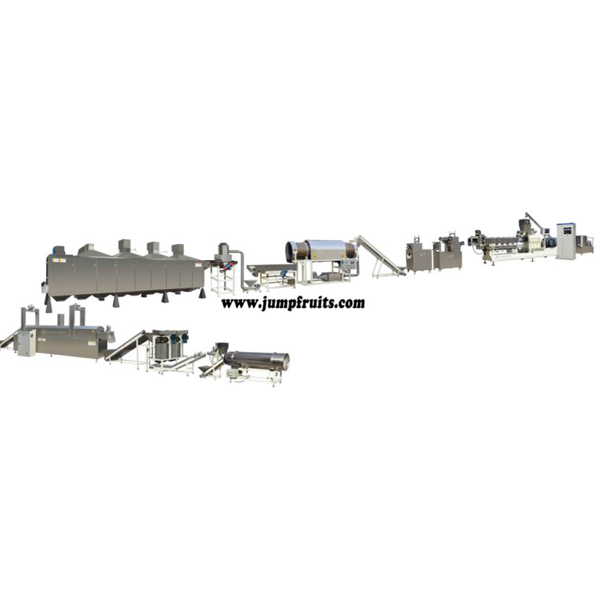

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of Fixed Competitive Price Three In One Filling Machine - Carbonated beverage and soda drink prodution machine – JUMP , The product will supply to all over the world, such as: Guinea, luzern, Detroit, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!