Factory wholesale Potato Chips Fryer - Automatic Canned Fruit Production Processing Line – JUMP

Factory wholesale Potato Chips Fryer - Automatic Canned Fruit Production Processing Line – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JPF-JZ001

- Type:

-

PROCESSING LINE

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

80 TONS

- Dimension(L*W*H):

-

1380*1200*2000mm

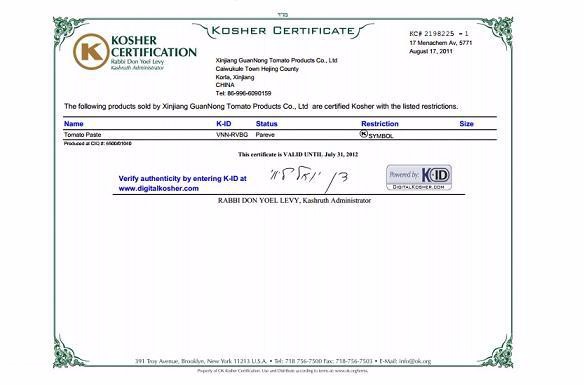

- Certification:

-

ISO 9001

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

Automatic canned fruit processing line

- Function:

-

Extracting

- Application:

-

Automatic canned mandarin orange plant

- Usage:

-

Industrial Usage

- Capacity:

-

2000-5000kg/h

- Item:

-

Automatic Fruits vegetables processing Machine

- Color:

-

Silver Grey or Customers’ Requirements

- Material:

-

304 Stainless Steel

- Feature:

-

Turn Key Project

- Name:

-

Automatic canned fruit processing line

- Supply Ability:

- 20 Set/Sets per Month

- Packaging Details

- carton box

- Port

- Shanghai,China

- Lead Time :

- 60 days

Raw material selection → Pre-treatment → Canning → Exhaust sealing → Sterilization and cooling → Insulation inspection → Package storage

The raw materials of fruits and vegetables generally have the following:

Bamboo shoots, mushrooms, peppers, ketchup, cucumbers, radishes, green beans, apples, pears, citrus, peaches, cherries, pineapples, etc.

Packaging: glass bottles, PET plastic bottles, cans, aseptic flexible packaging, roof bags, 2L-220L aseptic bags, carton packaging, plastic bags, 70-4500g tin cans.

Filling machine

1.Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return;

2.Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ; In the filling process,

3.Using turntable lifting mode to avoid secondary pollution.

Retort

1. Quick opendoor structure, safety interlock.

2. With compressed air pipe so as to be convenience for counter-pressure processing by customers.

3.The bowl shell is with insulation layer, which could reduce the energy consumption.

4. Control system—- Touch screen +PLC it automatically fulfill the whole process of exhausting, heatingup, cooling of counter pressure and drainage.

Tube in tube sterilizer

1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

2. Incorporated Italian technology and conform to Euro-standard

3. Great heat exchange area, low energy consumption and easy maintenance

4. Adopt mirror welding tech and keep the smooth pipe joint

5. Auto backtrack if not enough sterilization

6. CIP and auto SIP available together with aseptic filler

7. Liquid level and temp controlled on real time

A.Allotted for equipment inspection certificate and manual, to ensure that users properly install and use

B.Equipment to reach the destination, the company will send engineers to guide installation and commissioning and customer training until satisfied

C.The warranty period will be free to customers wearing accessories, shelf life outside of my company to provide parts at cost.

D. I provide lifelong maintenance service, including if necessary, to send engineers to the customer at the service.

Own tomato planting base in Xinjiang+Machinery processing line+15 years export experience+professional customerize service=your reliable business partner

1.Planting base in Xinjiang,producing tomato products(paste/powder,etc) in world top quality,with production capability of over 1000T/day

2.Factory of machinery and engineering vegetables and fruit paste processing,juice drink processing and fruit powder process etc.,absorbing world advanced technology.

3.15 years export experience, easily transport cargo to your door

4.customerized service, revise our products or OEM for your requirements

1. What’s your payment terms?

T/T or L/C.

2. What’s your delivery time?

Usually we will arrange the shipment in 1-2 months.

3. How about the packing?

Usually we provide the packing as carton. Of course, if you have special requirements on them, we will according to you.

4. What is loading port?

Usually is Shanghai.

5. What documents you provide?

Usually, we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.

6.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

7.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

8.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Factory wholesale Potato Chips Fryer - Automatic Canned Fruit Production Processing Line – JUMP , The product will supply to all over the world, such as: Buenos Aires, US, The Swiss, All styles appear on our website are for customizing. We meet up to personal requirements with all products of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.