Factory Outlets Thermosetting Bottle Machine - Yogurt Production Line / Milk Processing Plant – JUMP

Factory Outlets Thermosetting Bottle Machine - Yogurt Production Line / Milk Processing Plant – JUMP Detail:

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

5 years

- Core Components:

-

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

jumpfruits

- Voltage:

-

380v

- Power:

-

120kw

- Weight:

-

20t

- Dimension(L*W*H):

-

depends on capacity

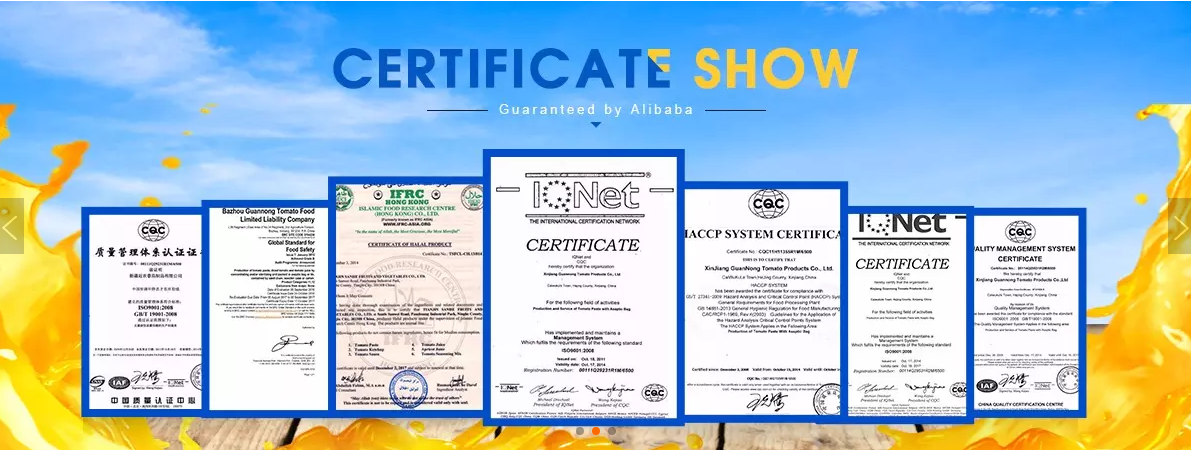

- Certification:

-

iso

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Field installation, commissioning and training

- Key Selling Points:

-

Easy to Operate

- Product name:

-

Yogurt Production Line

- Production capacity:

-

500kg-10 T/H

- Material:

-

SUS304

- Function:

-

steriling filling packing

- Usage:

-

Dairy product production line

- Feature:

-

turn key production project

- Application:

-

Milk Yogurt

- Raw material:

-

304

- Final product:

-

Yougurt

- Supply Ability:

- 10 Set/Sets per Month small yogurt processing plant

- Packaging Details

- standard export shipping standard.If you have your instruction,we will follow

- Port

- shanghai port

- Lead Time :

-

Quantity(Sets) 1 – 1 >1 Est. Time(days) 90 To be negotiated

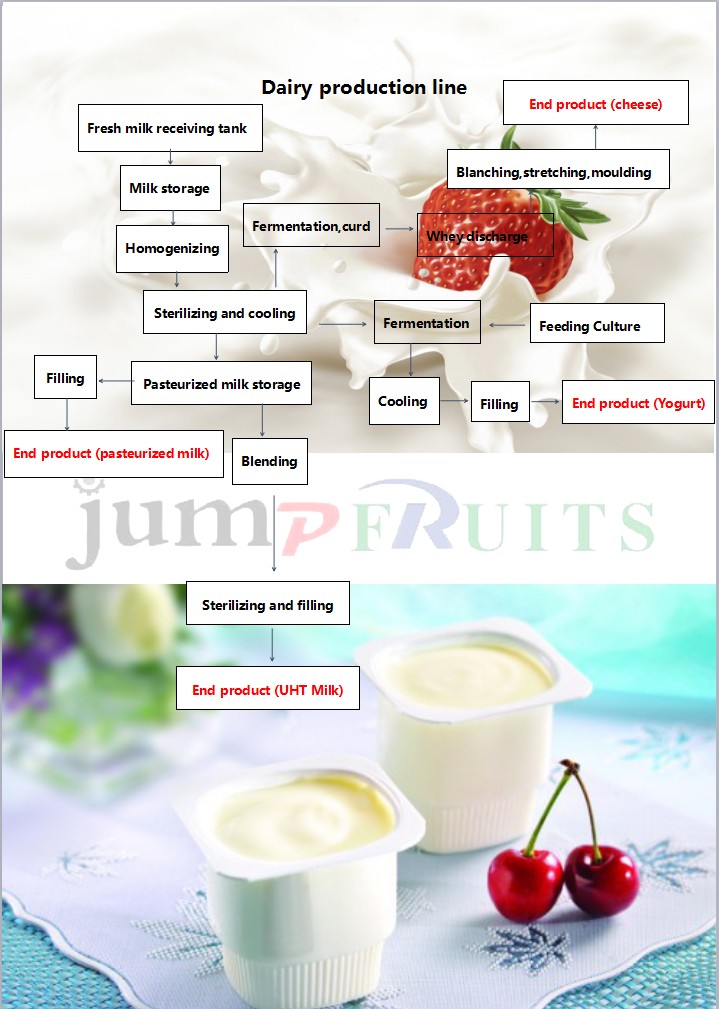

Fresh milk temporary storage → fresh milk net milk (net milk machine) → fresh milk cooling → fresh milk temporary storage → raw and auxiliary material mixing (high speed mixing tank) → liquid preheating (plate type sterilization machine) → material liquid homogenization (high pressure Homogenizer)→Pasteurization (tuber sterilization machine) → Insulation sterilization (insulation sterilization tube) → Liquid cooling (plate heat exchanger) → Strain input (yoghurt fermenter) → Insulation culture (yoghurt fermenter) →→ Fermentation termination (yoghurt fermenter)→semi-finished product cooling→temporary storage→aseptic mixing (semi-finished storage tank)→product packaging (fruit)→finished cold storage (shallow cold storage).

UHT milk sterilizer machine

1 Capacity of plant: 2T-300T/D

2 Products type: 1 or 2 or more kinds.

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

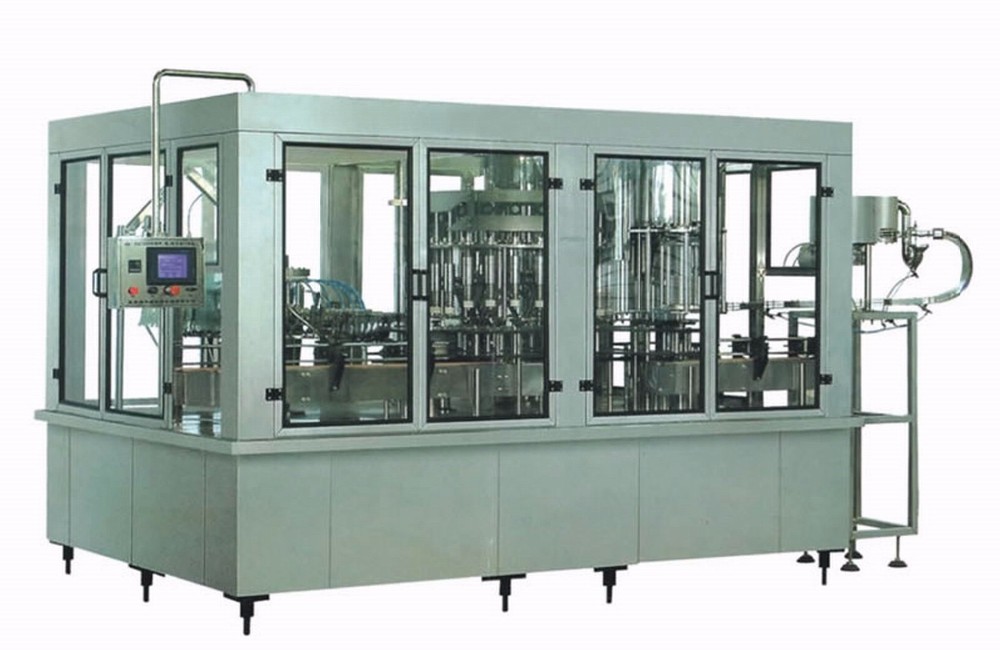

Filling maching

Pre-sales service

We can suggest customer the most suitable machine according to their formula and Raw material. “Design and development”, “manufacturing”, “installation and commissioning”, “technical training” and “after sales service”. We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

After-sale service

1.Installation and commissioning: We will send experienced engineering and technical personnel to be responsible for the installation and commissioning of the equipment until the equipment is qualified to ensure that the equipment is in time and put into production;

2.Regular visits:To ensure the long-term stable operation of the equipment, we will be based on customer needs, provide one to three times a year to come to technical support and other integrated services;

3.Detailed inspection report: Whether the inspection regular service, or the annual maintenance, our engineers will provide a detailed inspection report for the customer and the company reference archive, in order to learn the equipment operation at any time;

4.Fully complete parts inventory: In order to reduce the cost of parts in your inventory, provide better and faster service, we prepared a complete inventory of parts of equipment, to meet customers possible period of want or need;

5.Professional and technical training:In order to ensure the performance of the customer’s technical personnel to become familiar with the equipment, correctly grasp the equipment operation and maintenance procedures, in addition to install on-site technical training. Besides, you also can hold all kinds of professionals to the factory workshops, to help you faster and more comprehensive grasp of technology;

6.Software and consulting services:In order to allow your technical staff to have a greater understanding of the equipment related counseling, I will arrange to send the equipment regularly sent to the advisory and latest information magazine.No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

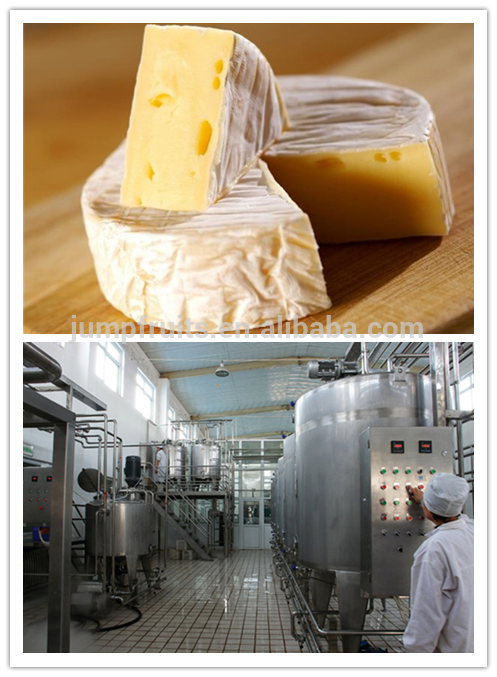

Product detail pictures:

Related Product Guide:

With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for a lot of global consumers for Factory Outlets Thermosetting Bottle Machine - Yogurt Production Line / Milk Processing Plant – JUMP , The product will supply to all over the world, such as: Porto, Doha, United Kingdom, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to deliver the high-quality items and services, and promote lasting cooperation with our customers, common development and create a better future.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.