Factory Outlets Insulation Pipe - Industrial Tomato Powder Production Line From Washing To Packing – JUMP

Factory Outlets Insulation Pipe - Industrial Tomato Powder Production Line From Washing To Packing – JUMP Detail:

Overview

Quick Details

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

N/A

- Model Number:

-

Customized

- Type:

-

Cutter

- Voltage:

-

380V/50HZ

- Power:

-

5.5kw

- Weight:

-

500kg

- Dimension(L*W*H):

-

2100*1460*1590mm

- Certification:

-

CE/ISO9001

- Warranty:

-

One Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

tomato powder production line

- Application:

-

Kinds

- Function:

-

Washing Sterilizing drying

- Material:

-

Food Grade Stainless Steel 304

- Raw material:

-

Fresh Tomato

- Name:

-

Drying Machine

- Feature:

-

High Efficiency

- Item:

-

Industrial Fruit powder Machine

- Usage:

-

Industrial Usage

- Color:

-

Customers' Requirements

Supply Ability

- Supply Ability:

- 5 Set/Sets per Month tomato powder production line

Packaging & Delivery

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- Shanghai

- Lead Time :

- within 3 months after order confirmed

Quick Details

Quick Details

- Condition: New

- Place of Origin: Shanghai, China (Mainland)

- Brand Name: JUMPFRUITS

- Type: Processing line,Turn key solution

- Voltage: 220/380V

- Certification: CE certificate

- Capacity: 60-1500tons/day

- Apply to: fruits & vegetables

- Material: SUS 304 stainless steel

Packaging & Delivery

| Packaging Details: | International export standard packing |

|---|---|

| Delivery Detail: | Within 90 days |

Specifications

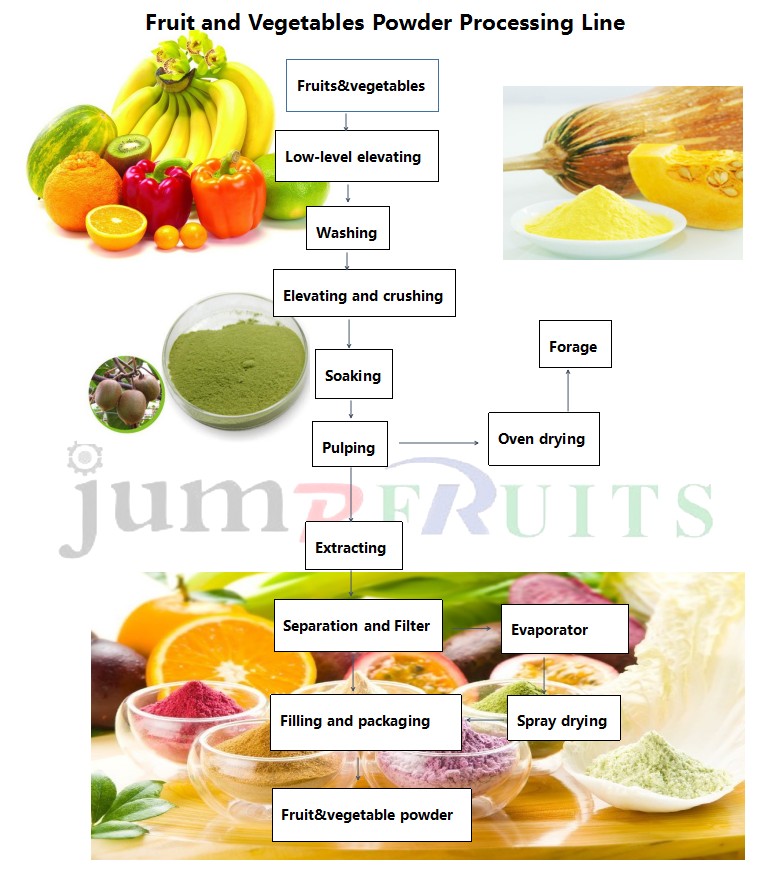

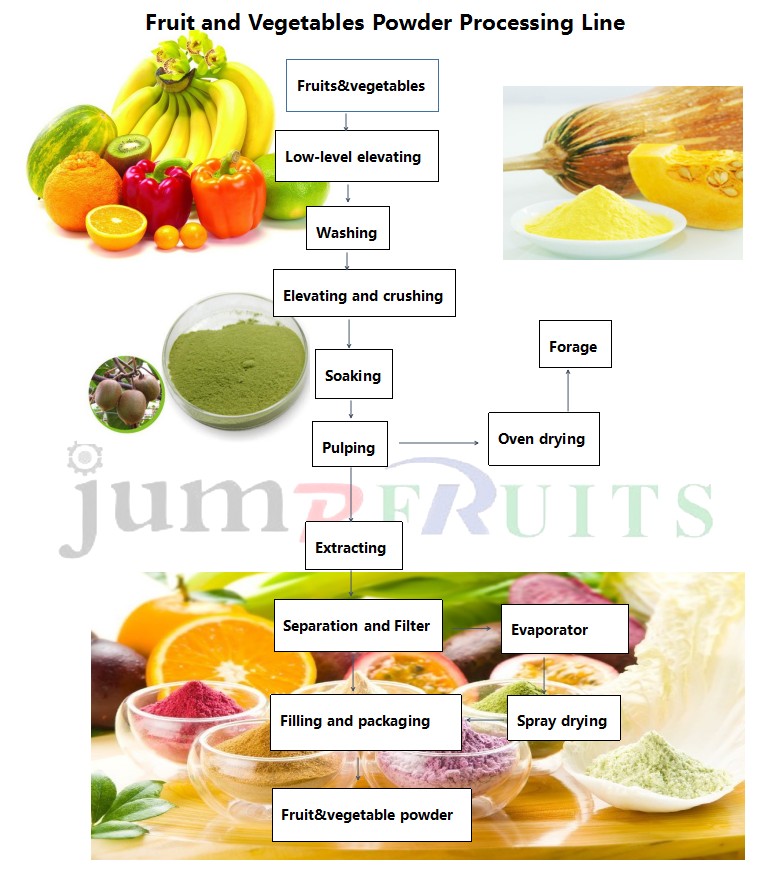

1.automatic tomato powder processing line

2.automatic designing to save labor

3.flexible configuration

4. one year guarantee

General Introduction

Shanghai JUMP Automatic Equipments Co., Ltd . is committed to providing the food processors, suppliers and other customers around the world with leading technology, high-quality product, individual solution and superior service. After nearly 15 years’ innovation and self-development, JUMP has been a leading supplier in China for complete plants of machinery and engineering Vegetables and fruit paste processing, juice<span style="font-family:

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Factory Outlets Insulation Pipe - Industrial Tomato Powder Production Line From Washing To Packing – JUMP , The product will supply to all over the world, such as: Birmingham, Malawi, Grenada, Nowadays our merchandise sell all over the domestic and abroad thanks for the regular and new customers support. We supply high quality product and competitive price, welcome the regular and new customers cooperate with us!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

Write your message here and send it to us

Quick Details

Quick Details