Factory making Small Beer Production Line - Complete Automatic Blueberry Juice Concentrate Processing Line – JUMP

Factory making Small Beer Production Line - Complete Automatic Blueberry Juice Concentrate Processing Line – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

SHJUMP

- Model Number:

-

JPTP-5016

- Type:

-

complete plan for a tomato product engineering project

- Voltage:

-

220V/380V

- Power:

-

depends on whole line capacity

- Weight:

-

depends on whole line capacity

- Dimension(L*W*H):

-

depends on whole line capacity

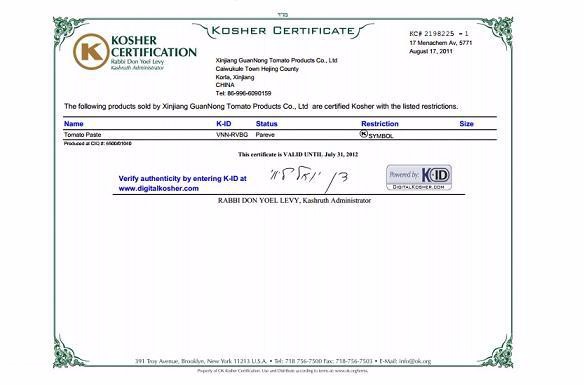

- Certification:

-

CE/ISO9001

- Warranty:

-

1 Year warranty,life-long aftersell service

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Application:

-

complete juice production line

- Name:

-

juice processing project

- Capacity:

-

reasonal design for customer,1T/H to 100T/H

- Material:

-

SUS304 Stainless Steel

- Function:

-

Multifunctional

- Product name:

-

French Fry Cutter

- Usage:

-

Food Processing Industries

- Item:

-

Automatic Fruits Juicer Machine

- Color:

-

Customers' Requirements

- Supply Ability:

- 20 Set/Sets per Month complete production line

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- shanghai port

- Lead Time :

- 2-3 months

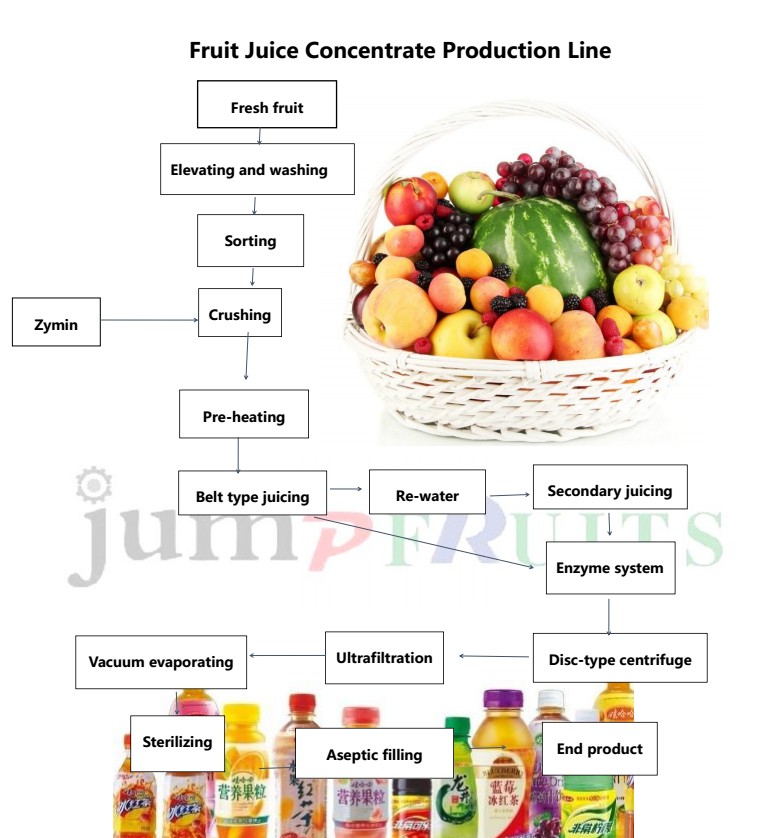

A: promotion system of the original fruits, cleaning system, sorting system, crushing system, pre-heating sterilization system, pulping system, vacuum concentration system, sterilization system, aseptic bag filling system

B: pump → blending drum → homogenization →deaerating → sterilization machine → washing machine → filling machine → capping machine → tunnel spray sterilizer → dryer → coding → boxing

Select stainless steel bracket, food-grade and hard plastic or stainless steel scraper, smoothing blade architecture to prevent the fruit jam; Using imported anti-corrosion bearings, double-sided seal; with continuously variable transmission motor, variable frequency Speed and low operating costsTitle goes here.

Stainless steel roller conveyor, rotation and solution, a full range of check, no need ends. Manmade fruit platform, painted carbon steel bracket,stainless steel antiskid pedal,stainless steel fence.

C. Crusher

Fusing Italian technology, multiple sets of cross-blade structure, crusher size can be adjusted according to customer or specific project requirements, it will increase the juice juice rate of 2-3% relative to the traditional structure , which is suitable for production of onion sauce, carrot sauce, pepper sauce , apple sauce and other fruits and vegetables sauce and products

D. Double-stage pulping machine

It have tapered mesh structure and the gap with load can be adjusted, frequency control, so that the juice will be cleaner; Internal mesh aperture are based on customer or specific project requirements to order

E. Evaporator

Single-effect, double-effect,triple-effect and multi-effect evaporator, which will save more energy; Under vacuum, continuous low temperature cycle heating to maximize the protection of nutrients in the material as well as the originals. There are steam recovery system and double times condensate system, it can reduce the consumption of steam;

F. Sterilization machine

Having obtained nine ed technology, take full advantages of the material’s own heat exchange to save energy– about 40%

F. Filling machine

Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return; Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ; In the filling process,using turntable lifting mode to avoid secondary pollution.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Factory making Small Beer Production Line - Complete Automatic Blueberry Juice Concentrate Processing Line – JUMP , The product will supply to all over the world, such as: Danish, Hungary, Provence, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.