factory customized Canned Radish Equipment - Pasta machine and Spaghetti equipment – JUMP

factory customized Canned Radish Equipment - Pasta machine and Spaghetti equipment – JUMP Detail:

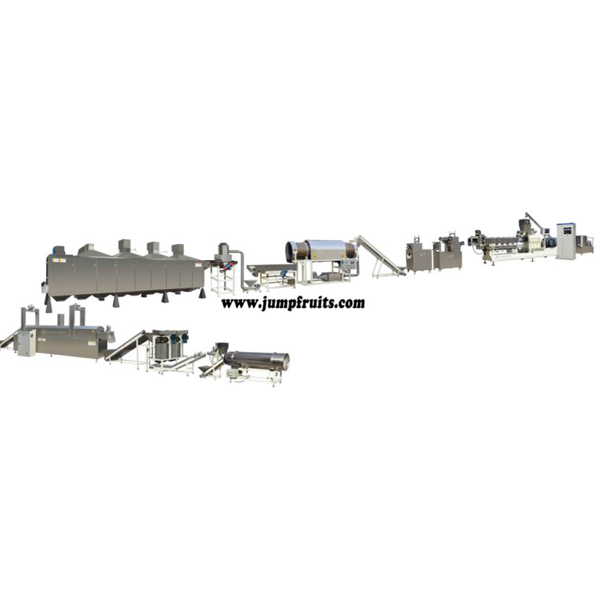

The production line from the raw material ingredients, raw material delivery, extrusion molding, baking until the finished product can be completed at one time. The production line can produce all kinds of pasta, macaroni, round tubes, square tubes, enamel tablets and other products according to the auxiliary equipment. According to the different molds and auxiliary equipments, it can also produce wonderful snack foods such as crispy pieces and potato chips.

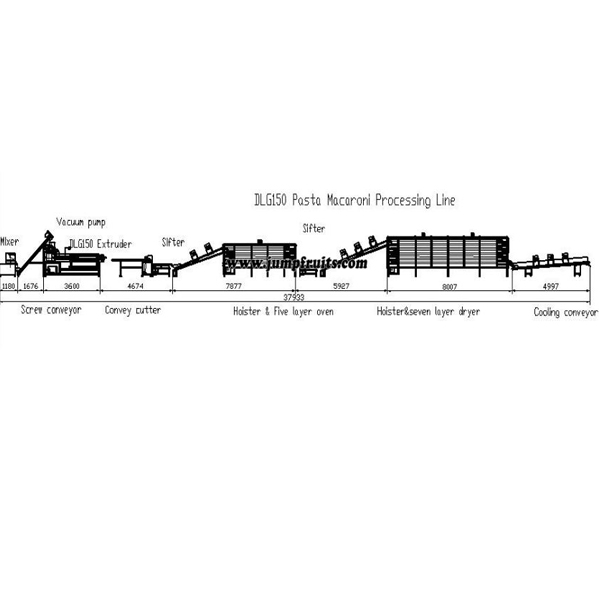

Pasta machine and Spaghetti equipment Process flow

Mixer–Screw conveyor—Extruder–Cutter–Flat conveyor–Hoister–Dyer–Hoister–Dryer–Cooling machine–Packing machine

Pasta machine and Spaghetti equipment components:

1. Mixer: According to the different production lines, different types of mixers are used.

2. Screw conveyor: Uses the motor as a power screw conveyor to ensure quick and convenient loading.

3. Extruder: According to different production lines, different types of extruders are used. The output can be from 100kg/h to 200kg/h. Corn flour, rice flour, flour, and flour can be used as raw materials.

4. Air-sending machine: The wind power of the fan is used to convey the raw materials to the oven, and different fans (or hoisting machines can be selected) according to the different products.

5. Multi-layer oven: oven is mostly electric oven, the temperature is adjusted between 0-200 degrees through the control cabinet, the internal stainless steel double mesh bag, baking time can be adjusted according to speed, there are three layers, five layers, seven layers Stainless steel oven.

Product detail pictures:

Related Product Guide:

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for factory customized Canned Radish Equipment - Pasta machine and Spaghetti equipment – JUMP , The product will supply to all over the world, such as: Spain, Kuwait, Congo, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly solutions, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary products we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly