Factory best selling Dried Tomato Powder Processing Machine - Complete Plan Potato Processing Machinery With New Design – JUMP

Factory best selling Dried Tomato Powder Processing Machine - Complete Plan Potato Processing Machinery With New Design – JUMP Detail:

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JP-XF0019

- Type:

-

complete project

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

800kg

- Dimension(L*W*H):

-

2100*1460*1590mm

- Certification:

-

CE/ISO9001

- Year:

-

2018

- Warranty:

-

1 Year

- Feature:

-

turnkey solution

- Capacity:

-

100kg/h to 10T/H treatment capacity as customer require

- Function:

-

Multifunctional

- Usage:

-

Industrial Usage

- Color:

-

Customers’ Requirements

- Raw material:

-

304 Sainless Steel

- Item:

-

potato chip frying machine

- Supply Ability:

- 20 Set/Sets per Month potato processing machinery

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- shanghai port

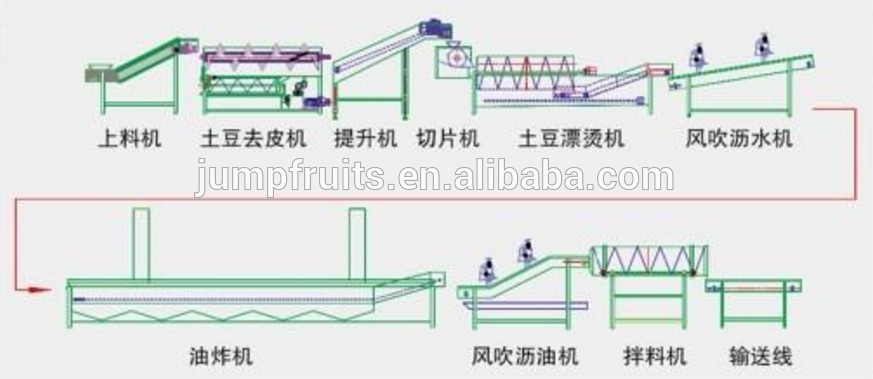

Potato chips production line:

Frozen French fries production line process:

Enhance — Steam Spray — Cleaning Peeling — Select — Cut — Air Bubble Cleaning — Blanching — Dehydration — Frying Machine — De-oiling – - Frozen — Packaging — Storage

Whole line equipment list as follow:

Washing machine —Feeding machine—Peeling machine—-Inspection conveyor—Elevating machine—-Slicing machine—-Blanching machine—-

Heating machine—Dehydrating system—Oil frying machine—Dreg remover—Oil Removing system—-Conveyor—-Oil storage tank—-Seasoning machine —-Pipes, pumps and valves—-Combustion furnace—-Heat exchanger—Steam commutator

Large-size Vertical Packing Machine combine( weight automatically)

JUMP is keeping leadership position in the tomato paste and concentrated apple juice processing line. We also have made brilliant achievements in other fruit& vegetable beverage equipments, such as:

1. Juice production line for orange juice, grape juice, jujube juice, coconut drink/coconut milk, pomegranate juice, watermelon juice, cranberry juice, peach juice, cantaloupe juice, papaya juice, sea buckthorn juice, orange juice, strawberry juice, mulberry juice, pineapple juice, kiwi juice, wolfberry juice, mango juice, sea buckthorn juice, exotic fruit juice, carrot juice, corn juice, guava juice, cranberry juice, blueberry juice, RRTJ, loquat juice and other juice drinks dilution filling production line

2. Can food production line for canned Peach, canned mushrooms, canned chili sauce, paste, canned arbutus, canned oranges, apples, canned pears, canned pineapple, canned green beans, canned bamboo shoots, canned cucumbers, canned carrots, canned tomato paste, canned cherries, canned cherry

3. Sauce production line for mango sauce, strawberry sauce, cranberry sauce, canned hawthorn sauce etc.

We grasped proficient technology and advanced biological enzyme technology, successfully applied in more than 120 domestic and foreign jam &juice production lines and we has helped client gain excellent products and good economic benefits.

Our unique–Turnkey Solution.:

No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Consulting + Conception

As a first step and prior to project implementation, we will provide to you profoundly experienced and highly competent consulting services. Based on an extensive and thorough analysis of your actual situation and requirements we will develop your customized solution(s). In our understanding, customer-focused consultation means that all steps planned – from the initial conception phase to the final phase of implementation – will be conducted in a transparent and comprehensible manner.

Project Planning

A professional project planning approach is a prerequisite for the realization of complex automation projects. On the basis of each individual assignment we calculate time frames and resources, and define milestones and objectives. Due to our close contact and cooperation with you, in all project phases, this goal-oriented planning ensures the successful realization of your investment project.

Design + Engineering

Our specialists in the fields of mechatronics, control engineering, programming, and software development closely cooperate in the development phase. With the support of professional development tools , these jointly developed conceptions will then be translated into design and work plans.

Production + Assembly

In the production phase, our experienced engineers will implement our innovative ideas in turn-key plants. The close coordination between our project managers and our assembly teams ensures efficient and high-quality production results. After the successful completion of the test phase, the plant will be handed over to you.

Integration + Commissioning

In order to reduce any interference with associated production areas and processes to a minimum, and to guarantee a smooth set-up, the installation of your plant will be conducted by the engineers and service technicians who have been assigned to and accompanied the individual project development and production stages. Our experienced staff will ensure that all required interfaces work, and your plant will be successfully put into operation.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Product detail pictures:

Related Product Guide:

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for Factory best selling Dried Tomato Powder Processing Machine - Complete Plan Potato Processing Machinery With New Design – JUMP , The product will supply to all over the world, such as: South Korea, United Arab Emirates, Namibia, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.