Best quality Blending Equipment - Industrial Dried Mango Processing Machine – JUMP

Best quality Blending Equipment - Industrial Dried Mango Processing Machine – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

HPF-DFM003

- Type:

-

one – stop service

- Voltage:

-

380V

- Power:

-

depends on machine capacity

- Weight:

-

500kg

- Dimension(L*W*H):

-

adjusted based on your factory design

- Certification:

-

CE ISO

- Warranty:

-

12 Months

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

dried mango processing machine

- Material:

-

SUS304

- Function:

-

whole processing line

- Usage:

-

dried fruits processing and packing

- Raw material:

-

fresh mango, pear, lemon, apple, pineapple

- Application:

-

Mango

- Name:

-

dried mango slice processing machine

- Feature:

-

Easy Operation

- Capacity:

-

500kg/h-30t/h

- Item:

-

Industrial Fruit Dehydrator

- Supply Ability:

- 10 Set/Sets per Month dried mango processing machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.Mobile/whatsapp:+8618018520615

- Port

- Shanghai Port

- Lead Time :

- 60 days

This fruit processing line is suitable for dried fruit,such as,dried apricot,raisin,olive,prune,and so on.

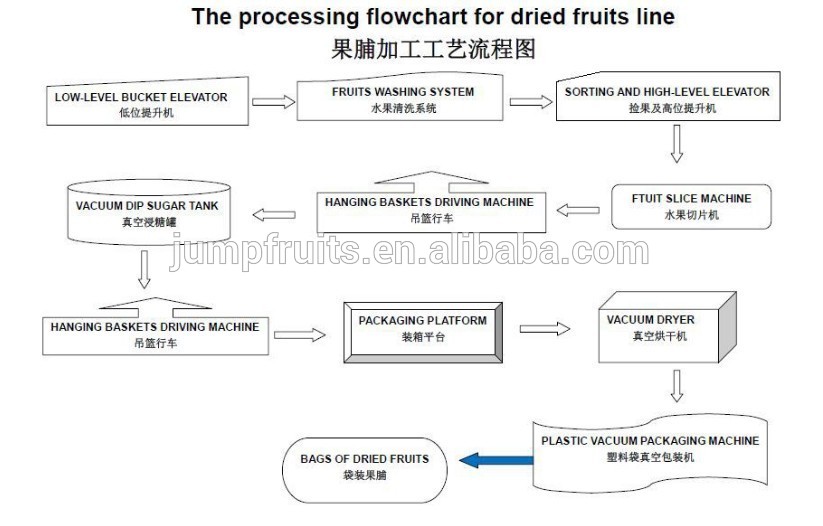

It is a Processional dried fruit processing line. Flow chart includes:

Improve feeding machine– rotary drum washing machine–buble washing machine–vibrating machine for water–conveyor–mesh belt drying machine

Whatsapp/Wechat/Mobile: 008613681836263 Welcome any inquiry!

Product Application

Raw materials: fresh fruit (mano,apple, kiwi,apricot,grape,olive,prune)

The final product: dried mango,apple ,kiwi, apricot,raisin,olive,prune,and so on

Fresh tomato treatment: 0.5-500 tons/hour of fresh fruits(per customer requirement)

Tomato paste output: 0.1-100 tons/hour(depends on fruit type, brix,etc.)

Main Features

we take advantages of the comprehensive and technical cooperation with the Italian company partner, now in fruit processing, cold breaking processing, multi effect energy saving concentrated, sleeve type sterilization and aseptic big bag canning has made domestic and unmatched technical superiority. We can provide the entire production line processing 500KG-1500 tons of raw fruit daily according to the customers.

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of “Quality and Service Branding”, after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

JUMP is keeping leadership position in the tomato paste and concentrated apple juice processing line. We also have made brilliant achievements in other fruit& vegetable beverage equipments, such as:

1. Juice production line for orange juice, grape juice, jujube juice, coconut drink/coconut milk, pomegranate juice, watermelon juice, cranberry juice, peach juice, cantaloupe juice, papaya juice, sea buckthorn juice, orange juice, strawberry juice, mulberry juice, pineapple juice, kiwi juice, wolfberry juice, mango juice, sea buckthorn juice, exotic fruit juice, carrot juice, corn juice, guava juice, cranberry juice, blueberry juice, RRTJ, loquat juice and other juice drinks dilution filling production line

2. Can food production line for canned Peach, canned mushrooms, canned chili sauce, paste, canned arbutus, canned oranges, apples, canned pears, canned pineapple, canned green beans, canned bamboo shoots, canned cucumbers, canned carrots, canned tomato paste, canned cherries, canned cherry

3. Sauce production line for mango sauce, strawberry sauce, cranberry sauce, canned hawthorn sauce etc.

We grasped proficient technology and advanced biological enzyme technology, successfully applied in more than 120 domestic and foreign jam &juice production lines and we has helped client gain excellent products and good economic benefits.

Spray cleaning machine

Main characteristic:

1 Used to wash freshGuava, tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

Motor Power: 3KW

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

Specially for the fruit paste ,syrup and other high-viscosity products. Continuous low-temp evaporation under vacuum to ensure the least loss of the efficient substance insides. Incorporated Italian technology and made as per Europe stand. Have more experienced in producing the unit. More than 70 lines in china and world wide run smoothly. The processing capacity ranging from 300L-35000L water evaporated per hour by means of single effect or double effect or triple effect vacuum evaporator

The unit is composed of tubular heater, vacuum evaporation chamber, multi-stage condenser, pumps, PLC control system, valves, meters& gauges, operation platform, etc.

Compacted structure,stable running,high efficiency and energy-saved performance.

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

Tube in tube sterilizer

1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

2. Incorporated Italian technology and conform to Euro-standard

3. Great heat exchange area, low energy consumption and easy maintenance

4. Adopt mirror welding tech and keep the smooth pipe joint

5. Auto backtrack if not enough sterilization

6. CIP and auto SIP available together with aseptic filler

7. Liquid level and temp controlled on real time

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for Best quality Blending Equipment - Industrial Dried Mango Processing Machine – JUMP , The product will supply to all over the world, such as: Costa rica, Ghana, Latvia, We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.